OXO-200

OXO-200 Oxygen Generator will produce 150 - 250 SCFH oxygen at 93% purity at 45-55 PSI of pressure.

OXO-200 Oxygen Generator is an industrial oxygen concentrator great for continuous oxygen production. Compressed air must be supplied to the OXO-200. This compressed air is separated via Pressure Swing Absorption (PSA) technology. Oxygen is captured in a storage tank and can be supplied to the point of use at any flow rate required up to 250 SCFH at pressures of 45 - 55 PSI.

Features:

Simple to Operate

The OXO-200 Oxygen Concentrator can be operated in automatic operation allowing for automated operation of the air compressor and oxygen concentrator. The OXO-200 has a built-in pressure switch that will start/stop the oxygen concentrator based on oxygen pressures in the downstream oxygen storage tank.

Using a quality air compressor with an air pressure switch will allow for automated air compressor operation providing for a completely automated system.

No human oversight is required for operation, simply consume oxygen gas as needed, the OXO-200 will start/stop to maintain set oxygen pressure in the oxygen storage tank.

Simple to Install

The OXO-200 Oxygen Concentrator is shipped with an oxygen storage tank that is equipped with all required valves, pressure gauges and tubing. Set-up the OXO-200, connect one tube from the tank to the OXO-200 and supply the OXO-200 with compressed air.

Compressed air is supplied via 3/4" ID Tubing from the compressed air source. Simply connect compressed air from the compressed air tank that is installed in your facility or supplied as a dedicated unit to this system.

No wires or electrical connectors other than the 120 VAC power cord for the OXO-200 is required for operation.

Dependable:

The OXO-200 Oxygen Concentrator is built to provide thousands of hours of continuous, reliable service. The Zeolite sieve is factory sealed in solid steel tanks and rarely needs replacement. With very few moving parts, our oxygen concentrators are built to provide thousands of hours of continuous, reliable service. Routine maintenance consists of filter replacement every few months and rebuilding valves every 16,000 hours of operation. Sieve material will require replacement after 5-10 years depending upon air quality.

Durable

OXO-200 is built with precision-welded tank assemblies (ASME coded) with stainless steel screens to hold sieve material for air separation. Air/oxygen is plumbed through brass, and stainless steel valves for purging an oxygen oxygen capture.

Made in the USA

The OXO-200 Oxygen Concentrator is manufactured by Oxidation Technologies. Tanks and skid are welded and powder coated locally (within 30 miles). All final assembly, and wiring is completed in our factory in Inwood, IA.

Specifications:

| Product Flow | 150 - 250 SCFH |

| Product Pressure | 45-55 PSI |

| Product Concentration | 93% +/- 2% nominal |

| Product Dew Point | -100°F (-73°C) |

| Dimensions (W x D x H) | 26" wide x 26" deep x 72" tall |

| Weight | 750 lbs |

|

Physical Connections Compressed Air Inlet Product Gas Outlet |

1/2" Female NPT 3/8" Femlae NPT |

| Feed Air Requirements |

Flow Rate = Based on O2 flow settings Pressure: 90 psig minimum Temperature: 122°F maximum |

| Power Requirements | 120 VAC 50/60 Hz, 3.0 Amp (220 VAC, and 24 VDC optional) |

Typical Applications:

- Ozone Generator feed-gas

- Wastewater treatment (odor)

- Biogas

- Fish Farming, Aquaculture, and Hydroponics

- Manufacturing: cutting, brazing, soldering, thermal, chemical oxidation

- Glass work, glass blowing

Air-Flow Demand:

| O2 Product Flow | Feed Air Requirement |

| 150 SCFH O2 Flow | 28 CFM Air |

| 175 SCFH O2 Flow | 32 CFM Air |

| 200 SCFH O2 Flow | 37 CFM Air |

| 225 SCFH O2 Flow | 41 CFM Air |

| 250 SCFH O2 Flow | 45 CFM Air |

Installation:

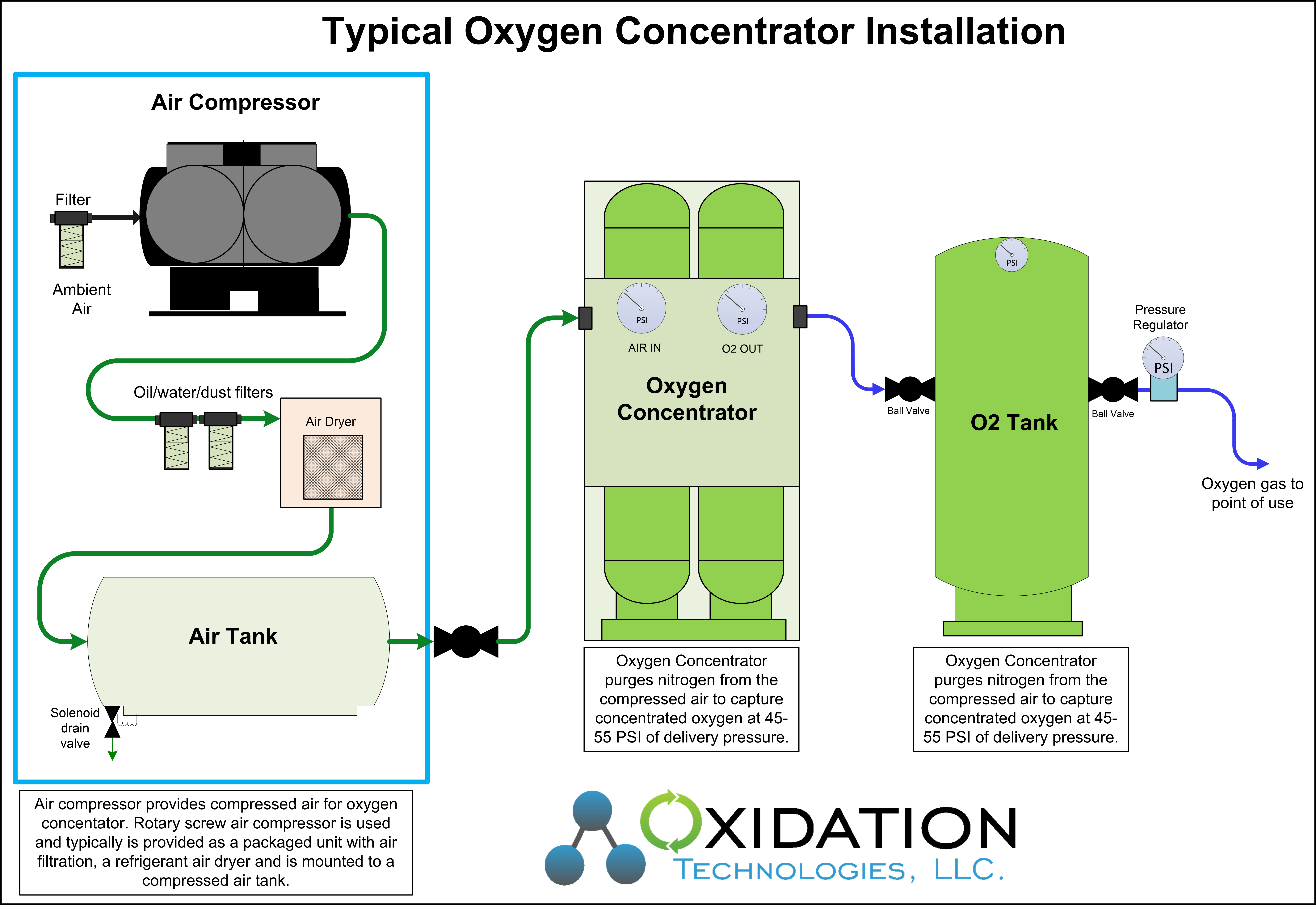

The OXO-200 can be supplied with compressed air that is clean and dry from an on-site source. However, if necessary a dedicated air compressor can be provided to provide compressed air to the OXO-200 oxygen concentrator.

Packaged air compressors are available with integrated air filtration, refrigerant air dryers, all tank mounted to an air receiver tank. These air compressors are automated with pressure switches to operate automatically as compressed air is demanded.

Diagram below shows a common installation of the OXO-200 Oxygen Concentrator.

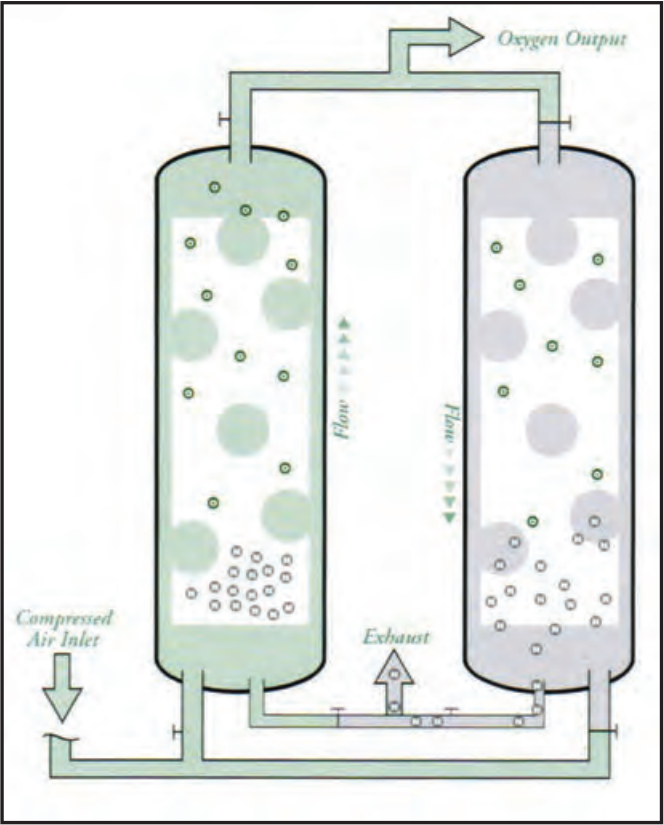

What is Pressure Swing Adsorption (PSA):

Clean, dry compressed air is fed into the first molecular sieve bed. Nitrogen is adsorbed, while oxygen is allowed to flow through. When the sieve in the first bed becomes full of nitrogen, the airflow is then directed into the second bed. As the second bed separates the oxygen from the nitrogen, the first bed vents its nitrogen into the atmosphere. Compressed air is once again fed into the first bed, and the process is repeated continuously. A constant flow of oxygen is reliably produced.

The OXO-200 Oxygen Concentrator requires compressed air for operation. Typical installation of entire system is outlined below:

- Air compressor will provide at least 23 CFM compressed air at 90PSI or greater

- Particulate filter will remove most dust, and oil from air stream

- Refrigerant air dryer is used to remote moisture from air and provide 40-deg F dew point

- Coalescing filter will remove any final oil mist and moisture from air flow

- Air storage tank is necessary to provide sufficient air storage for oxygen generator purging

- Oxygen Generator will purge nitrogen from air and capture oxygen

- Oxygen storage tank will store oxygen and provide consistent oxygen flow and pressure to point of use

- We also suggest installing an oxygen filter downstream of the oxygen storage tank to filter any zeolite dust from the oxygen concentrator

Optional oxygen purity switch can be added to the oxygen concentrator as an alarm. Simple oxygen purity monitoring. Provides relay contacts to alert of potential problems in your oxygen generation system.

Features:

- Powered and wired into oxygen generator

- Oxygen plumbed through unit, no oxygen losses

- Reliable ultrasonic sensor technology

- Dual DPDT relay outputs, alarms triggered at > 85% O2 and > 75% O2 respectively.

- Integrated LCD display

- Relay alarm for low oxygen purity

- Analog or digital output

- Optional remote monitoring

- Optional visual strobe light

- Optional audible alarm

Downloads:

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | Yes |

| Listing Description | 150-250 SCFH @ 45-55 PSI |

| Oxygen Production | 101 - 250 SCFH |

| Internal Compressor | No |

| O2 Delivery PSI | 45+ PSI |

| Nominal Gas Flow Rate | 200 SCFH |

| Operating Pressure | 45-55 PSI |

| Max Pressure | 55 PSI |

| Gas Connections | 3/8" Female NPT |

| Dimensions (LxWxH) | 26" wide x 26" deep x 72" tall |

| Operational RH Range | 0-85% humidity |

| Operational Temperature Range | 35 - 95-deg F |

| Power Requirements | 120 VAC, 60 Hz, 1-phase, 6amp (220 VAC optional) |

| Lead Time | 2-weeks |

| Warranty | 1 Year |

| Country of Origin | USA |

| Description | Requires 37 CFM air @ 90 PSI |