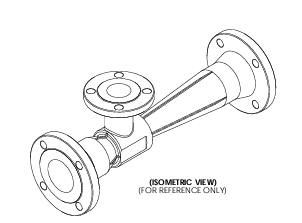

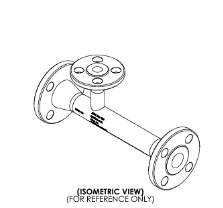

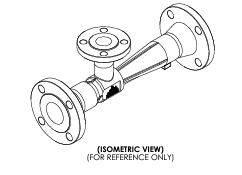

Enhancing Ozone Dissolution with CF3M Stainless Steel Venturi SS-3090

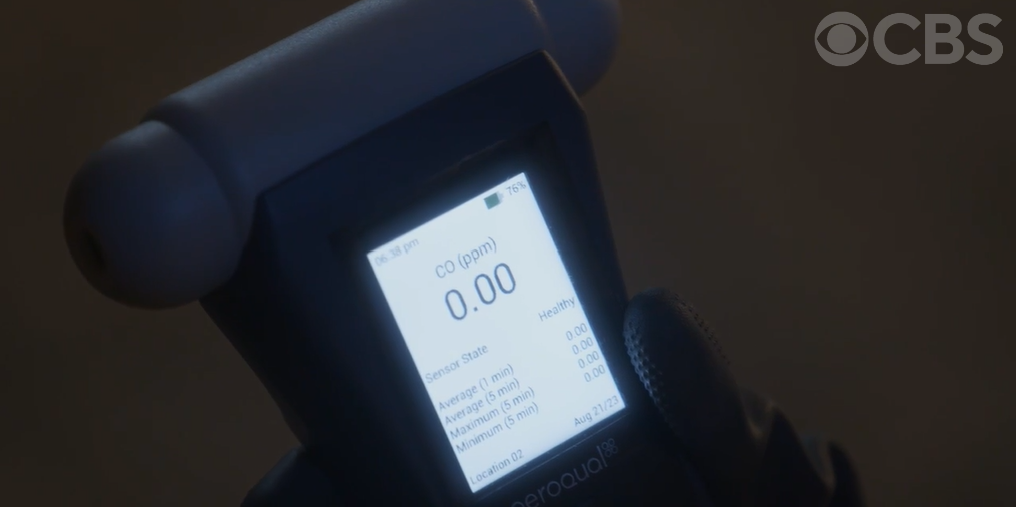

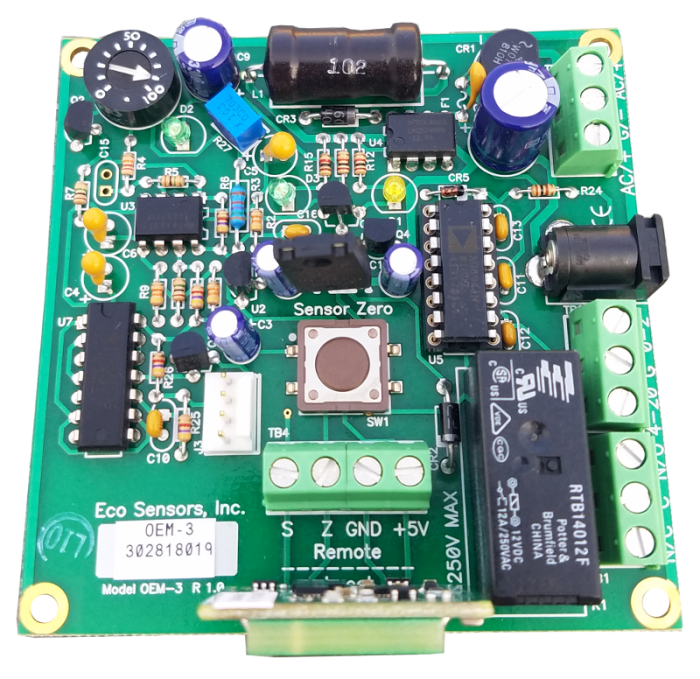

Unleashing Ozone Dissolution Efficiency Ozone gas plays a vital role in water treatment processes, offering powerful disinfection capabilities. However, achieving efficient ozone dissolution into water …

Enhancing Ozone Dissolution with CF3M Stainless Steel Venturi SS-3090 Read More »