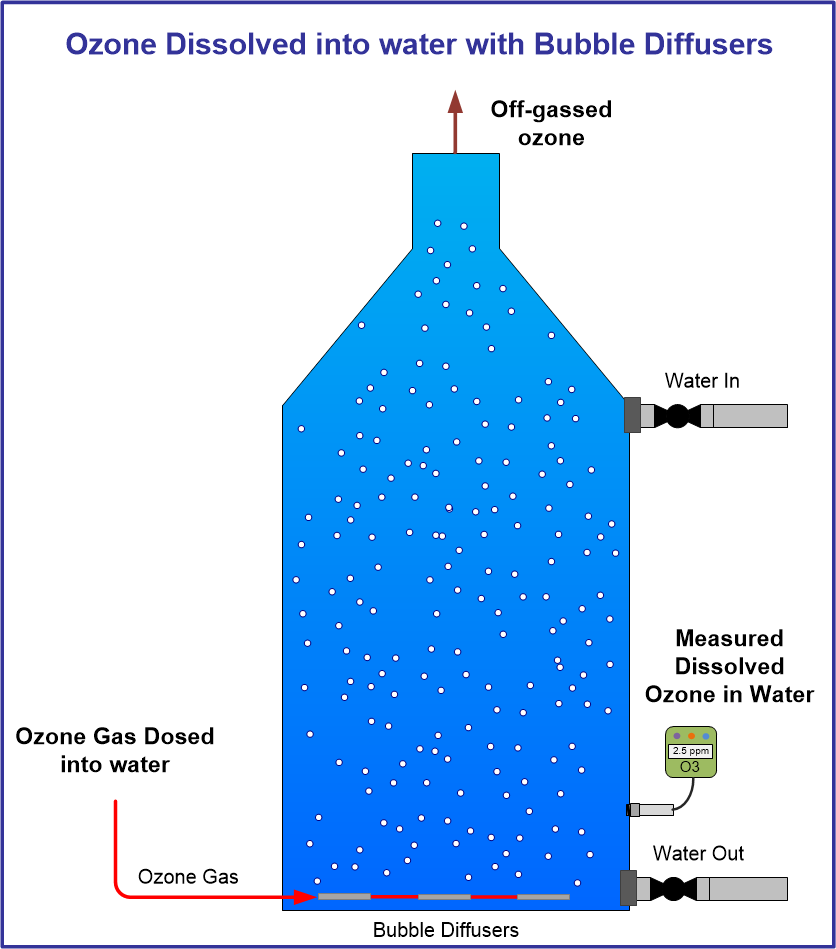

Ozone dissolved with bubble diffusers

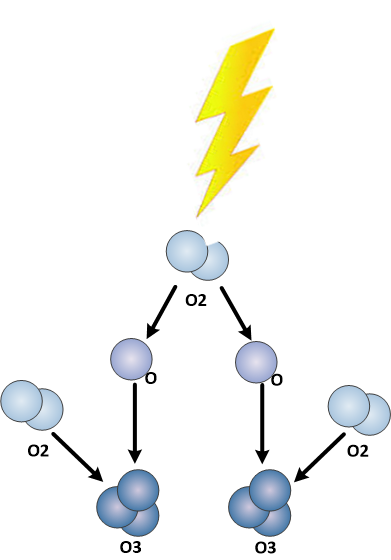

Ozone gas can be dissolved into liquid with simple bubble diffusers, similar to what is commonly used in the bottom of a fish aquarium for aeration. This is a simple and cost-effective method to dissolve ozone gas into liquid. As ozone is partially soluble into liquid the ozone gas will transfer into liquid immediately at the interface between the ozone gas bubble surface and the surrounding water.

|

Diffusers implement a gas permeable membrane that will disperse the gas stream into many smaller ozone gas bubbles in the water. As these ozone gas bubbles naturally rise to the surface of the water that ozone will transfer into the water due to contact between the liquid and gas bubble.

Advantages:

-Low cost

-No moving parts

-Easy to setup

-Low energy – does not require water pumps or elevated water pressures

-Simple, reliable operation long-term

-Generally the least efficient method of dissolving ozone into liquid

-Diffusers can become plugged and may require periodic replacement

-Difficult to use in pressurized water flows

Ozone gas is partially soluble into liquid. However, using proper methods and equipment high mass transfer efficiencies can be realized with any method of dissolving ozone into water. Review the tips below for success using an ozone gas bubble diffuser in your ozone application.

Fundamentals of Ozone Solubility:

-Lower temperatures increase the solubility rate of ozone gas into liquid

-Higher pressures increase the solubility rate of ozone gas into liquid

-Higher ozone gas concentrations increase the solubility rate of ozone gas into liquid

Design considerations for your bubble diffuser and column:

Diffuser Micron Ratings – Smaller Is better!

Ozone gas bubble diffusers will be rated in micron size, or resulting bubble size the diffuser will create. The membrane that splits the gas stream into small bubbles will have pore sizes, smaller pores will result in smaller bubbles. This pore size or bubble size is normally referred to in a micron rating.

Micron = micrometer. Equal to 0.001 millimeter, or about 0.000039 inch

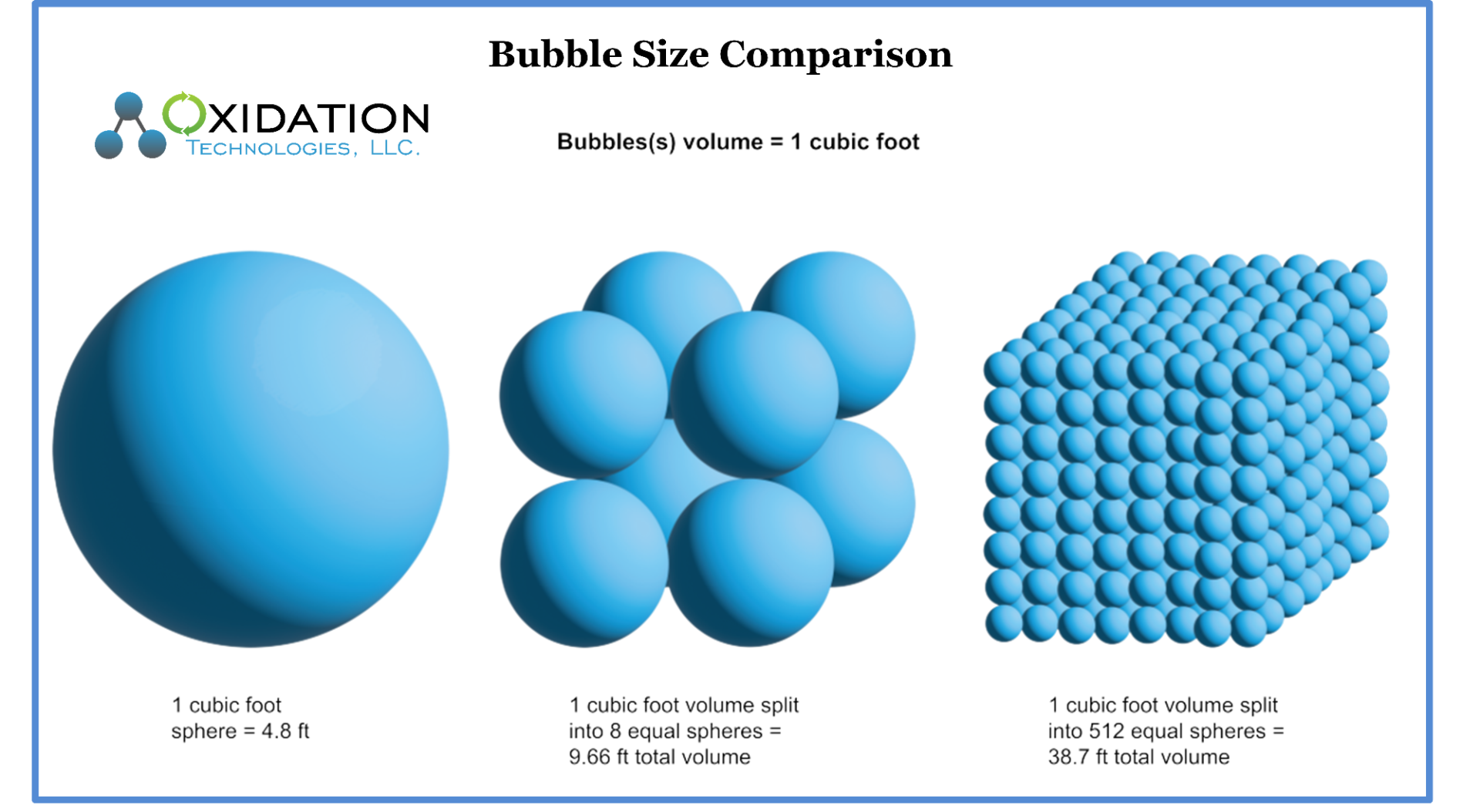

Smaller bubbles create more surface area of the gas the ozone is flowing in. Greater surface area will increase the ability of ozone gas to transfer into the liquid. See the example below:

The image above shows the same gas volume (1 ft3) shown in one bubble, 8 identical bubbles, and 512 (8 tall x 8 wide x 8 deep) identical bubbles.

-

- One 1 cubic foot sphere = 4.8 ft2 surface area

- Eight 0.125 cubic foot spheres = 1 cubic foot = 1.2 ft2 each = 9.66 ft2 total surface area

- Eighty 0.0125 cubic foot spheres = 1 cubic foot = 0.26 ft2 each = 20.8 ft2 total surface area

- 512 0.001953 cubic foot spheres = 1 cubic foot = 0.07567 each = 38.7 ft2 total surface area

A bubble size ¼ the size (4.8 / 4 = 1.2) results in 8x more bubbles and double the overall surface area.

Relating this to your ozone gas flow. A 25 micron diffeser will create bubble sizes ¼ the size of a diffuser rated for 100 micron therefore creating more than 2x the surface area of gas contacting the water at the same flow-rate of gas flowing into water.

Smaller really is better!

Tank Design – Skinny Is Better!

Gas bubbles will naturally rise to the surface of water due to buoyancy. Therefore, the taller your tank, column or ozone tank is the longer your gas bubble will remain in the water increasing the opportunity for the gas to transfer into the liquid.

Taller tanks will also increase the water

pressure at the bottom of the tank where the ozone gas diffuser will likely be placed. Greater water pressure will increase the natural solubility of ozone gas into liquid. For example:

11.33 feet of water = 5 PSI

5 PSI = 34% increase in ozone solubility vs 0 PSI

Increasing your water column by 11.33 feet will increase your solubility of ozone, or your mas potential ppm of ozone in water by 34%.

1 ppm becomes 1.34 ppm with no other changes.

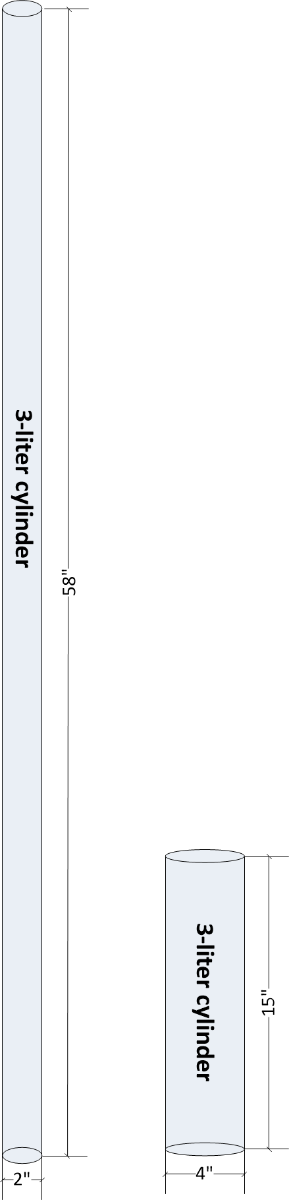

A great example of separate columns is shown in the image and dimensions below. Both columns are 3 liters in volume, with a change in diameter from 2” to 4” the height is increased from 12” to 58”

-

2” diameter x 58” tall = 182 in3 = 3 liters

-

4” diameter x 15” tall = 188 in3 = 3 liters

If you have the opportunity when desiring your tank or reactor, choose the smallest diameter possible.

Skinny really is better!

Counter Current Flow:

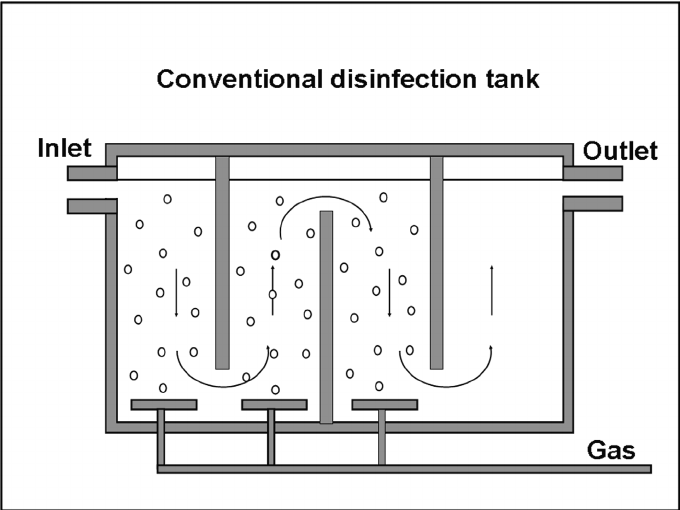

Ozone contacting basins can be designed with counter-current flow, where the water flows counter-current to the gas bubbles. While gas bubbles will naturally rise to the surface of the liquid due to buoyancy liquid can be forced into the path of the gas bubble to create additional turbulence. The diagram below shows a simple contactor basin design using baffles to create counter-current and con-current flows of ozone gas to liquid

This same technique can be applied to any column in flowing water using piping water flowing down a column that ozone gas is rising within. Consider this simple technique when designing your tank or piping system

Diffuser material:

Material compatibility should always be considered when using ozone gas for any application, this is no different. The diffuser is exposed to both gaseous ozone and aqueous ozone consistently, this is the harshest environment for ozone resistant materials.

A few diffuser types are reviewed in brief below:

Stone or Ceramic Diffusers:

Stone and ceramic are the most common and easiest to the source. These are commonly used in fish aquariums and other common applications. These are low cost, easy to obtain and work rather well. They are commonly available in pore sizes from 50 – 100 micron, most commonly in 100-micron sizes.

Advantages:

-Low cost

-Readily available in many configurations

Disadvantages:

-Material compatibility can be an issue. While the ceramic or stone material may hold up to ozone great, the ozone gas connection must be connected to the stone or ceramic material. This connection is made with glue, plastics, or other materials that commonly break-down due to ozone over time

-Fouling can be an issue as the surface is rough. Minerals and contaminates attach to the surface and plug the diffuser over time

-Breakage is possible as the stone or ceramic will degrade or can crack over time

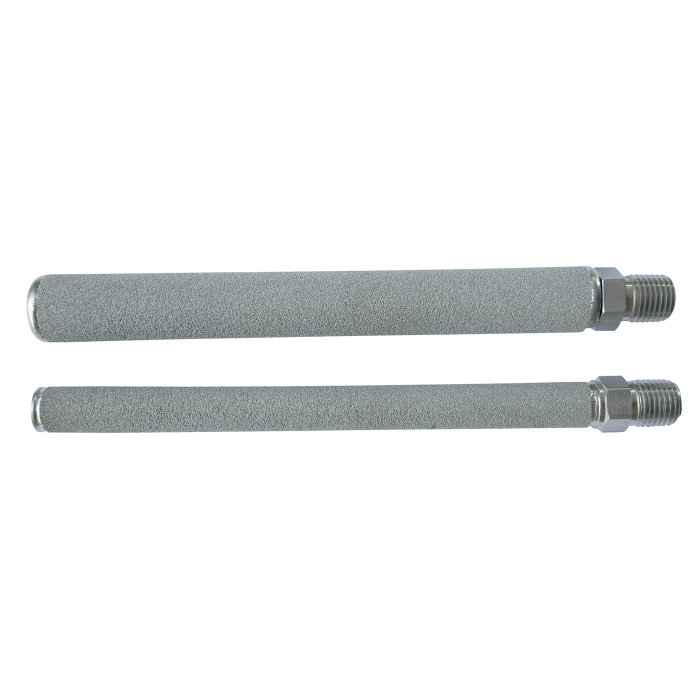

Stainless Steel Diffusers:

Sintered stainless steel can be manufactured in a variety of configurations, sizes and pore sizes. These have become more available over time and can be obtained in a variety of configurations. Pore sizes from 5 – 50 micron are common with these diffusers.

Advantages:

-Great material compatibility due to stainless steel construction and stainless steel welded connections

-Small micron sizes available

-Durable, long-lasting construction will not crack or break easily

Disadvantages:

-Not compatible with acids, or some metals in water such as iron

-Higher cost than ceramic or stone

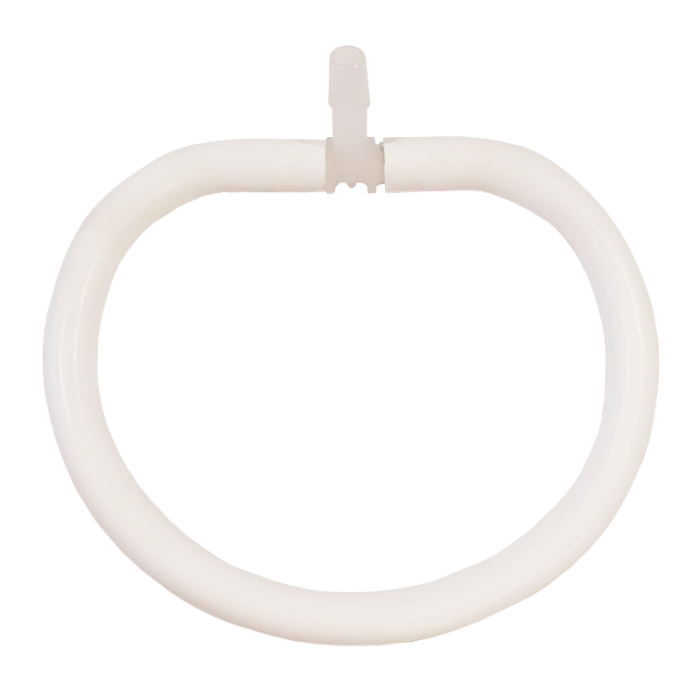

PTFE Diffusers:

PTFE or Teflon diffusers use PTFE tubing or material as a membrane. These are newer in the marketplace and only available in a few configurations from a few suppliers. Tubing is bendable, mold-able and can be used in a variety of configurations. Common micron sizes are 20 – 100 microns.

Advantages:

-Great material compatibility

-Minerals do not readily attach to the PTFE material

-Bendable into many different configurations to fit specific applications

Disadvantages:

-Higher cost

-Limited available options

Additional Information Links:

Ozone Dosage vs Dissolved Ozone

Dissolve Ozone into water with Bubble Diffuser

Dissolve Ozone into water with Venturi Injector

Dissolve ozone into water with Static Mixer

Compare Venturi Injector and Bubble Diffusers