Megatron Ultraviolet Systems

Call For Price

Call For Price

Why Use UV?

Ultraviolet radiation is lethal to virtually all bacteria, viruses, and fungi. This short wave radiation produced by germicidal ultraviolet lamps can quickly destroy these harmful substances and microorganisms in water. Because no chemicals are added, there is no danger of overdosing or contaminating the water through this process. No unwanted tastes or scents are present after purification and the water is ready for use immediately after it leaves the purifier.

To learn more about UV light as a cleaning solution and how it interacts with ozone, click here.

H ow does it work?

ow does it work?

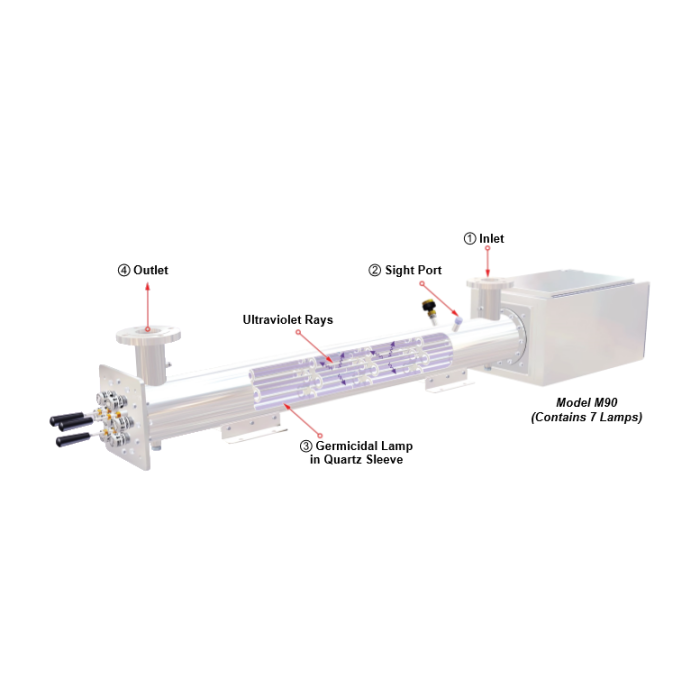

1. Water enters one end of the purifier and flows through the space between the quartz-sleeved germicidal ultraviolet lamp and the chamber wall.

2. A wiper system stirs the water to guarantee that the microorganisms within are evenly exposed to ultraviolet rays.

3. The exits from the other end of the purifier ready for use.

A translucent sight port allows you to verify that the germicidal lamp is operating correctly. When running, its glow will be visible through the port.

Maintenance & Installation

In the event that your Megatron system requires maintenance or the replacement of key components, they are designed to disassemble completely without the use of special tools or fixtures. The end caps are specially designed so that they can be removed by hand and new lamps or sleeves can be installed in a matter of minutes. It is recommended that the lamp be replaced after 10,000 hours of operation (about 14 months of continuous use). A dual-action assembly allows periodic cleaning of the sleeve without the need to disassemble the product or interrupt its operation.

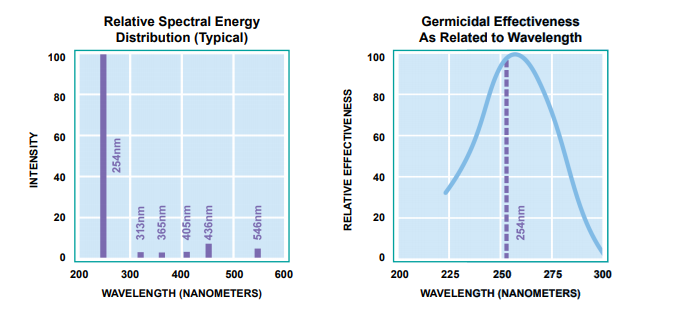

Germicidal Lamp Details

Approximately

Caution: Exposure to direct or reflected germicidal ultraviolet rays will cause painful irritation to the eyes and reddening of the skin. Those who may be subject to this exposure should wear a suitable face shield, gloves, and protective clothing.

Applications

Megatron UV Water purifiers can be used in a wide variety of settings. Here are some examples:

| Institutional | ||

| Laboratories | Labor & Delivery Areas | Universities |

| Hospitals | Pathology Labs | Schools |

| Clinics | Kidney Dialysis Labs | Veterinary Clinics |

| Maternity Areas | Nursing Homes | |

| Transient Systems | ||

| Resorts, Hotels,& Motels | Water Park | Fountain Water Feature |

| Ships, Yachts, Boats | Amusement Parks | Ornamental Ponds |

| Campgrounds | Golf Course Water Holes | Fish Ponds |

| Community | ||

| Apartment Complexes | Villages, Towns, Cities | Fish Farms |

| Condominium Complexes | Farms & Ranches | Mollusk Hatcheries |

| Trailer Parks | Animal Husbandry | Water Preserves |

| Rural Water | Aquariums | Well Water |

| Industry | ||

| Pharmaceutical Mfg. | Water Vending Machines | Edible Oils |

| Electronic Production | Laundry Water | Liquid Sugar |

| Cosmetic Production | Pure Wast Water | Sweeteners |

| Cooling Tower | Bottled Water | Water-Based Lubricants |

| Power Generation | Beer, Wine | Dairy Processing |

| Food Industry | Soft Drinks | Cistern Applications |

| Ice Makers | Fruit Juices | Pulp & Paper Production |

| Bottling Facilities | ||

| Specialized | ||

| TOC Reduction | Ozone Reduction | |

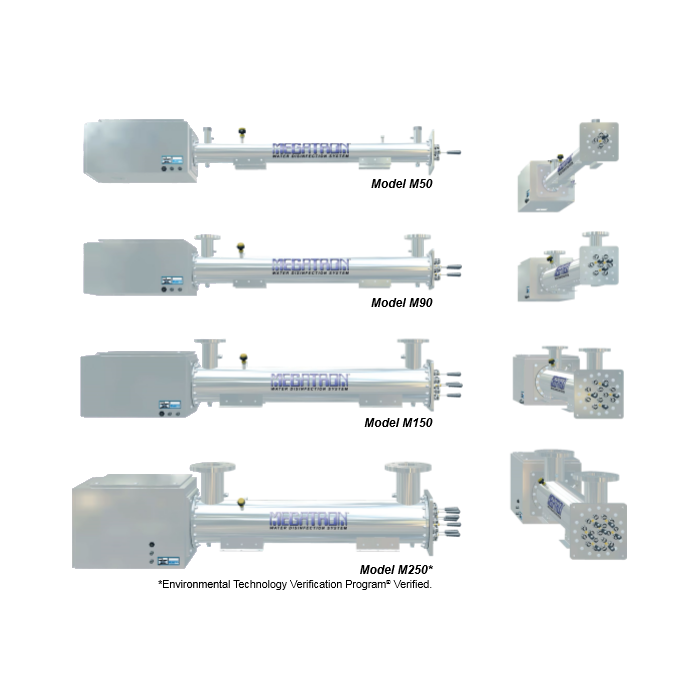

Full List of Megatron Systems

| Model | Voltage | GPM** | Inlet/Outlet | Number of Lamps | Height | Length | Width |

| M50 | 120 | 70-100 | 2" NPT | 4 | 14" | 100" | 16" |

| M90C | 120 | 115-190 | 3" Socket Weld Flange | 7 | 16" | 100" | 16" |

| M150 | 120 | 200-325 | 4" Socket Weld Flange | 12 | 18" | 100" | 18" |

| M250 | 120 | 335-560 | 6" Socket Weld Flange | 19 | 26" | 102" | 21" |

**GPM is determined by water quality

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | No |

| Dimensions (LxWxH) | Dimensions Vary |

| Warranty | 1 Year |

| GPM | 1+ |