Ozone Exposure Testing

Oxidation Technologies provides ozone exposure testing services for many applications.

What is Ozone Exposure Testing?

Ozone Exposure Testing is a method used to determine the effect of a material exposed to ozone gas. This is accomplished using an Ozone Chamber with precise instrumentation and controls to create this environment. This test method can be used to estimate the life span of the material under normal conditions. This is called Accelerated Age Testing.

Other applications include:

Quality Assurance Testing

Research & Development

Odor removal

Scientific Research

Ozone Exposure Testing:

We have the tools and expertise to perform the ozone exposure portion of the test.

Oxidation Tech uses a calibration chamber with a dual beam ThermoFichsher Ozone Analyzer to create and measure ozone levels. This chamber is used for all in-house ozone sensor calibrations as well as Ozone Exposure Testing. We can run these exposure tests from 0-1000 PPM and up to 105 Degrees Fahrenheit.

We can perform the exposure testing from hours to weeks if needed. All exposure testing includes a graph and raw data of ozone, temperature, and humidity levels.

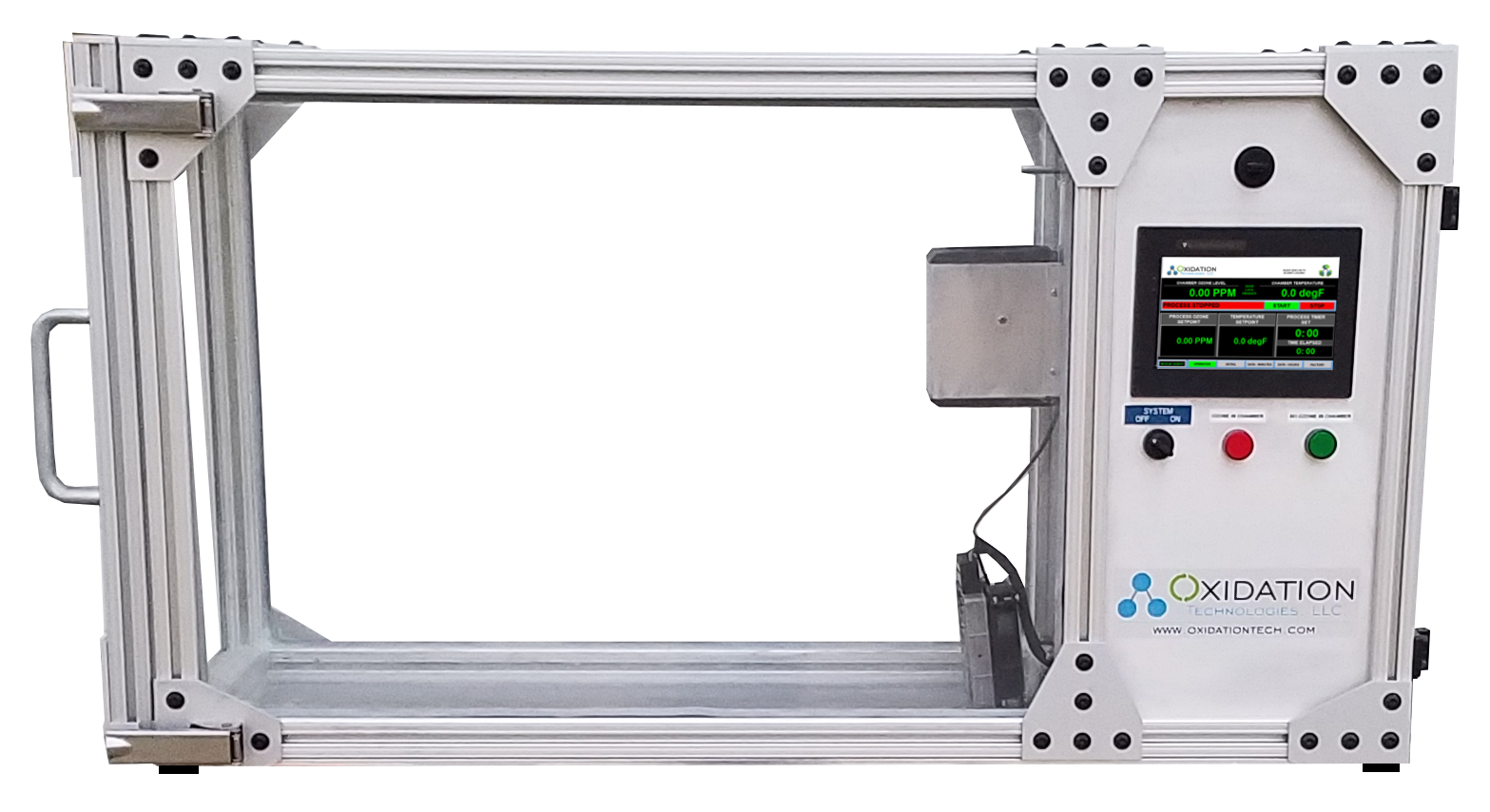

Example of one of our ozone chambers in use:

JIS K6259 standards

ISO 1431

MIL-STD-202G

MIL-STD-1344

SAE J1455

SAE J517

SAE J1401

ASTM D1149-07

ASTM D1149-99

ASTM D1171

ASTM D3395

ASTM D4575

ASTM D518

ASTM D380

FMVSS 106

EIA-364-14

TP-14B

Ozone in water testing:

We can also offer ozone testing in water. Materials can be placed in water containing ozone at a specified ozone level and temperature for any period of time necessary. We have exposed materials to water in a bath, or pumped water containing ozone through parts if necessary.

Perform your own testing:

Oxidation Tech also builds Environmental Testing Chambers to our customer's specifications. If you prefer the ability to perform ozone exposure testing on-site view our ozone chambers HERE.

Should you have any questions about our ozone exposure testing services, please contact us.

Example of one of our ozone chambers in use: