Ozone Monitor Calibration

All sensors require a yearly calibration to ensure your gas measurements are accurate and performing within manufacturer standards. This page is desiccated to the individual manufacturers we represent and their specific calibration procedures.

** Calibration Service Request Form **

|

Calibration Frequency: Most ozone sensor manufacturers will recommend calibration annually. This would be the longest interval Oxidation Tech would recommend for ozone sensor calibration. Frequency of calibration will be depending upon the sensor type, and purpose of the gas sensor. Our general recommendation would be to perform a bump-test of the sensor at least monthly. Perform a field or factory calibration or sensor check every 6-months, and a factory calibration or sensor replacement every 12-months. |

|

|

Calibration Costs: Calibration costs do vary, see below to get an estimate: Calibration Fee: $150 Analyzer Calibration Fee: $300 PM Calibration Sensor Fee: $330 Genie Calibration Fee: $265 ATI Calibration Fee: $205 ** note that prices are subject to change per labor and parts required. |

|

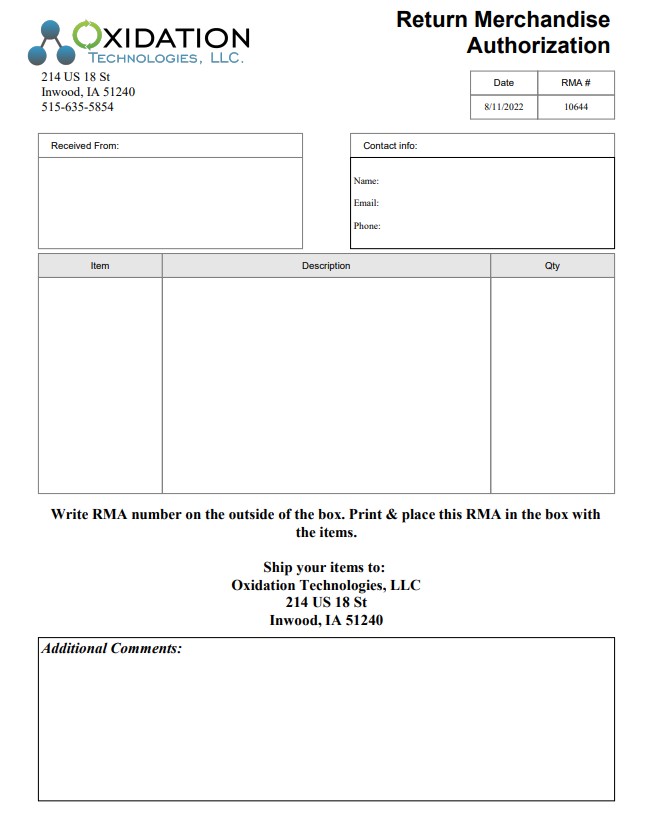

The RMA Process: Please click the link to fill out the following form: Calibration Service Request Form Once this is filled out, please email it back to: [email protected] to get a RMA number. Once you receive an RMA number, please print off the form and mail your items to us. Please include any important information, such as: serial number, issues with sensor, errors on the display. We will contact you once we have evaluated/calibrated your sensor for payment. Please note that any sensors that fail calibration will not be returned in regards to liability. Please reach out to us if you have any questions. |

RMA Example RMA Example |

306 Ozone Calibration Source 306 Ozone Calibration Source |

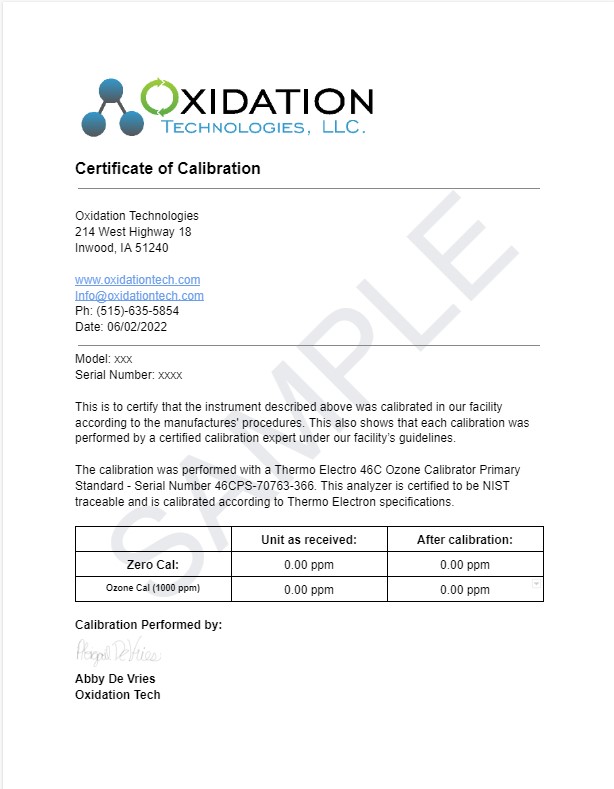

Our Calibration Equipment: All our gasses and equipment are NIST traceable. Have you ever wondered who ensured 1 pound is exactly 1 pound? And 1 meter is precisely 1 meter? The NIST is the answer. This is the governing board that will hold the standard of measurement. Every gas measurement calibration standard must be directly traceable to the NIST to ensure your sensor's calibration is accurate. When you are reviewing your calibration certificate it must be clearly stated that the calibration standard used to calibrate your sensor is NIST traceable. If necessary, you can, and should request the proper documentation to validate that traceability. Calibration gasses can also be NIST traceable. The NIST has set-up specific protocols for the manufacturer of calibration gasses to follow to ensure your calibration gas can be provided with NIST traceability. |

|

Calibration Certificate: A calibration certificate is provided by the manufacturer when you purchase a sensor. The calibration certificate provides you with the necessary information to prove that the sensor was calibrated to an NIST standard. The Calibration Certificate will provide the date the sensor was calibrated, and the date calibration should be done again. |

|

|

A23-14 Calibration Kit |

Field Calibration: Field calibration is just what it indicates. Any calibration of a sensor performed in the field, or where the sensor is currently installed. This can be performed with calibration gasses, or with devices designed to produce gasses that will react properly to ensure calibration is accurate on your sensor. Field calibration is convenient for applications where many sensors are installed and would be challenging or inconvenient to send away for calibration. Field calibration of your sensors can be performed by Gas Sensing, and many other service companies that will calibrate, and repair your sensors. |

|

Bump Testing: When you want to know if your sensor is responding a bump test is a great option. This is simply a test that exposes the sensor to the specific gas it is intended to measure and ensure that the sensor does indeed respond. While not a precise process, this does ensure that the sensor is indeed responding and can respond in a critical situation where human safety is critical. ATI offers an Auto-Test generator for many of the sensors used on the D12 and F12 monitors. This auto-test generator will produce a gas that cause the proper sensor to react. A test is run on a pre-set schedule, if the gas sensor does not respond as expected an alarm will come on indicating the sensor has failed. This is a great option for gas sensing is critical applications. Note: A bump-test is not an acceptable replacement for sensor calibration |

Ozone Puffer |