Beef (Red Meat) Processing with Ozone

Food safety and shelf life of beef (red meat) can benefit from the proper implementation of ozone in aqueous and/or gaseous form. Ozone is effective at eliminating the most common food-borne microorganisms causing spoilage and illness. There is a great deal of research and real-world applications of ozone use for the inactivation of Escherichia coli, Listeria monocytogenes, along with other common pathogens.

Ozone can be dissolved into the water creating a versatile and safe aqueous solution that can be sprayed directly on carcasses, on meat cuts during further processing, or used to sanitize processing equipment. Ozone is generated as a gas and can be used in the gaseous form directly. In the gaseous form, ozone can be used in storage environments, eliminate airborne contaminants, as a surface sanitized where water and other cleaners can't reach, and be used for odor control.

The use of ozone in red meat processing offers some of the following benefits.

- Excellent antimicrobial ability - ozone has the highest oxidation potential, bacteria cannot create immunity to ozone

- Lack or chemical residuals - ozone reverts safely to oxygen

- No chemical storage - ozone is generated on-site, no dangerous chemicals to handle

- Lower chemical costs - ozone is generated on-site, only electrical power is used for production

- Synergistic benefits - ozone can be used with other antimicrobial interventions to offer an excellent synergy

- Improved indoor air quality - ozone destroys microorganisms safely in the air preventing cross-contamination from airborne pathogens

GRAS Status:

Ozone has been granted GRAS (Generally Regarded as Safe) approval by the FDA and USDA. Having GRAS status means the use of ozone can be implemented with no regulation on the levels of ozone used and allows the use of ozone in various methods within the processing systems provided good manufacturing procedures are in place. Ozone has also been approved for use in many other countries for food processing.

Organic Red Meat Processing:

Ozone has been approved for use in red meat processing by the National Organic Program (NOP) in various applications. Ozone can be used for surface sanitation as a sanitizer within 100% organic foods. Ozone can be used as a sanitizer on the meat itself (direct contact) and maintain an Organic rating. More info on organic food production can be found HERE.

Aqueous Ozone:

Ozone can be dissolved in water to form an aqueous ozone solution. This is commonly referred to as Ozonated Water. This aqueous ozone solution must be prepared on-site as ozone is is consumed and implemented due to the short half-life of ozone, ozone will quickly revert to oxygen. The level of ozone in water is important and must be sufficient for antimicrobial interventions required for the specific application. There is not one-size-fits-all solution in the application of ozone in red meat processing. Below is a broad overview of the use of aqueous ozone in this application. Should you have questions or need assistance, please do not hesitate to contact our office.

Ozone levels in water:

Using the proper ozone levels in water is vitally important. Too little ozone in water will do little more than washing with clean water. Too high of ozone levels in water may off-gas into the ambient air causing a human safety concern in the facility.

We suggest ozone levels in water of 2.0 ppm or greater. Ozone levels up to 5.0 ppm can normally be used with minimal off-gassing from the water. Water containing ozone should be sprayed on the meat gently without a harsh spray or a misting spray. Water pressures of 10 - 30 PSI are generally used with great success and minimal ozone off-gassing.

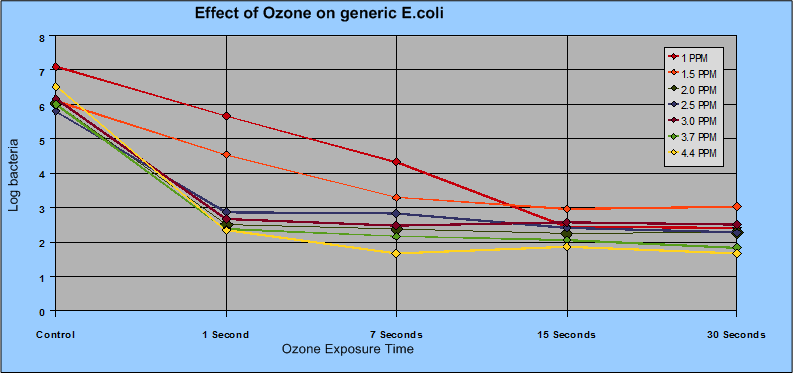

Work we have done has shown that levels of ozone below 2.0 ppm can be effective at bacteria elimination but with longer contact times. While ozone levels above 2.0 ppm have minimally increased benefits. See chart below and paper reference HERE for more details on this work.

This chart above, and the paper referenced show that ozone levels greater than 2.0 ppm offer minimal additional benefits in antimicrobial interventions. It is our recommendation to have ozone levels leaving the ozone machine above 2.0 ppm and has high as 5.0 ppm to ensure that the water that touches, and rinses from the meat or surface maintains the target dissolved ozone level of 2.0 ppm.

Spraying aqueous ozone - contact with surfaces:

Water is used as the carrier of ozone in these applications. This water must come into direct and sufficient contact with any surface requiring disinfection. This might be the meat itself, processing surfaces, machines, knives and other equipment. Spray nozzles should spray water gently without a harsh or misting spray at water pressures from 10-30 PS to ensure minimal off-gassing of ozone from the water. Contact time with water on the surface should be greater than 1-second. On a conveyer system use spray nozzles with a round or square pattern to allow for spraying on the meat surface for a 3-second period of time, or use multiple spray nozzles. See some images below for details.

|

| Aqueous ozone is sprayed on beef brisket as it moves on a conveyer. Set-up properly this will allow for sufficient contact time between ozone water and beef. Ozone water will also sanitize the conveyer and ensure no transfer of pathogens between beef trimmings. |

Aqueous ozone must provide full coverage of the meat. In a carcass spray this may be simple and easily implemented in existing chiller water, or carcass wash water. In further processing, this may be more challenging. The application below provide a novel, yet simple method of achieving full contact with ozone water on all parts of the beef trimming to be treated with ozone water.

|

|

|

| Beef brisket on conveyer gets sprayed with aqueous ozone | As beef brisket transitions from one conveyer to the next it flips sides due to design | The second side of beef brisket is sprayed with aqueous ozone |

Note: Aqueous ozone solutions will decay to oxygen in water over time. Therefore, a spray application or washing of some type is critical. Water baths with aqueous ozone cannot be used in most applications as ozone in water will be consumed by the initial produce dipped into the water, or even the first half of the meat products will be exposed to ozone in water while the second half will see no ozone as the ozone has reacted with organics successfully and left only clean water.

Also, sufficient water volumes are required to ensure proper ozone levels are successfully used on products to be sanitized.

Gaseous ozone applications:

Ozone is produced as a gas from oxygen in the air. This ozone gas can be diluted into air and used directly in the gaseous state as an antimicrobial agent. This will allow for a greater shelf-life of the meat and lower overall bacterial loads. However, greater care and engineering of the system is required vs aqueous ozone. Experiences and case studies are listed below for examples of this application, however, there is not a one-size-fits-all solution. Should you desire more info on how to use this in your application, please contact our office.

The use of ozone at low levels can extend shelf-life of beef and maintain bacteria free environments, while higher levels that are unsafe for humans can potentially reduce bacterial counts. Ozone can be used in storage, chiller, or within a properly designed ozozne tunnel. Specific ozone levels and potential applications are outlined in some of the referenced documents below.

Ground Beef applications:

Ozone can be used as an antimicrobial intervention in ground beef. We have worked with customers using ozone in ground beef applications using two different methods.

Ozone gas can be used to treat ground beef in a mixer.

Ozone can be dissolved in water at high levels and added to the ground beef to make up shrink weight during other processing. In this application high dissolved ozone levels are required.

Ozone Regulations in Food Processing

Ozone regulations in Organic food production

Resolution Concerning the Use of Ozone in Food Processing from original EPRI documents

Original EPRI Direct Food Additive Petition used to gain GRAS approval for ozone

Ozone used for Ecoli O157:H7 Inactivation

Ozone used for Listeria monocytogenes Inactivation

A Novel Aqueous Ozone Treatment as a Spray Chill Intervention Against Escherichia Coli O157:H7 on Surfaces of Fresh Beef

Authors: NORASAK KALCHAYANAND; DREW WORLIE; TOMMY WHEELER

Abstract

This experiment determined the efficacy of using a novel aqueous ozone treatment as a spray chill intervention to reduce Escherichia coli O157:H7 on surfaces of fresh beef compared with traditional water spray chill. Cutaneous trunci muscles were obtained from a local beef cattle processing plant. Muscles were divided into sixteen 25-cm2 sections, and each section was individually inoculated with E. coli O157:H7 to the final concentration of approximately 105 CFU/cm2. Muscle sections were collected and tested before and after simulated spray chill treatments of water or the novel aqueous ozone solution. Enumeration of survivors of each treatment was compared with that of the untreated muscle sections. Water spray chill reduced (P ≤ 0.05) E. coli O157:H7 0.60 log, whereas the aqueous ozone spray chill reduction (P ≤ 0.05) was 1.46 log on surfaces of fresh beef. Aqueous ozone spray chill reduced (P ≤ 0.05) aerobic bacteria 0.99 log, but water spray chill did not significantly (P > 0.05) reduce aerobic bacteria on surfaces of fresh beef. The findings indicate that aqueous ozone can be used as a spray chill intervention to enhance the safety of beef.

HIGHLIGHTS:

- Aqueous ozone spray chill could be an effective antimicrobial intervention.

- Nanobubble technology may enhance the efficacy of ozone application.

- These results need to be validated under commercial conditions.

Mitigation Strategies for Salmonelle, E. Coli O157:H7 and Antimicrobial Resistance Throughout the Beef Producation Chain

Author: Casas Murillo, Diego Eduardo 0000-0002-7897-9904

Abstract

According to the World Bank, foodborne illness costs over $110 billion per year in low- and middle-income countries. In the United States, Salmonella and big 7 Shiga toxin-producing E. coli (STEC) account for 26% of economic burden of foodborne illness. Meat and poultry are attributed approximately 38% and 27% of Salmonella and E. coli O157:H7 foodborne illnesses respectively. Consequently, the beef industry has diligently developed and researched different antimicrobial mitigation strategies that will reduce the concentration and prevalence of Salmonella and E. coli O157:H7, as well as antibiotic resistance development throughout the beef production chain. In our first study, the objective was to determine the effect of dietary L28 and tylosin on Salmonella, Enterococci, generic E. coli, and E. coli O157 presence in fecal grabs, perineal and hide swabs, and subiliac lymph node samples and their antimicrobial susceptibility profile. Generic E. coli and Enterococci presence were high throughout the feeding trial, 98.3% and 96.1% respectively. Salmonella presence was substantially high (62.7%) within pens and similar among treatments. No effects (P > 0.152) among treatment on microbial presence were observed in any of the four microorganisms studied within the pen and perineal samples. However, Salmonella presence within lymph nodes was affected by the treatments (P < 0.001). The MONPRO treatment (34.8%, 26/46) had a greater presence of Salmonella than the MONTY (8.7%, 4/46) and the PRO treatment (0.0%, 0/42). The presence of Salmonella, Enterococci, generic E. coli, and O157 did not increase with supplementation of L28 compared to the control. All Salmonella isolated was susceptible to every antibiotic class evaluated except one isolated with ample resistance to β-lactams. No significant difference (P > 0.05) between treatments was observed in the overall phenotypic resistance of Salmonella, E. coli, and Enterococci. Moreover, a tendency in the increase of overall resistance was observed across treatments as the days of feed increased. The absence of Salmonella in L28 treatment lymph nodes suggests supplementation of L28 may contribute to mitigating Salmonella’s capacity to invade the lymphatic system. This poses a significant contribution to the beef industry as lymph nodes can be a substantial source of Salmonella in ground beef. In the second study the objective was to conduct a longitudinal field study to probe the impact of the soil properties and weather on Salmonella survival and persistence in the feedlot ecosystem. Subsequently leading to the identification of factors that can be used as pre-harvest mitigation strategies. Salmonella prevalence varied throughout the seasons (P < 0.01), where the highest prevalence was observed in summer and fall seasons. A difference in prevalence between feedlots was observed (P <0.01), Feedlot 4 had the highest prevalence with an average of 57.2% (151/264) in all the year. In comparison, Feedlot 3 had a 17.4% (46/264) average prevalence in the year. Surface pen samples had a higher presence of Salmonella than deeper soil stratum sampled. Soil nutrient profile exploratory analysis showed a significant predictor effect in Salmonella presence, suggesting potassium, phosphorus, and calcium concentration in soil were positively correlated with Salmonella presence, whereas copper and magnesium were negatively correlated with Salmonella presence. Further research will elucidate the effect specific nutrients in the soil have on Salmonella presence and persistence. Moreover, seasonal variation of Salmonella presence can lead to tailored interventions at different stages of the year based on the possible risk of Salmonella entrance into the beef processing environment and have a risk-based approach to Salmonella mitigation to further ensure food safety. In the third study, the objective was to evaluate the antimicrobial efficacy of an aqueous ozone (Bio-Safe) treatment and lactic acid solutions on natural microbiota and E. coli O157:H7 and Salmonella surrogates on beef carcasses and trim in a commercial beef processing plant. Ozone and lactic acid interventions significantly reduced (p < 0.003) bacterial counts in carcasses and trim samples. Moreover, lactic acid further reduced APC and coliforms in trim samples compared to ozone intervention (p < 0.009). In the surrogate trials, ozone significantly reduced (p < 0.001) surrogate concentration. Historical data from the plant revealed a reduction (p < 0.001) of presumptive E. coli O157:H7 in trim after a full year of ozone intervention implementation. The novel technology for ozone generation and application as an antimicrobial can become an alternative option that may also act synergistically with existing interventions, minimizing the risk of pathogens such as Salmonella and E. coli O157:H7. In the fourth study, the objective was to determine the impact of spray and dry chilling combined with hot water carcass treatments on the levels of microbial indicator organisms during the long-term refrigerated storage of beef cuts. Not enough evidence (p > 0.05) was found indicating the hot water wash intervention reduced bacterial concentration on the carcass surface. E. coli was below detection limits (< 0.25 CFU/cm2) in most of the samples taken. No significant difference (p > 0.05) was found between coliform counts throughout the sampling dates. Feed type did not seem to influence the (P > 0.25) microbial load of the treatments. Even though no immediate effect was seen when comparing spray or dry chilling of the samples at day 0, as the product aged, a significantly lower (p < 0.05) concentration of aerobic and psychrotrophic organisms in dry-chilled samples could be observed when compared to their spray-chilled counterparts. Data collected can be used to select alternative chilling systems to maximize shelf life in vacuum packaged beef kept over prolonged storage periods.

Antimicrobial Action and Effect on Beef Quality Attributes of a Gaseous Ozone Treatment at Refrigeration Temperature

Authors: N.Zaritzky

Abstract

The effects of gaseous ozone treatment at refrigeration temperatures, on microbial counts (total aerobic mesophilic heterotrophic microorganisms and inoculated Escherichia coli) in culture media and in beef samples were analyzed. The influence of ozone on beef quality properties such as surface color and rancidity was measured.

The effect of gaseous ozone (154 × 10−6 kg m−3) in culture media inoculated with E. coli after 3- or 24-h treatment at 0° and 4 °C caused a total inactivation of this microorganism.

For beef samples treated with the same gaseous ozone concentration, the highest microbial inhibition was observed at 0 °C and after 24-h exposure, producing a decrease of 0.7 and 2.0 log10 cycles in E. coli and total aerobic mesophilic heterotrophic microorganism counts respectively; however, both the surface color and lipid oxidation of these beef samples were unacceptable. Shorter exposure times (3 h) to the tested ozone concentration at both temperatures (0–4 °C), reduced 0.5 log10 cycles the counts of total aerobic mesophilic heterotrophic microorganisms and 0.6–1.0 log10 cycles the counts of E. coli, without changing the color or producing rancidity in beef.

Introduction:

The food industry explores innovative technologies in order to meet consumer demand for fresh safe products. Attention is presently focused on ozone since it is a powerful sanitizer that can be applied in the food industry; it is approved by the regulatory agencies and accepted by consumers (Khadre, Yousef, & Kim, 2001). As a strong oxidant, ozone has proven to be an effective bactericide; it also inactivates viruses, fungi and mycotoxins without leaving any toxic by-products or residues. Due to these features, ozone was commercially used as early as the 19th century for the deodorization of industrial waste and disinfecting of drinking water (Uradziński, Wysok, Bielicki, & Gomółka–Pawlicka, 2005).

The bactericidal effect of ozone depends on several factors, such as temperature, relative humidity, pH and the presence of organic matter (Kim, Yousef, & Chism, 1999). In 1997, the Food and Drug Administration (FDA) considered ozone a Generally Recognized as Safe (GRAS) substance in different food applications, which has increased its use worldwide (Kim et al., 1999). Ozone in air is effective in killing Escherichia coli O157:H7 (Reagan et al., 1996). Restaino, Erampton, and Hemphill (1995) found that among the pathogens studied (Salmonella typhimurium, Yersinia enterocolitica and Staphylococcus aureus); Listeria monocytogenes was the most sensitive to ozone. In August 2000, the Food and Drug Administration (FDA) approved ozone as a direct additive for the treatment, storage and processing of foods, in gas or in aqueous phase (Khadre et al., 2001).

One of the most important factors in the efficacy of the ozone application is the treatment temperature since it affects the solubility, stability and reactivity of gas. As the temperature increases, reaction rate also increases but ozone becomes less soluble and less stable. Therefore as the treatment temperature increases, the increase in ozone reactivity is negated by the decrease in its stability, without causing significant changes in the efficacy of ozone (Khadre et al., 2001).

A diversity of results has been reported in the scientific literature, depending on the different ozone concentrations used as well as on their forms of application. Rasanayagam (2006) studied the effect of gaseous ozone concentrations higher than 10,000 ppm (2.14 × 10−2 kg O3 m−3) in beef and poultry inoculated with Salmonella. In these conditions, ozone reduced the population of Salmonella by 99%. Da Silva, Gibbs, and Kirby (1998) studied the efficacy of gaseous ozone in five species of fish bacteria, finding efficacy in concentrations of 270 × 10−6 kg O3 m−3; besides, fresh fish daily treated with that gaseous ozone showed a better sensory aspect over the untreated one.

Oxidative reactions are implicated in functional, sensory, and nutritional quality deterioration in meat and meat products (Morrissey et al., 1998, Ventanas et al., 2006). High concentrations of oxidation catalysts (such as iron and myoglobin) and unsaturated lipids present in muscle tissue predispose muscle foods to oxidative reactions during processing and storage (Decker et al., 1993, Xiong, 2000). The use of ozone in beef can be effective for reducing microbial growth; however, its effects on color and rancidity must also be analyzed. Considering that ozonation requires specific equipment, the treatment performance on the decrease of the microbial counts and also on meat quality attributes must be analyzed, in order to justify the equipment investment.

The objectives of the present work were:

- - To evaluate the effect of gaseous ozone treatment (different exposure times at refrigeration temperatures) on microbial counts of i) total heterotrophic microorganisms and ii) inoculated E. coli, both in culture media and in beef samples as compared to untreated samples.

- - To analyze the influence of ozone on quality attributes of beef tissue (surface color and development of rancidity).

- - To compare the results obtained by using different ozone treatment times (3 and 24 h) and temperatures (0 and 4 °C) in order to select the operating conditions that lead to a better quality of the beef tissue.

Section snippets

Materials and methods:

Different experiments were performed by applying gaseous ozone on different systems: (a) Petri dishes containing culture medium inoculated with one strain of E. coli previously isolated from meat; (b) Non-inoculated beef samples to analyze the effect of ozone on total heterotrophic microbial counts; and (c) Beef samples inoculated with the same E. coli strain as described in experiment (a). Quality attributes of beef samples were also tested to analyze the effect of ozone on oxidative rancidity

Mathematical modeling of the ozone concentration in the continuous ozonation chamber:

The ozone treatment was carried out in a continuous system in which ozone was circulated. In the first stage of the experiment, the composition of the gaseous atmosphere inside the chamber changed, because air was partially replaced by ozone until an asymptotic ozone concentration was reached. In order to determine the time necessary for the ozone concentration in the treatment chamber to reach this asymptotic concentration, a non-stationary mass balance was solved. The mass balance

Conclusions:

Gaseous ozone (154 × 10−6 kg m−3) applied in culture media inoculated with E. coli caused a total inactivation of this microorganism after 3 or 24-h treatment at 0° and 4 °C.

The ozone antimicrobial action was less effective in the case of beef tissue than in culture media because part of the ozone reacts with the tissue components.

For both treatments (3 and 24 h), the microbial reduction was higher when working at 0 °C due to the higher solubility of ozone gas in the aqueous phase of the tissue.

Effect of Pretreatment with Carbon Monoxide and Ozone on the Quality of Vacuum Packaged Beef Meats

Authors: Xin Ma, FeiLyu, KejingShen, YutingDing

Abstract

Beef meats without pretreatment (CK) or pretreated with different volume ratios of carbon monoxide and ozone of 100%CO (T1), 2%O3 + 98%CO (T2), 5%O3 + 95%CO (T3) and 10%O3 + 90%CO (T4) using modified atmosphere packages for 1.5 h, after that they were vacuum-packaged and stored in 0 °C refrigerator for 46 days. The surface color a* values and sensory scores of T1, T2, T3 and T4 were significant higher than CK (p < 0.05) during storage. In the mid and later storage, the drip loss, total viable counts (TVC), metmyoglobin (met-Mb), thiobarbituric acid reactive substances (TBARS), total volatile basic nitrogen (TVB-N) and pH of T1, T2, T3 and T4 were significantly lower than CK (p < 0.05), and these values of T2, T3 and T4 were significantly lower than T1 in the later storage. In conclusion, O3 in the combination didn't affect the color-developing effect of CO, and could help CO maintain the meat quality. Therefore, the pretreatment of CO combined with O3 at certain concentrations can be a promising technique to maintain the quality of beef meats.

Introduction:

Beef meats, one of the most popular consumption meats in the world, are low fat and high protein content, have the nutritional composition of key nutrients, such as minerals, fatty acids and vitamins (Hambidge & Krebs, 2007), and are a major source of high quality dietary proteins for human metabolic processes. However, due to its biological composition, beef represents a favorable environment for microbial growth and is highly susceptible to spoilage (Udenigwe & Howard, 2013). A few preservation technologies have been applied to maintain its safety and quality, and extend the shelf life, which will be useful for both regional farmers and consumers around the world (Aymerich, Picouet, & Monfort, 2008).

Packaging beef meat protects it against deterioration. Vacuum package (VP) lacking of O2 in packages can minimize the oxidative deteriorative reactions. Modified atmosphere package (MAP) consists in the replacement of air in the packaging atmosphere by a mixture of different gases (mainly composed of O2, CO2 and N2), can be used to extend the shelf life of meat (Chaix et al., 2015, Nair et al., 2015). Polyvinyl chloride film (PVC), which is used for retail storage of meat and is extremely permeable to oxygen, and so on. However, for at least two decades, low O2 MAP has been lesser used, on account of VP is the most cost-effective package (Brewer, Jensen, Prestat, Zhu, & McKeith, 2002).

A recent research indicated that color and appearance are the most frequently used factors in consumer purchase decisions and judging shelf life of fresh meat (Brewer, Wu, Field, & Ray, 1994). As we all know, enzyme-mediated reactions termed metmyoglobin-reducing activity always dissipates making the color of meat terrible during storage (Kropf, 2003), but carbon monoxide (CO) can displace O2 from oxymyoglobin (MbO2), once it has been bound and carboxymyoglobin (COMb) is more stable than deoxymyoglobin (Elbadawi, Anglemei, Cain, & Samuels, 1964). In order to impart a desired red color, meat may be exposed to CO before sealing or in low CO atmosphere (CO-MAP) be sold out. Nevertheless, Cornforth and Hunt (2008) reported that there were two major disadvantages of CO-MAP. As the potentially hazardous gas, CO might bring negative images to the consumers. In this way, the pretreatment of CO for meat may be more suitable than CO-MAP for consumers. Another is the color of meat also looks fresh, even though the bacterial levels of beef are high. Therefore, meat preservation techniques should be developed to control the risk of microbial contamination.

Sometimes, the main cause of fresh meat spoilage is the growth of bacteria, and increasing bacteria will modify the color and quality of the meat (Renerre, 1990). We know that ozone (O3) is highly reactive and a strong oxidizing agent, in the meantime, classified as “GRAS” (Generally Recognized as Safe) by the United States Environmental Protection Agency (USEPA). People all over the world have used O3 to kill bacteria, sanitize drinking water and food, and decrease aflatoxin contamination (Inan, Pala, & Doymaz, 2007). Moreover, Kim and Yousef listed a number of bacteria species that are commonly found on food and are very susceptible to O3 (Kim & Yousef, 2000). It means that in some cases, O3 can have better sterilization ability than the other gas. Several studies revealed O3 exposure prevents microbial growth and extends the shelf life of treated produce. Dondo, Nachtman, Doglione, Rosso, and Genetti (1992) found that the O3 treatment can greatly inhibit the amount of microbes of fishes, and improve the effect of its sensory quality. Treatment with O3 water resulted in about 1.25 (log CFU/g) reductions of total bacteria of Pacific oyster before storage respectively, and enhanced the shelf life of 2 days (Rong, Qi, Yin, & Zhu, 2010). Furthermore, other studies showed that half-life of gaseous O3 is 12 h at atmospheric pressure, and gaseous O3 is more stable than aqueous O3 (Weavers & Wickramanayake, 2001).

The color-stabilizing effect of CO and the sterilization effect of O3 have been reported previously. However, limited information is available on the effects of co-treatment of CO and O3 on quality of beef stored, no published results from experiments combining both technologies are available. Thus the objectives for this study were to investigate the effect of the combination gases of CO and O3 pretreatment on the microbiological, chemical, physical and sensory characteristics of beef meats during storage at 0 °C and to find the best way to extend the shelf life and maintain good qualities for vacuum packaging beef meats.

Raw materials:

A total of 8 Luxi × Simmental steer (18–24 months old, 286–323 kg) were selected randomly from a local farm, and slaughtered on a commercial abattoir. The longissimus lumborum and psoas major of the tenderloin were removed from both sides of the carcasses after 48 h post-mortem, and were trimmed of all visible fat and cut into beefsteaks about 50 g with 2 cm thickness.

O3 was produced from O3 generator (QD-OS-S-300L, Guangzhou, China). CO was supplied by Hangzhou Distribution Company (Hangzhou, China)

Carbon monoxide penetration:

We tested the effect of different volume ratios of CO and O3 pretreatments on the quality of beef meats and the CO penetration. CO penetration depth of all samples treated with CO (T1, T2, T3 and T4) increased remarkably from about 10 mm at the beginning to about 18 mm on day 4th from the top to bottom sides (Fig. 2), and then the penetration rate decreases. CO pretreatment alone (T1) showed earlier and faster infiltration situation significantly compared with T2, T3 and T4 on day 0 and 2 (p <

Conclusion:

In order to maintain the fresh beef meat quality, the combination of CO and O3 was pretreated to beefsteaks in this study. Although the CO penetration depth of the 100% CO pretreatment T1 was higher than the combination pretreatments with O3 and CO (T2, T3 and T4) at the beginning, all CO pretreatments nearly arrived at the same depth in the end. Furthermore, compared with the untreated group (CK), the pretreated groups with CO (T1, T2, T3 and T4) displayed higher a* and b* values and lower

Link to full paper can be found HERE

Microbial, Instrumental Color and Sensor Color and Odor Characteristics of Ground Beef Produced From Beef Trimmings Treated with Ozone or Chlorine Dioxide

Authors: M.R Stivarius, F.W Pohlman, K.S McElyea, J.K Apple

Abstract

The effects of beef trimming decontamination with ozone and chlorine dioxide on ground beef microbial, color and odor characteristics were studied. Beef trimmings were inoculated with Escherichia coli (EC) and Salmonella Typhimurium (ST), then treated with either 1% ozonated water for 7 min (7O) or 15 min (15O), or with 200 ppm chlorine dioxide (CLO) and compared with a control (C). Trimmings were ground, packaged and sampled at 0, 1, 2, 3 and 7 days of display for EC, ST, coliforms (CO), aerobic plate counts (APC), instrumental color, as well as sensory color and odor characteristics. The 15O and CLO treatments reduced (P<0.05) all bacterial types evaluated, whereas the 7O treatment reduced (P<0.05) APC and ST. All treatments caused ground beef to become lighter (L*) in color (P<0.05); however, the 15O treatment was similar (P>0.05) in redness (a*), percentage discoloration, beef odor and off odor intensities when compared to C.

Introduction:

After chilling, fabrication of beef carcasses can result in product contamination. Carcass contamination not removed by trimming or washing at slaughter is spread to newly exposed surfaces, which in turn can potentially decrease the shelf life of retail cuts and ground beef in retail meat display cases (Emswiler, Kotula, & Rough, 1976). Johnson, Titus, McCaskill, and Acton (1979) theorized that carcass washing treatments would reduce total bacteria counts on carcasses and in ground beef prepared from such carcasses. Dickson and Anderson (1992) and Siragusa (1995) have reviewed the practice of using antimicrobial interventions to reduce the microbial load on beef carcasses. Both agree that the use of decontamination steps can play an integral part in reducing pathogens inoculated onto carcasses during slaughter. Due to the possibility of product microbial contamination through normal processing, researchers (Dorsa et al., 1998, Ellerbracht et al., 1999) have begun to evaluate the effect of using antimicrobial treatments in the production of ground beef, and the effects on microbial control. If successful, an additional decontamination step before grinding would allow for an added measure of safety by reducing microbial numbers on beef trimmings, which may become contaminated through processing before the production of ground beef.

Powerful oxidants such as ozone and chlorine dioxide have been used as potential antimicrobial treatments to decontaminate beef tissues (Kochevar et al., 1997, Reagan et al., 1996). The method of action for oxidants is to cause irreversible damage to the fatty acids in the cell membrane and to cellular proteins of the microorganisms (Luck & Jager, 1998). Emswiler et al. (1976) reduced aerobic plate counts by 1.64 log colony forming units (CFU)/cm2 using 200 ppm chlorine on beef carcass tissues. Similarly, Unda, Molins, and Zamojcin (1989) found that 100 ppm chlorine dioxide reduced aerobic mesophilic bacteria by 1 log CFU/cm2 on fresh beef steaks but had a negative affect on the redness of color. Kochevar et al. (1997) reported a reduction in aerobic plate count (APC) of 2.64 log CFU/cm2 using 35 °C water in combination with 0.003% chlorine dioxide on lamb adipose tissues. Likewise, Gorman, Sofos, Morgan, Schmidt, and Smith (1995) used a combination of 35 °C water and 0.5% ozone to reduce Escherichia coli on beef brisket fat by 1.84 log CFU/cm2. Gorman, Morgan, Sofos, and Smith (1995) achieved an APC reduction of 1.49 log CFU/cm2 using 35 °C water and 0.5% ozone on beef adipose tissue. In addition, Reagan et al. showed that using 2.3 ppm of ozone on beef carcasses reduced APC by 1.3 log CFU/cm2.

Although the use of oxidants has received attention for reducing microorganisms on muscle surfaces and adipose tissue, it is unclear what effect these antimicrobials might have when used in a ground beef production system. Furthermore, few researchers have evaluated the impact of oxidant antimicrobial treatments on instrumental color or sensory characteristics of beef tissues. Therefore, the objective of this study was to determine the effects of ozone or chorine dioxide treatment of beef trimmings before grinding on the reduction of pathogens and other microorganisms, as well as instrumental and sensory color and odor characteristics of ground beef.

Bacterial preparation and inoculation:

Inoculums were prepared from frozen (−80 °C) stock cultures of E. coli (ATCC #11775) and a nalidixic acid resistant strain of Salmonella Typhimurium (ATCC #1769NR). E. coli was maintained by brain heart infusion (BHI)(Difco Laboratories, Detroit, MI, USA) broth with glycerol (20%) and Salmonella Typhimurium was maintained by BHI broth containing nalidixic acid (86 mmol; Fisher Scientific, Fairlawn, NJ, USA) with glycerol (20%). Frozen cultures of E. coli and Salmonella Typhimurium were thawed,

Antimicrobial treatment effects on microbial populations, instrumental color and sensory color and odor characteristics

Chlorine dioxide (CLO) was effective (P<0.05) against all bacterial types evaluated (Table 1). Chlorine dioxide reduced E. coli (EC), coliforms (CO), Salmonella Typhimirium (ST) and aerobic plate count (APC) 0.71, 0.57, 0.61 and 0.72 log CFU/g, respectively, in ground beef compared to the control (C). These results are in agreement with Emswiler et al. (1976) which concluded that 200 ppm chlorine sprayed on beef carcasses was effective for reducing APC by 1.64 log CFU/cm2. Similarly, Unda et

Conclusion

The use of chlorine dioxide or ozone in ground beef production systems can be effective for reducing microbial pathogens with minimal effects on color or odor characteristics. Additional work might focus on concentration and exposure times necessary to optimize antimicrobial properties....

Treatment of beef with gaseous ozone: Physicochemical aspects and antimicrobial effects on heterotrophic microflora and listeria monocytogenes:

Authors: Belen Gimenez, Natalia Graiver, Leda Giannuzzi, Noemi Zarizky

Centro de Investigación y Desarrollo en Criotecnología de Alimentos (CIDCA), CONICET, Fac. de Cs Exactas, UNLP. 47 y 116, La Plata, 1900, Argentina

Depto. de Ing. Química, Fac. de Ingeniería, UNLP. 47 y 1, La Plata, 1900, Argentina

Received 12 May 2020, Revised 1 September 2020, Accepted 2 September 2020, Available online 4 September 2020, Version of Record 13 September 2020.

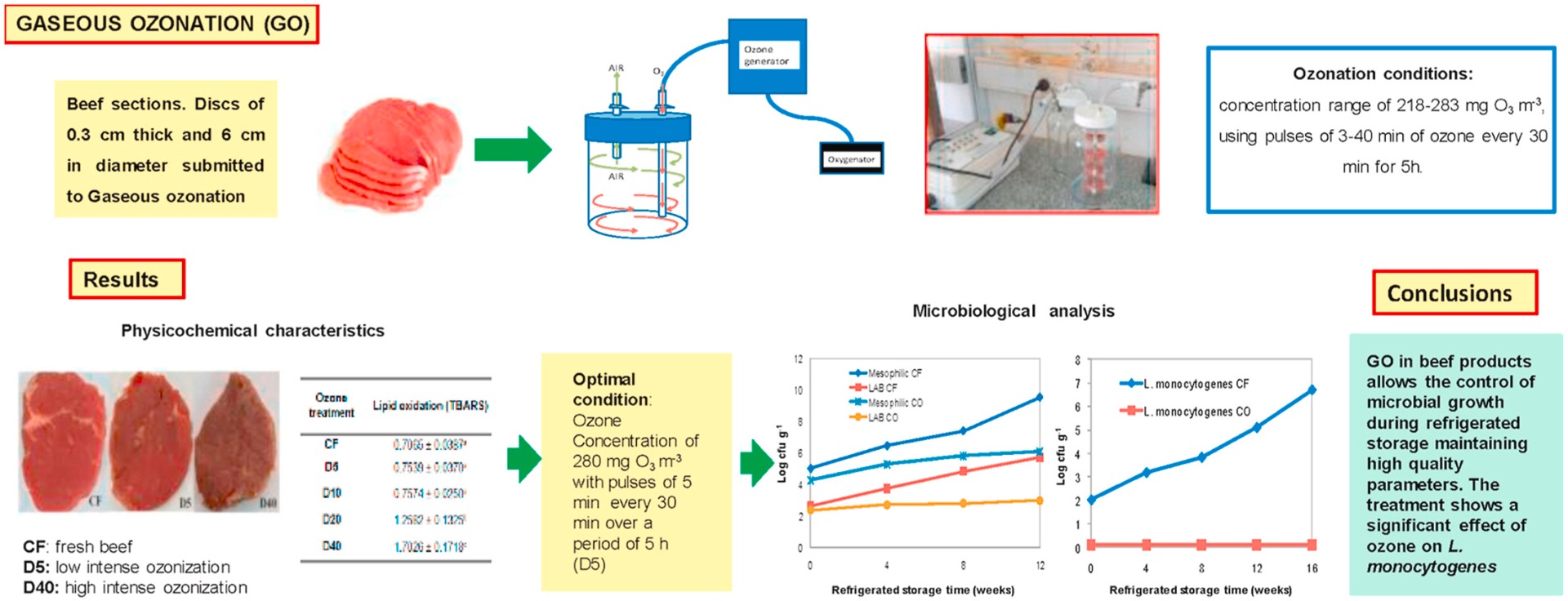

The treatment of beef with gaseous ozone (GO) was analyzed and the physicochemical characteristics (texture, lipid oxidation, surface color) and food safety (microbial growth of heterotrophic microflora and inoculated Listeria monocytogenes) were evaluated.

Transient changes in ozone concentration within the chamber were mathematically modeled using a non-stationary mass balance. Ozone pulses were applied and treatment intensities were evaluated in each case. GO treatment prolonged refrigerated storage of vacuum packed beef. Long periods of exposure to ozone (>10 min) negatively affected the red color and oxidative rancidity. The most effective treatments to control microbial flora were ozone pulses ranging between 5 and 10 min duration every 30 min for 5 h using 280 mg O3 m−3; these treatments allowed the reduction of more than 1 logarithmic cycle the counts of the natural flora in beef (lactic acid bacteria, mesophilic and enterobacteriaceae), maintaining oxidative stability and adequate physicochemical parameters. Additionally these low doses of GO decreased the counts of inoculated L. monocytogenes (102 CFU g tissue−1) to values below the detection limit for 16 days at 4 °C limiting its growth during refrigerated storage. The use of GO in beef products allows the control of microbial growth during refrigerated storage maintaining high quality parameters.

Graphical abstract:

Introduction:

In recent years, different emerging technologies for food preservation have been introduced due to the undesirable consequences caused by the thermal treatments (pasteurization, blanching and sterilization) on many products, such as the decrease in the nutritional value and physical changes of the food. Among the non-thermal technologies that are applied to maintain the safety and quality of food products, the main studied procedures are: radiofrequency, gaseous ozone, high hydrostatic pressure (HHP), high intensity pulsed electric fields, ultrasound, etc.

Ozone is a potent disinfecting agent and a strong oxidant. The application of gaseous ozone (GO) currently has several advantages; excess of ozone auto-decomposes rapidly to produce oxygen and thus leaves no residues in foods from its decomposition (Akata, Torlak, & Erci, 2015). It has stronger antimicrobial activity than chlorine and is considered a broad-spectrum antimicrobial agent that acts against a variety of foodborne pathogens (Priyanka, Rastogi, & Tiwari, 2014). Gaseous ozone molecules have longer half-life and higher diffusion than the ozone molecules in aqueous state (Kim, Yousef, & Dave, 1999). Usually, the threshold limit of ozone exposure calculated as 8 h/day, is considered to be 0.1 ppm (0.2 mg m−3). Increasing exposure and concentration of ozone can result in health problems. Exposure to ozone at 0.1–1.0 ppm can cause dry throat, irritation to the respiratory system, headaches and smarting eyes. Symptoms resulting from exposure to concentrations between 1 and 100 ppm may be similar to asthma, such as tiredness and loss of appetite. Exposure at high concentrations for short periods of time can cause throat irritation, hemorrhage and pulmonary congestion (Pascual, Llorca, & Canut, 2007).

Ozonation treatment has long been used in different countries. The bactericidal effect of ozone on a wide range of microorganisms has been tested, including Gram positive and Gram negative bacteria, as well as their spores and vegetative cells, fungi, and even it has shown a capacity to be a virucidal agent (Sheng et al., 2018). In 1997 the U.S. Food and Drug Administration (FDA) recognized ozone as GRAS (Generally Recognized As Safe) for its use in contact with food (Kim et al., 1999), and in 2001 gave its final ruling, approving the regulations for the use of ozone as a food additive, during processing or storage (O'Donnell, Tiwari, Cullen, & Rice, 2012, pp. 1–312).

Ozone has multiple applications in the food industry including water treatment and disinfection of equipment as well as for the preservation of perishable foods such as fruits, vegetables and meat products (Guzel-Seydim, Bever, & Greene, 2004; Lyu, Shen, Yuting, & Ma, 2016). Gaseous ozone has advantages over aqueous ozone due to its penetration capacity, which allows it to reach the most inaccessible places in products where pathogens are found (Shynkaryk, Pyatkovskyy, Mohamed, Yousef, & Sastry, 2015). However the oxidizing action of ozone can damage the quality of red meats by increasing rancidity and modifying surface color. Ozone can easily oxidize muscle tissues, producing undesirable discolorations and leading to rancid flavors in fatty tissues (Clark & Takacs, 1980; Kaess & Weidemann, 1968).

Listeriosis, whose etiologic agent is Listeria monocytogenes, is one of the main foodborne diseases and of great relevance to public health, due to the social and economic impact it has and the severity of its clinical picture (Muñoz, Vargas, Otero, Díaz, & Guzmán, 2011). The gastroenteritis, meningitis, and septicemia have reported as the main clinical manifestation. L. monocytogenes is a ubiquitous microorganism that survives a long time in food, and it is a major concern for the agri-food industry. It has demonstrated a high capacity to resist different processing conditions, such as high and low temperatures, modified atmosphere and processing environments, its presence indicates a possible contamination during food processing and post-processing (Magalhães et al., 2016). Bacteria belonging to the genus Listeria are short Gram-positive, facultative anaerobic, non-sporulating, which are usually observed individually or in short chains, motile via flagella at 30 °C and below, but usually not at 37 °C (Gründling, Burrack, Bouwer & Higgins, 2004). L. monocytogenes can move within eukaryotic cells by polymerization of actin filaments. The optimum growth temperature is between 30 and 37 °C; it is a psychotrophic pathogen, capable of growing at refrigeration temperatures (0–8 °C). It is also capable of developing at a pH of 4.4–9.6; it grows at high concentrations of NaCl (10%) and survives at concentrations between 16 and 20% (Muñoz et al., 2011).

L. monocytogenes alone is globally responsible for more than 20,000 sicknesses and 5000 deaths per year and its inactivation is extremely important for ensuring microbiologically safe food products.

Criteria or recommendations for tolerable levels of L. monocytogenes in processed foods have been established in some countries. Food safety regulations in the European Union set a maximum of 100 CFU g−1 L. monocytogenes for ready to eat products during their shelf life (Commission Regulation, 2005), while the criterium in USA is “zero tolerance” that is, not to found organisms in 25 g of a food product (Shank, Elliot, Wachsmuth, & Losikoff, 1996; USDA-FSIS, 2014).

Therefore it is interesting to analyze the inactivation of L. monocytogenes by using non thermal methods such as ozonation. Ozone is used in a wide variety of agricultural products, such as vegetables, fruits and also in fish. Bahrami, Baboli, Schimmel, Williams, and Jafari (2020) have reviewed the efficiency of mild processing technologies, including ozonation to inactivate L. monocytogenes in food products. Coll Cardenas, Andrés, Giannuzzi & Zaritzky (2011) reported the effect of gaseous ozone (154 × 106 kg m3) at refrigeration temperatures, on total aerobic mesophilic heterotrophic microorganisms and inoculated Escherichia coli in culture media. Muthukumar and Muthuchamy (2013) observed that fresh chicken samples inoculated with L. monocytogenes and subjected to a gaseous ozone flow of 33 mg/min for 9 min, showed a significant decrease of L. monocytogenes counts. However, only a limited number of studies have reported the effect of GO on meat products (Coll Cárdenas, Andrés, Giannuzzi, & Zaritzky, 2011; Youngjae, Muhlisin, Tae-Wook, & Sung, 2014). Research on the effect of ozone on red meats and specifically on Listeria monocytogenes in beef is scarce in literature (Kaess & Weidemann, 1968; Youngjae et al., 2014).

The general objective of this work was to evaluate the effect of gaseous ozone on the physicochemical characteristics of beef and on the safety of the process. The specific objectives were: a) mathematical modeling of the transient concentration changes of ozone in the ozonation chamber based on mass balance equations; b) to quantify ozone treatment intensity considering the number of applied pulses and their duration for industrial application; c) to evaluate the quality parameters such as surface color, texture, lipid oxidation, and microbial growth (natural heterotrophic flora and L. monocytogenes inoculated) after the application of the ozone treatment and during refrigerated storage.

Raw materials:

Beef muscles were obtained from the local retail market. The used commercial cut was top inside round; this cut is integrated by the following muscles: adductor femoris and semimembranosus. The average weight of the cuts was about 3.9 kg. 20 cuts from different animals were used in the experiments. The muscles were separated after 48 h post-mortem and all visible fat was trimmed. The raw materials had a pH value between 5.4 and 5.7. Beef samples were obtained in the laboratory under aseptic...

Ozone concentration at the exit of the generator/entrance to the ozonation chamber

The ozone concentration data obtained using the Xilix International electrochemical type meter was verified with the analytical titration technique. The measurements allowed to determine the concentration of ozone (Ce) at the entrance to the ozonation chamber resulting of 283.6 mg O3 m−3 (0.283 mg L−1). Using the ozone density (2.14 kg m−3) the concentration of ozone expressed in volumetric ppm (cm3 O3 m−3 of gas) was also calculated (Ce = 132.52 volumetric ppm)...

Mathematical modeling of transient changes of ozone concentration in the ozonation chamber

In order to quantify ozone...

Conclusions:

In the present work gaseous ozone treatment prolonged refrigerated storage life of beef tissue. The most effective treatments to control microbial flora were the application of 280 mg O3 m−3 with pulses ranging between 5 and 10 min every 30 min for 5 h, because they allowed the reduction of more than 1 logarithmic cycle in the counts of the natural flora in beef, maintaining oxidative stability and adequate physicochemical parameters such as surface color and texture. Additionally, these...

Efficacy of Gaseous Ozone Against Generic E.coli in Ground Beef:

Authors: Joel Leusink, George Kraft

The use of gaseous ozone was evaluated as an antimicrobial intervention against

Escherichia coli (E.coli) in ground beef. This research took place in two parts. Phase 1 initially

inspected for color and appearance change due to ozone gas oxidizing the beef. Phase 2 tested

for antimicrobial action due to the ozone against E.coli bacteria. Ozone treatment to the ground

beef showed no color or flavor change at ozone levels that were effective at reducing E.coli in

the ground beef. Raw, ground beef inoculated with generic E.coli was treated with gaseous

ozone at various levels it was determined that approximately 95.8% of the E.coli in the ground

beef was killed when the ozone concentration approached 200 ppm.