Ozone use for Post-Harvest Processing of Berries

Ozone can be a valuable tool in the post-harvest processing and storage a variety of edible berries. Ozone can both be used in aqueous form, dissolved into water to wash berries, and also in gaseous form in storage to prolong shelf-life in storage.

The same ozone system can be used to both provide ozone in water and gaseous ozone for storage. Or, based on applications the machine can be built for either application.

Ozone Applications in Berries:

- Washing and disinfection: Ozone can be dissolved into water to be used to clean berries after harvest. The ozone helps in disinfecting the berries by inactivating bacteria, molds, yeasts, and other microorganisms present on their surfaces. This reduces the risk of microbial contamination and extends the shelf life of the berries.

- Surface sanitation: Ozone can be applied as a surface treatment to berries, either through a spray of aqueous ozoneor by exposing them to an ozone-rich environment. This helps in reducing microbial load, including pathogens, on the surface of the berries, enhancing their safety and quality.

- Mold and fungal control: Berries are prone to mold and fungal growth, which can lead to spoilage and reduce shelf life. Ozone treatment inhibits the growth of molds and fungi, reducing the chances of decay and extending the freshness of the berries.

- Pesticide degradation: Ozone can be used to degrade and remove pesticide residues present on the surface of berries. By breaking down pesticides into harmless byproducts, ozone helps in ensuring the safety of the berries and meeting regulatory standards.

- Ethylene removal: Ethylene gas is naturally produced by fruits and can accelerate the ripening process. Ozone can be used to remove ethylene from the storage environment, slowing down the ripening of berries and extending their shelf life.

- Oxidation of organic matter: Ozone oxidizes organic compounds present on the surface of berries, such as sugars and organic acids. This oxidation process helps in reducing the substrate available for microbial growth, further enhancing the safety and quality of the berries.

How it Works:

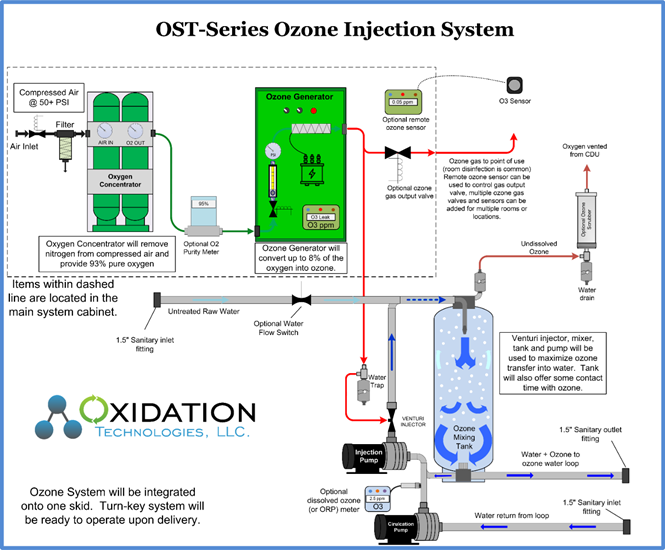

Ozone is generated from oxygen in the ambient air we breathe. That oxygen is captured with the ozone system in the oxygen concentrator and converted to ozone (O3) via corona discharge (high intensity spark). This ozone /oxygen gas can be dissolved into water to use on berries, or used as a gas in storage. The diagram below provides an example of a turnkey ozone system skid and how it functions.

Below are examples of this system in real-life. This is what an ozone skid looks like from the outside:

|

|

| OST-30 Ozone Water System | Rear view of OST-30 |

Aqueous Ozone:

Ozone can be dissolved into water to wash/rinse berries at any stage of post-harvest processing to provide anti-microbial intervention. Below is an example of ozone water spraying on cranberries directly after harvest. The berries are wet from the cranberry bogs and are washed/rinsed with aqueous ozone prior to the drying, and sorting process before storage.

Gasseous Ozone:

Ozone is generated as a gas from oxygen. This ozone gas can be introduced into the storage facility where berries and other produce are stored. Ozone gas is added to existing ventilation at very low and controlled levels. Ambient ozone detectors are used to measure ozone levels in the room and control ozone levels to safe levels for both people and the specific produce in storage.

Ozone gas will slow spoilage of berries by reducing bacteria and mold levels in the air and the rate at which these pathogens can increase. Ozone will also reduce ethylene levels in the air by oxidizing ethylene directly. This will slow the ripening, and therefore spoilage rate of the berries.

Ozone GRAS Approval:

Ozone was granted GRAS (Generally Regarded as Safe) by the USDA and FDA due to a petition filed by the EPRI (Energy Partners Research Institute) in an effort to gain more widespread use of ozone in food processing as an effort to reduce energy consumption. Both the original petition and the final handbook assembled by the EPRI are available in the links below. Additional information on ozone regulations can be found HERE.

Due to GRAS approval granted for the use of ozone the implementation of ozone is allowable for all food applications in the USA with minimal additional regulation.

Ozone in Organic Food Production:

Ozone is allowed for use in the organic production of food products. The National Organic Program (NOP) has allowed for the use of ozone to varying degrees in various applications. For more information on the use of ozone in organic food production follow this link.

Potential Water Savings:

Ozone has been implemented in various applications to lower water consumption or waste along with reclaiming water for re-use in a food plant.

Closed-loop water systems can benefit from ozone use as ozone will oxidize organics in water while leaving no or minimal by-products when compared to other chemical options. By keeping water disinfected while maintaining clearer, cleaner, odor free, and chemical by-product free water system change-outs can be minimized saving water and saving processing time.

Ozone can be used to reclaim water from processes by offering disinfection, color removal, and odor removal from that water for use in secondary applications within the plant.

It is important to note that ozone should be used within the appropriate concentration and contact time to ensure effective microbial inactivation while avoiding any negative impact on the berries' quality. Proper ozone management systems, including monitoring and control, should be implemented to ensure safe and efficient ozone application in the postharvest processing of berries.

By employing ozone in these ways during postharvest processing, the shelf life of berries can be extended, reducing spoilage and waste, while also improving food safety by minimizing microbial contamination.

References and Case Studies:

Below are references and specific case studies of the use of ozone in post-harvest processing of varies berries. Initially are summaries, with references and links to specific white papers below.

Review of the Applications of Ozone For Increasing Storage Times of Perishable Foods

Full paper attached for review.

Cranberries - Early Black and Howes varieties of cranberries 36 and 144 days in ozone-containing atmospheres. At concentrations of ozone which were effective in controlling fungus rot (0.60 ppm), the ozone-treated Early Black cranberries lost more weight during storage at 60°F than did the controls. With Howes cranberries, weight loss of the ozone-stored berries was three times that of the controls, and the quality of the berries was destroyed by the second or third week. In addition, after storage in ozone-containing atmospheres, the cranberries developed a faint, flower-like aroma, not unpleasant, but definitely not present in the control samples.

These authors concluded that ozone at 60°F reacts with the protective cranberry cuticle, thus rupturing the coating and allowing fungus rot organisms to enter the berries. This caused them to spoil faster and lose weight at a much faster rate than the controls. However, the authors recommended that further studies should be conducted using storage temperatures of 40°F and lower to determine if ozone would be more effective and less detrimental at lower temperatures. Ozone concentrations of 0.27 ppm had no effect at 60°F.

Other Berries - Early work of Ewell (1950) showed that 2 to 3 ppm of ozone applied continuously or for a few hours per day doubled the storage lives of strawberries, raspberries, currents and sweet wine grapes, all of which are susceptible to mildew growths. With strawberries, an increase in aroma was noted upon ozone treatment. However, the packing of the exposed fruit has to be loose enough so as not to hinder access of the ozone-containing atmosphere to the fruit being stored.

Berger & Hansen (1965) stored two varieties of strawberries at 15°C in atmospheres containing ozone concentrations between 4 and 350 mg/m3. The maximum concentration of ozone which extended the storage life of strawberries without causing damage to the fruit was 20 mg/m3.

Quality Effect of Ozone Treatment for the Red Raspberries Storage

Gasseous ozone was used in storage to prolong the life of rasberries. Ozone levels used were 50, 200, and 500 ppb. Quality of fruit was evaluated after ozone storage for up to 15 days. Acceptable fruit quality was maintained with the highest quality found in the samples treated with 50-20 ppb ozone.

Impact of Ozonation Process on the Microbiological Contamination and Antioxidant Capacity of Highbush Blueberry (Vaccinum corymbosum L.) Fruit during Cold Storage:

Gasseous ozone at fairly high levels of 15-30 ppm were used in storage of blueberries. Both bacteria and fungi levels were reduced in ozone treated samples vs control samples with no negative effects to the fruit.

Role of Ozone Concentrations and Exposure Times in Extending Shelf Life of Strawberry:

Gasseous ozone was used to prolong shelf-life of straberries. Low levels of ozone (0.075, 0.15 ppm) prolonged shelf-life with no negative affect to the strawberry.

Ozone Storage Effects on Anthocyanin Content and Fungal Growth in Blackberries:

Ozone gas was used in storage at levels of 0.1 and 0.3 ppm. Blackberries stored in the presence of ozone showed lower fungal development and less decay than control while retaining better color in the ozone treated samples

Decontamination of Escherichia coli O157:H7 and Salmonella enterica on Blueberries Using Ozone and Pulsed UV-Light:

Ozone gas and aqueous ozone were used to reduce E.coli O157:H7 and Salmenella. Ozone in water achieved complete elimination of both E.coli O157:57 and Salmonella, while gasseous ozone achieved a 3.0 and 2.2 log reduction respectively. No noticeable change to the quality of the fruit was noticed with either treatment.

Effeect of Ozone Treatment and Controlled Atmosphere Storage on Quality and Phytomchemicals in Highbrush Blueberries:

Highbush blueberries (Vaccinium corymbosum L.) are highly perishable and marketed soon after harvest. To extend the marketing season, CA storage is used to slow deterioration and maintain quality. Ozone (O3) is a strong antimicrobial agent and may be an alternative antifungal agent for the fruit industry. Ozone may also induce antioxidants in treated fruits or vegetables. The combination of CA storage and ozone may create new opportunities for the blueberry industry. ‘Coville’ blueberries were treated with ozone at concentrations of 0, 200, or 700 ppb for 1, 2, or 4 days. Samples were evaluated immediately, or after storage at 10 °C for 7 days in air, or at

0 °C for 4 weeks in CA (10 kPa CO2/15 kPa O2). The percent marketable fruit was 4 to 7 % greater with treatments of ozone for 2 or 4 days in combination with CA than in controls. Respiration was stimulated immediately after treatment with 200 ppb O3 for 1 or 2 days but no differences were found in RQ and ethylene production. Volatile profiles were affected by ozone. Antioxidant capacity, phytochemicals such as anthocyanins and phenolic compounds were not induced by treatments with ozone.

Author: Authors: J. Song, L. Fan, C.F. Forney, M.A. Jordan, P.D. Hildebrand, W. Kalt, D.A.J. Ryan

Link: HERE

Quality Effect of Ozone Treatment for the Red Raspberries Storage:

The improvement of the storage solutions and the infrastructure is a significant opportunity to the management of the post - harvest fruit losses and the maintenance of the quality in the supply chain. The environmental issue and the sustainability of the applied processes are the key of the succesful for the innovation of the food system; the sanification of the storage environment could represent a good opportunity to achieve this objective. The focus of this work was to evaluate the efficacy of the ozone (O 3 ) such environmental sanitization system to limit both the quantitative and the qualitative losses of the raspberry fruits. Fruits exposed to the O 3 constant concentration of 500 ppb (S1) and to the O 3 concentration between 200 and 50 ppb (S2) were compared with fruits maintained in the normal atmosphere (control). The efficacy of the S1 and

S2 treatments were evaluated measuring along the storage time the fruits weight losses (%), the total soluble solids content (SSC), the pulp firmness, the acidity content, the skin colour and the most important nutraceutical compounds. The fruits were stored at 1±1°C in a cold room held at 90–95% RH for 3, 6, 9 and 13 days. After each time at low temperature the same berries were held in shelf life for different additional days (respectively +6, +3, +9 and +2) at 20±1°C to simulate retailer conditions. All the qualitative and nutraceutical traits were maintained to the exposure of O 3 . Fruits stored with the S2 treatment showed the highest sensorial profile.

Authors: Nicole Roberta Giuggioli*, Rossella Briano, Vincenzo Girgenti, Cristiana Peano

Source: DISAFA, Università degli Studi di Torino, Largo Braccini 2, Grugliasco (TO) 10095, Italy

[email protected]

Impact of Ozonation Process on the Microbiological Contamination and Antioxidant Capacity of Highbush Blueberry (Vaccinum corymbosum L.) Fruit during Cold Storage:

In the studies conducted, the impact of the innovative ozonation procedure on the microbial state and antioxidant potential of highbush blueberry (VaccinumcorymbosumL.) stored under cold storage conditions was assessed. Microbiological analysis was carried out to determine the total number of mesophilic aerobic bacteria and the total number of fungi during the storage experiment. In addition, changes in the flavonoid, anthocyanins, and vitamin C content and the total antioxidant capacity were monitored during the storage. The degree of fruit infection with gray mold and anthracnose was determined. It was found that daily ozonation of fruits with a dose of 15 ppmfor 30min, every 12 h, for 28 days effectively reduced the development of aerobic mesophilic bacteria and fungi. On the last day of storage, symptoms of the infection by gray mold were observed in 27.5% of the control fruit, while the absence of symptoms was observed in case of the ozonated fruit. On the other hand, ozone was ineffective in case of inhibiting the infection by anthracnose. Nevertheless, the ozonation process allowed maintaining a high antioxidant potential of the fruit and substantially reduced losses of flavonoids, anthocyanins, and vitamin C. The utilized procedure has proved to be effective, providing the possibility of extensive use of ozone as a factor allowing sustaining a high commercial and consumption value of the fruit over extended time.

Authors: Tomasz Piechowiak, Piotr Antos, Radosław Józefczyk, Patryk Kosowski, Karol Skrobacz, and Maciej Balawejder - Department of Chemistry and Food Toxicology, Faculty of Biology and Agriculture, University of Rzeszów, 35-601 Rzeszów, Poland

Link: HERE

Role of Ozone Concentrations and Exposure Times in Extending Shelf Life of Strawberry:

Efficiency of three aqueous ozone concentrations (0.075 ppm, 0.15 ppm, 0.25 ppm) and two exposure times (2 and 5 min) were investigated for maintaining strawberry quality. Exposure to 0.075 ppm and 0.15 ppm ozone delayed the changes in pH, total soluble solids, firmness and electrical conductivity. All ozone treatments prevented mold growth during storage. However, the 0.25 ppm ozone treatment caused loss of strawberry quality due to high ozone concentration. The results have shown that; low (0.075 ppm) and middle (0.15 ppm) ozone concentrations can be applied to extend the shelf-life of strawberries by at least 3 weeks under refrigerated conditions.

Authors: Mehmet Seçkin Aday, Mehmet Burak Büyükcan, Riza Temizkan, and Cengiz Caner - Department of Food Engineering, Engineering-Architecture Faculty, Çanakkale Onsekiz Mart University, 017020 Canakkale, Turkey - Department of Agricultural Machinery, Çanakkale Onsekiz Mart University, 017020 Canakkale, Turkey

Link: HERE

Decontamination of Escherichia coli O157:H7 and Salmonella enterica on Blueberries Using Ozone and Pulsed UV-Light:

Efficacy of gaseous ozone, aqueous ozone, and pulsed UV-light was evaluated for the purpose of decontaminating blueberries artificially contaminated with either Escherichia coli O157:H7 or Salmonella. Blueberries were exposed to 4 different gaseous ozone treatments: continuous ozone exposure, pressurized ozone exposure, and 2 combined treatments. Maximum reductions of Salmonella and E. coli O157:H7 after 64-min pressurized or 64-min continuous exposure were 3.0 and 2.2 log10 CFU/g, respectively. Aqueous ozone experiments were conducted at 20 °C and 4 °C and zero plate counts were observed for E. coli O157:H7 and Salmonella after 64 min of ozone exposure at 20 °C. Finally, pulsed UV-light was evaluated at 3 different distances from the light. Maximum reductions of 4.3 and 2.9 log10 CFU/g were observed at 8 cm from the light after 60 s of treatment for Salmonella and E. coli O157:H7, respectively. A sensory analysis as well as color analysis was performed on blueberries from each treatment agent; neither analysis detected a difference between treated and untreated blueberries. The results presented in this study indicate that ozone and pulsed UV-light are good candidates for decontamination of blueberries.

Authors: K.L. Bialka, A. Demirci

Link: HERE

Ozone Storage Effects on Anthocyanin Content and Fungal Growth in Blackberries:

Ozone exposure was assessed for storage of thornless blackberries which are prone to fungal decay. Blackberries were harvested and stored for 12 days at 2°C in 0.0, 0.1, and 0.3 ppm ozone. Berries were evaluated for fungal decay, anthocyanins, color and peroxidase (POD) activity. Ozone storage suppressed fungal development for 12 days, while 20% of control fruits showed decay. The main mold was Botrytis cinerea. Ozone storage did not cause observable injury or defects. By 12 days, anthocyanin content of juice was similar to initial levels for all treatments. Surface color was better retained in 0.1 and 0.3 ppm-stored berries by 5 days and in 0.3 ppm berries by 12 days, by hue angle values. POD was greater in controls and 0.1 ppm samples, and was lowest in 0.3 ppm fruits by 12 days. Ozone storage resulted in market quality extension.

Authors: M. MARGARET BARTH, CEN ZHOU, JULIEN MERCIER, FREDERICK A. PAYNE

Link: HERE