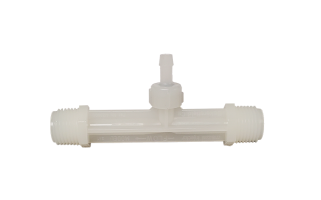

Venturi Injector

Mazzei Venturi Injector for ozone injection into water:

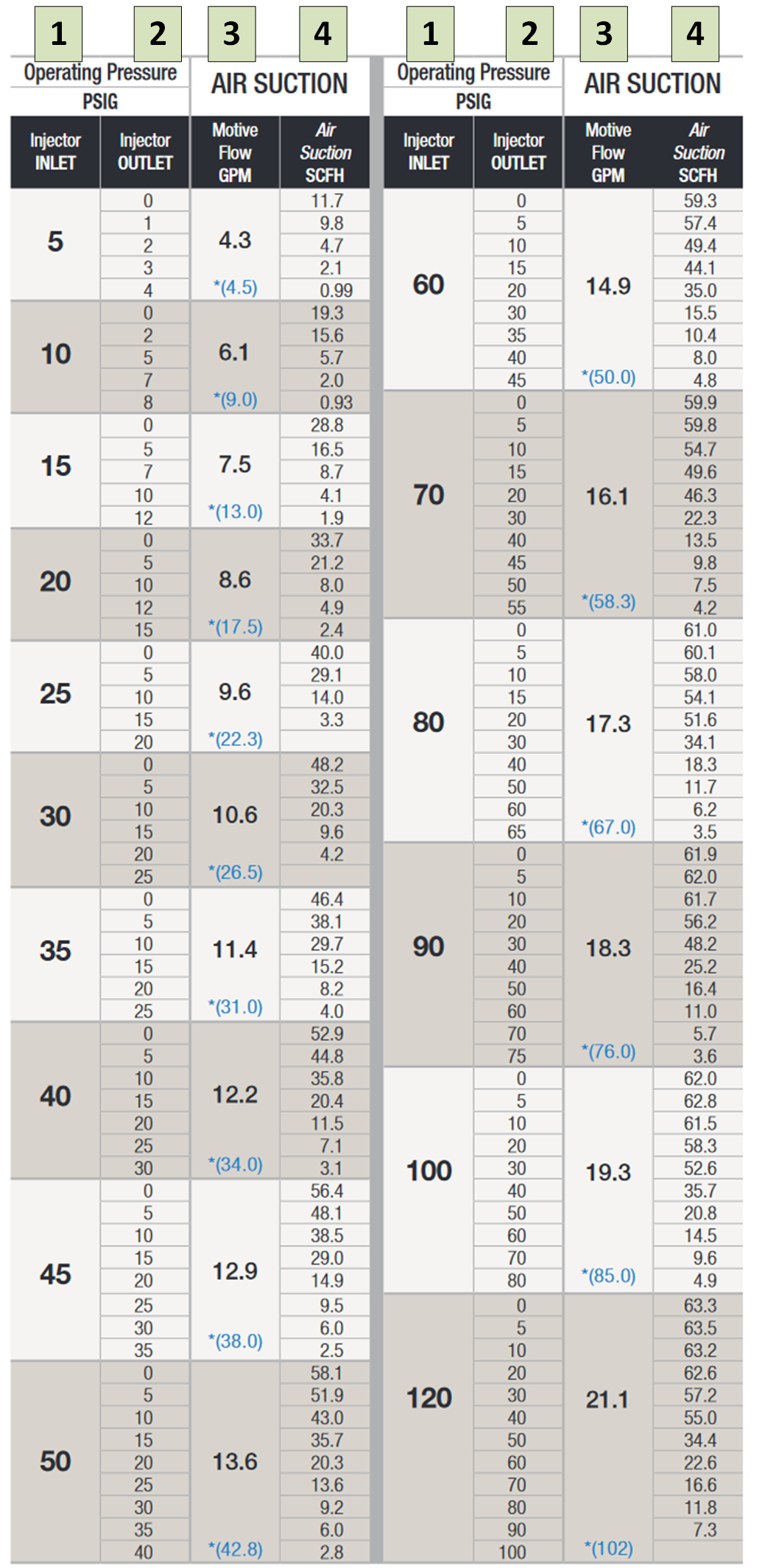

The Mazzei Venturi Injector is simply the best device available to introduce ozone gas into water efficiently. Chart below shows all Black Kynar (PVDF) Mazzei Venturi's.

We do carry the full line of Mazzei venturis, if you don't see what you are looking for, please call our sales staff.

Choosing Between Natural and Black Kynar Venturi:

Black Kynar:

Black Kynar venturis are pigmented with carbon black, offering improved UV resistance over their natural counterparts. This pigmentation not only enhances their aesthetic appeal but also provides practical benefits such as reduced staining and lower costs.

Advantages of Black Kynar Venturis:

- Enhanced UV resistance

- Aesthetic appeal with less staining

- Cost-effectiveness

Applications for Black Kynar Venturis:

- Industrial ozone systems

- Outdoor applications due to improved UV resistance

Natural Kynar:

Natural Kynar venturis, devoid of pigmentation, offer their own set of advantages. While they may lack the enhanced UV resistance of black Kynar, they are preferred in certain applications where transparency or specific material properties are paramount.

Advantages of Natural Kynar Venturis:

- Suitable for drinking water and ultra-pure water applications

- Some transparency for visual indication of system operation

- Higher temperature resistance and heat dissipation

Applications for Natural Kynar Venturis:

- Drinking water and ultra-pure water applications

- High-temperature environments requiring superior heat dissipation

Making the Right Choice:

When selecting between natural and black Kynar venturis, it's essential to consider the specific requirements of your application. If UV resistance and aesthetics are crucial, black Kynar may be the preferred option, especially for industrial settings and outdoor installations. However, for applications where purity, transparency, or heat dissipation are paramount, natural Kynar emerges as the optimal choice.

In conclusion, both natural and black Kynar venturis offer exceptional performance and durability in diverse industrial applications. By understanding their respective strengths and applications, you can make an informed decision that aligns with your project requirements, ensuring optimal performance and longevity.

Click on image to view full specifications

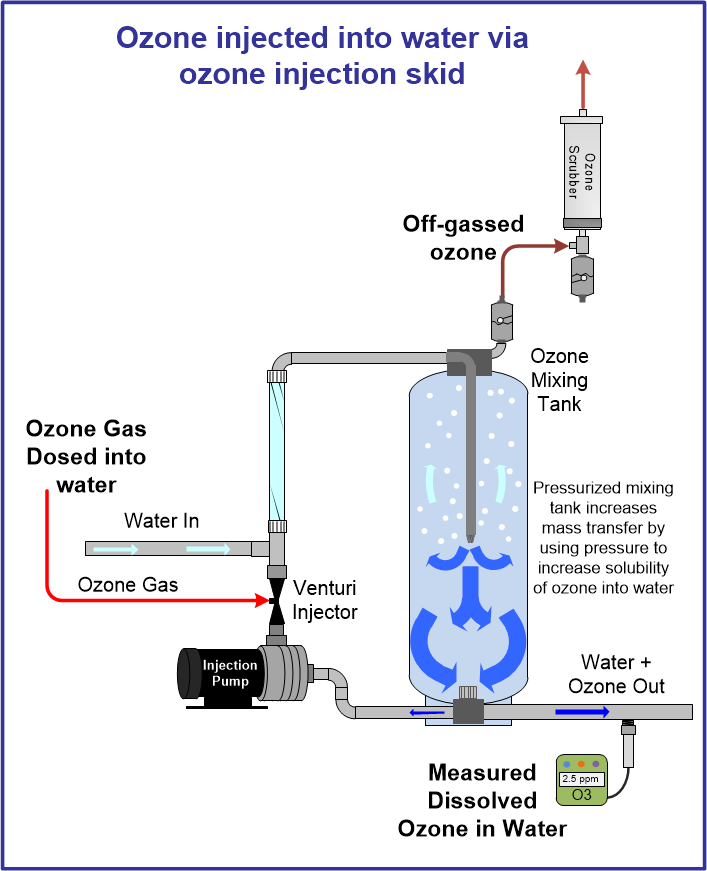

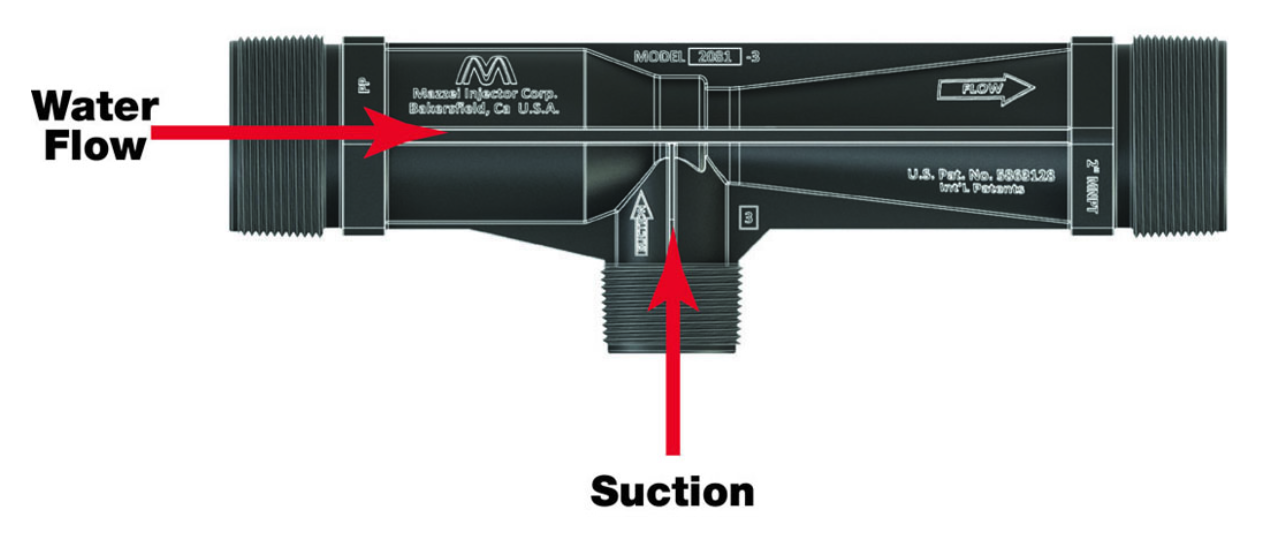

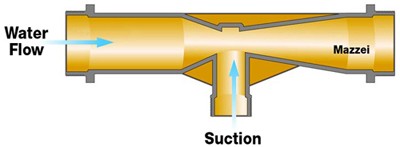

How a Venturi Injector Works:

Click HERE to see a video on how the venturi injector works

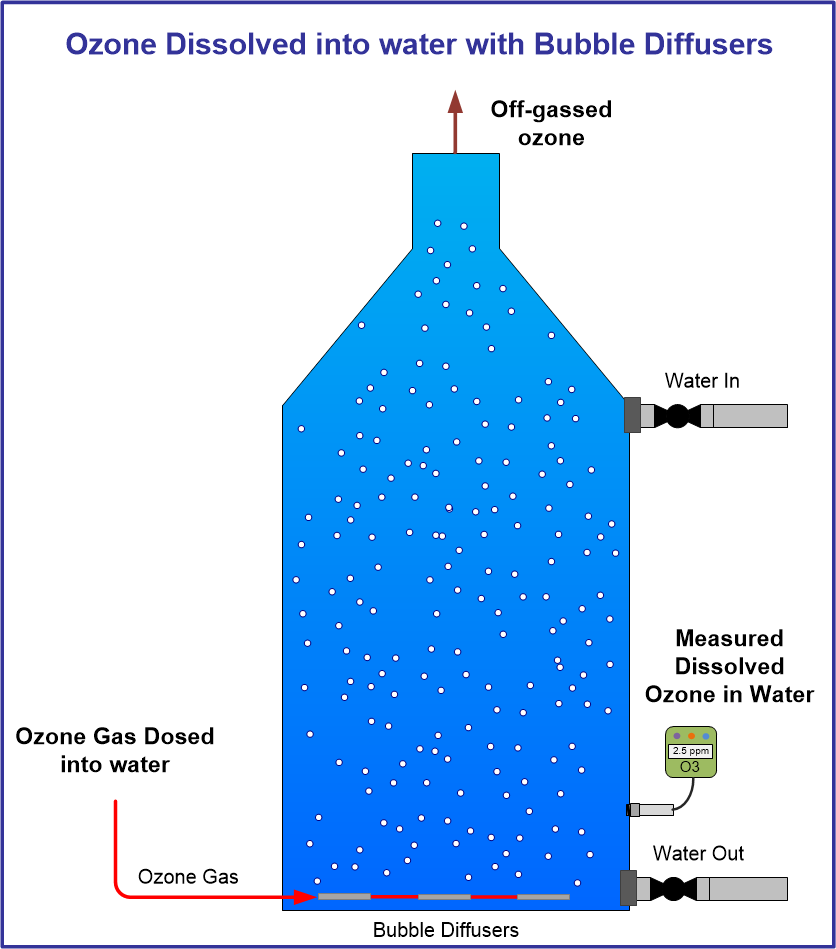

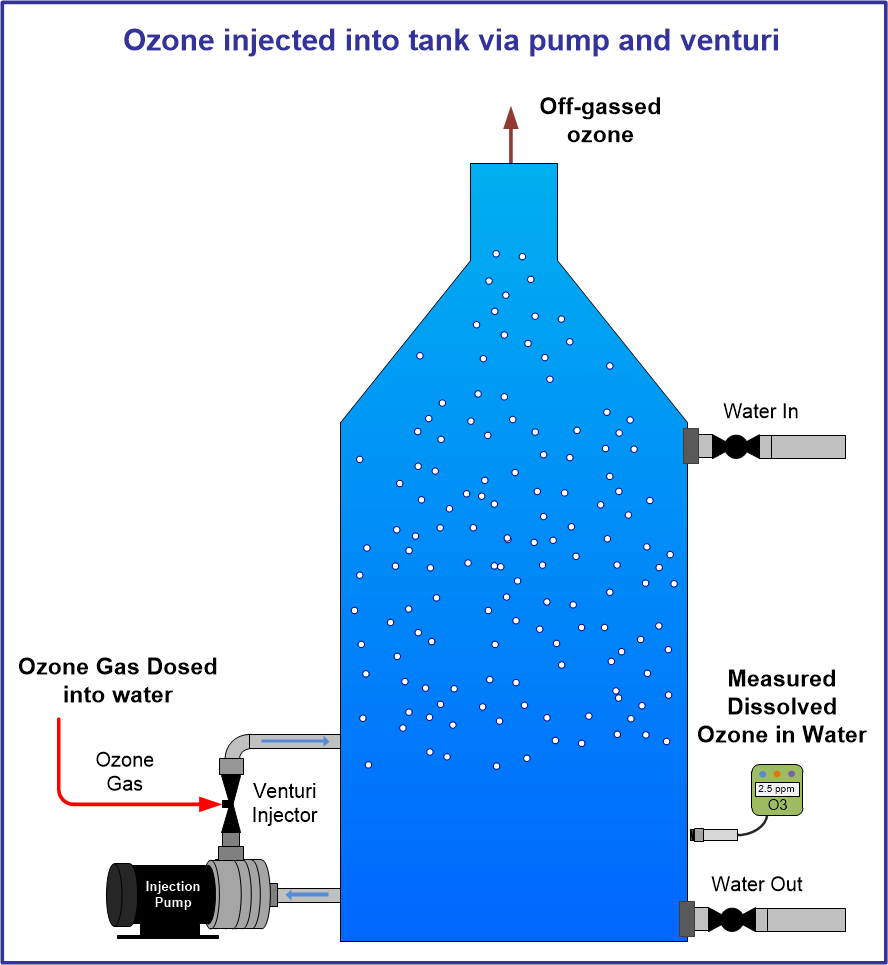

A venturi injector pulls ozone/oxygen gas into the water stream under a vacuum and dissolves that ozone/oxygen gas into water very efficiently. A pressure differential across the orifice in the venturi creates a high-velocity jet stream of water. This high velocity of water results in a decrease in absolute pressure and creates a vacuum on the third leg, or gas suction let. This gas is quickly and efficiently dissolved into the water directly after this venturi.

Ozone/Oxygen gas is pulled into the water. The gas fills the void created by the suction action of the venturi to entrain the gas bubbles into water very efficiently.

Tech Notes:

-Complete Mazzei Venturi Injector Performance Tables (all mazzei venturi's are in one table)

-Tech Note - Injector Troubleshooting Guide

-Tech Note - Injector Ozone to Water Mixing

-Tech Note - Correction Factor for Gas Flow When Gas is Under Pressure

-Tech Note - Injector by-Pass Assembly

-Tech Note - Supplemental Check Valves

-Tech Note - Handling Solids During Injector and Nozzle Mixing

-Tech Note - Installation Notes

-Tech Note - Pressurized Sprinkler Applications

-Tech Note - Pressurized Water Line Applications

-Tech Note - Removal of Hydrogen Sulfide by Aeration

-Tech Note - Removal of Iron and Manganese by Aeration

-Tech Note - Water-Well/Pressure Tank Applications

Additional Information: