ATI Sensor Calibration

Analytical Technologies Incorporated (ATI)

This information applies to the sensor module used in the C16, F12, and D12 Monitors.

ATI Smart Sensors come pre-calibrated and have all calibration information loaded on the sensor. The sensor can be swapped between monitors without any special requirements for proper calibration.

Sensors are fairly low cost and are replaced annually to remain in calibration. Periodic bump tests can be performed to ensure the sensor is still operating, but no calibration is typically necessary.

Calibration Frequency

While the transmitter itself requires no periodic calibration, H10 sensors should be “zero” and “span” calibrated every 3-6 months, based upon environmental factors. Sensors frequently exposed to dirt, oil mist, vapors, or very dry air, may require more frequent calibration.

Zero Calibration

As the name implies, zero calibration corrects the transmitter reading to zero in the absence of any reactive gas. During zero calibration, the transmitter offset error is stored, and subsequently subtracted from future readings. ATI recommends bottled zero gas as a source, which should be selected based on the type of sensor. For example, bottled “Zero” Air may be used to zero Chlorine sensors, but Oxygen sensors require bottled Nitrogen gas.

Span Calibration

The role of span calibration is to correct the transmitter reading to a known concentration of target gas (the gas for which the sensor was designed to monitor). During span calibration, the transmitter effectively stores the slope of the error, and divides it out of subsequent readings. Sensors for most gases, such as Ammonia, require a bottled “span gas” source. This applies even to Oxygen sensors, where the span gas source is bottled zero air.

Calibration Terminology

The zero calibration is referred to as, “zero”, “zeroing”, and “zeroed”. Likewise for the span calibration, which appears as, “span”, “spanning”, and “spanned”. As with most instruments, zero calibration should be performed before span.

Calibration Kits

Calibration kits, containing zero and span bottle gas sources, are available from ATI for many toxic gases. Contact Gas Sensing, if you have questions about calibration gas kits or gas sources.

ATI does provide a special kit for ozone gas calibration as ozone cannot be supplied in a calibration gas cylinder. The A23-14 can be used for all ATI ozone products along with other ozone sensors. Contact gas sensing for details.

Indications During Sensor Calibration

The “un-blanked” gas concentration value is displayed during zero and span calibration, primarily to observe any slight amount of positive or negative drift. In addition, alarms are cleared and inhibited, and the 4-20mA output of the F12 transmitter is locked at 4.0mA (transmitters equipped with Oxygen sensors are locked at 17.4mA, representing normal, 20.9% atmospheric Oxygen). The 4-20mA output will not change when gas is applied and removed, and for 15 minutes thereafter (the default value). While viewing the calibration pages, the LCD display will indicate the changing gas concentration.

Calibration Exceptions

Zero and span calibration are not allowed during the following conditions: v Sensor removed, or in 5-minute8 warm-up period v Transmitter fault is active v Auto-test is active (“A” status indicator appears on Main Display page) To help prevent errors, zero and span are not allowed if the sensor output, or span value entered, is too high or too low. Memory errors are reported if detected while updating the sensor or transmitter memory.

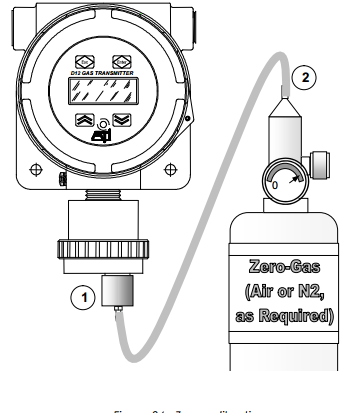

Zero Calibration Procedure

Performing a zero calibration requires bottled “Zero-gas” with a 500 cc/min regulator, calibration adapter, and a convenient length of ¼” tubing. The gas used depends on the type of sensor installed. For example, an H2S sensor may be zeroed with Zero-air, while Oxygen sensors must be zeroed with Nitrogen. In some cases, a sensor may be zeroed directly to the atmosphere, but only when it is known to be free of reactive gasses. Check with the factory if you are uncertain about which gas to use.

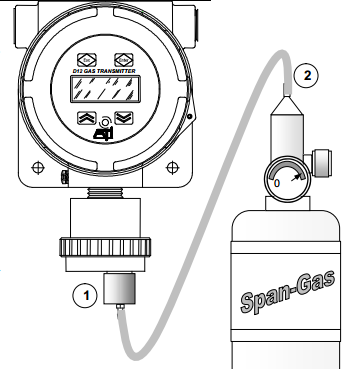

Span Calibration Procedure

Span calibration* requires bottled “span-gas” with a 500 cc/min regulator, calibration adapter, and a convenient length of ¼” tubing. The gas type and concentration used depends on the type of sensor installed. Check with the factory if you are uncertain about which gas to use.

Sensor Calibration Records

A calibration record is written into the sensor memory each time a zero or span calibration is performed, and when a calibration Undo is performed. Enough memory is reserved for 63 zero calibrations and 63 span calibrations. Zero and span calibration records are accessed on the Cal_History page.

Auto-test

The Auto-test option verifies the serviceability of the transmitter on a prescribed schedule by exposing the sensor to a small amount of gas, and verifying a minimum response. Three attempts per test are made, and if the sensor does not respond on the third attempt, a fault alarm is triggered (may be optionally disabled). A summary of pass, fail, and retry counts are maintained in the sensor memory, and may be viewed on the Auto-test History page.

The auto-test generator plugs into the bottom of the sensor holder and is connected to the monirot base. On a timed sequence the Auto-Test generator will test the sensor response to verify that the sensor will still respond to the necessary gas properly.