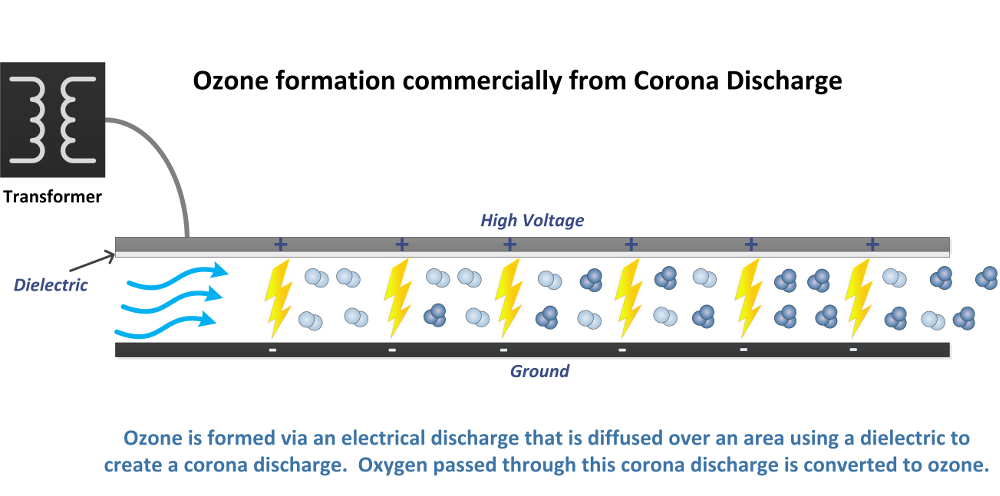

COMMERCIAL OZONE PRODUCTION FROM ELECTRICAL DISCHARGE

The most common method of producing ozone commercially and industrially is electrical discharge, or corona discharge. A corona discharge is simply a diffused spark through a dielectric to spread out that electrical discharge to a large area for maximum efficiency.

There are many types and styles of corona discharge ozone generators. These go by many names, but are fundamentally the same, using these components:

- Corona cell using a dielectric

- Dielectric material may be glass, ceramic, or quartz

- Dielectric may be conical, or flat plate

- High voltage transformer to increase voltage of the electrical discharge

- Power supply to regulate power to transformer

- 60Hz machines will only regulate the voltage to the transformer

- High frequency machines (greater than 60 Hz) will regulate frequency and/or voltage to transformer

ADVANTAGES OF CORONA DISCHARGE OZONE GENERATOR

- Scalable and can create very large amounts of ozone

- Creates ozone at medium to high ozone concentrations (up to 30% by weight)

- Cost effective for long term operation

- Low maintenance

DISADVANTAGES OF CORONA DISCHARGE OZONE GENERATOR

- High cost for initial capital investment

- Creates excess heat that must be removed for efficient operation

- Requires very clean, dry air/oxygen feed-gas for reliable operation

Hello,

We are considering the use of Quartz tube ozone generator and ceramic plate ozone generator in an air treatment device which is under development.

In a recent series of experiments, we got consistent and stable ozone concentrations when working with quartz tube whilst we couldn’t get the same readings with ceramic plates generator. We suspect that it is due to our ability to remove the heat from the quarts tube efficiently whereas it is a bit more complicated to be done in the current set up with ceramic plate.

Would you be able to advise what and if there are any disadvantages when working with tube generator for air applications?

Thanks for your help.

Cheers,

Ortal

Ortal,

Likely the humidity in ambient air played a large part in your ozone generation consistency. Humidity will affect ozone output for a variety of reasons. Long term nitric acid (HNO3) will be formed due to the hydrogen in the air mixing with the nitrogen and ozone. In the short term however, humidity will affect the ability to create a consistent corona, and create hot spots on the dielectric. Ceramic is much more prone to these hot spots than quartz glass. Also, the HNO3 and other nitrogen by-products can adhere to the ceramic easier than the quartz. Therefore, the quartz will be more consistent than the ceramic both short, and long-term.