You’ll Know You’re Getting Chemical Free Home Water Disinfection When …

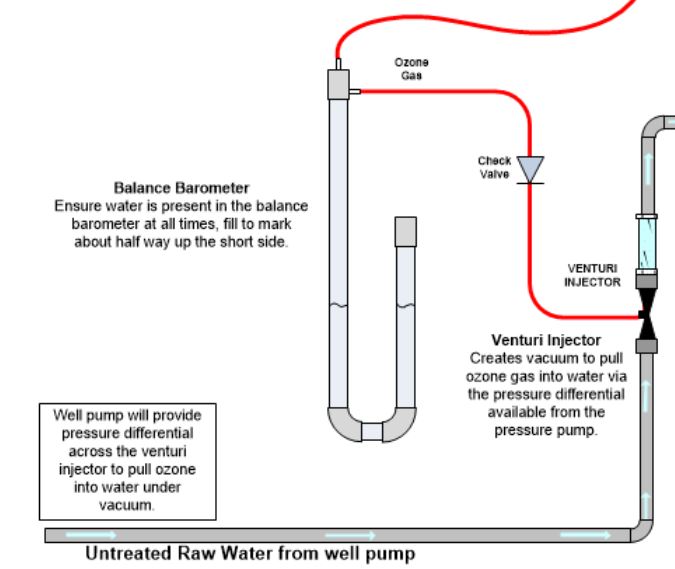

Ozone has been used to disinfect water for over 100 years. Many water treatment plants throughout the world not only use ozone to disinfect water, …

You’ll Know You’re Getting Chemical Free Home Water Disinfection When … Read More »