Cannabis

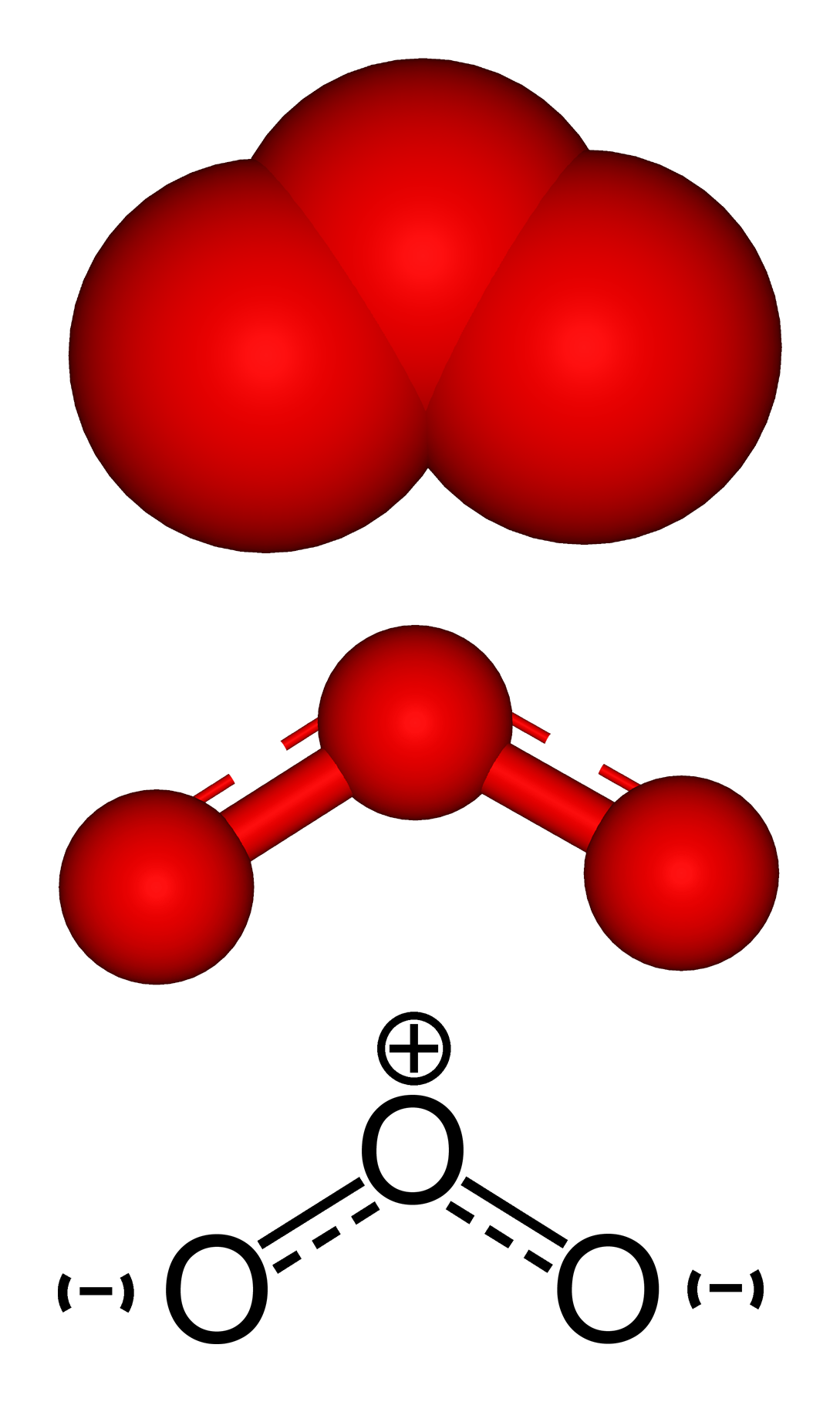

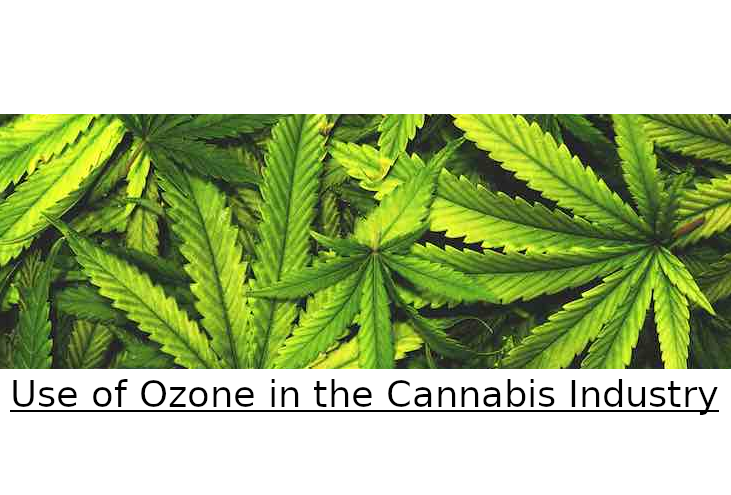

As the cannabis industry grows in the USA the interest in the use of ozone in this industry grows. There are many applications and potential uses for ozone in the cannabis industry, both in the growing and processing of cannabis. However, there are also many myths and potential misunderstandings on the use of ozone in this industry. This article will serve as a general guide to help understand the practical uses of ozone in this industry.

As the cannabis industry grows in the USA the interest in the use of ozone in this industry grows. There are many applications and potential uses for ozone in the cannabis industry, both in the growing and processing of cannabis. However, there are also many myths and potential misunderstandings on the use of ozone in this industry. This article will serve as a general guide to help understand the practical uses of ozone in this industry.

Irrigation Water Treatment:

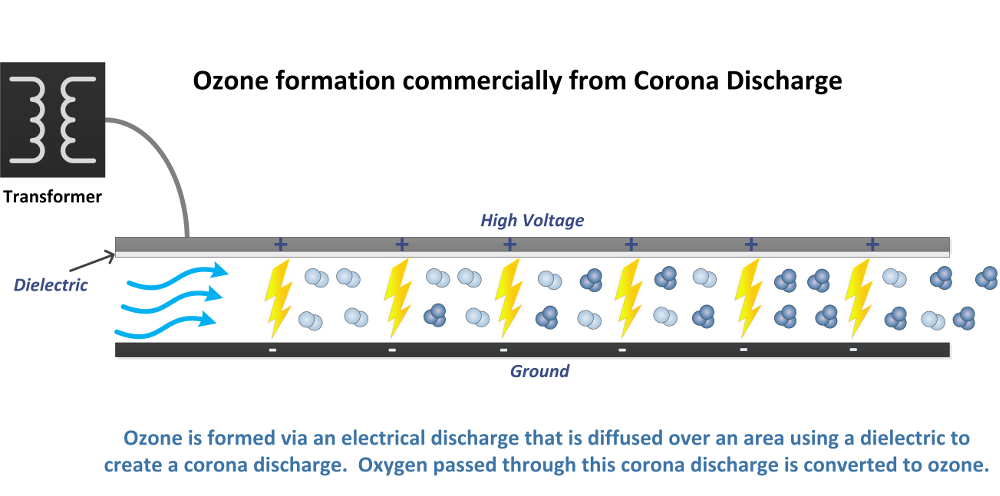

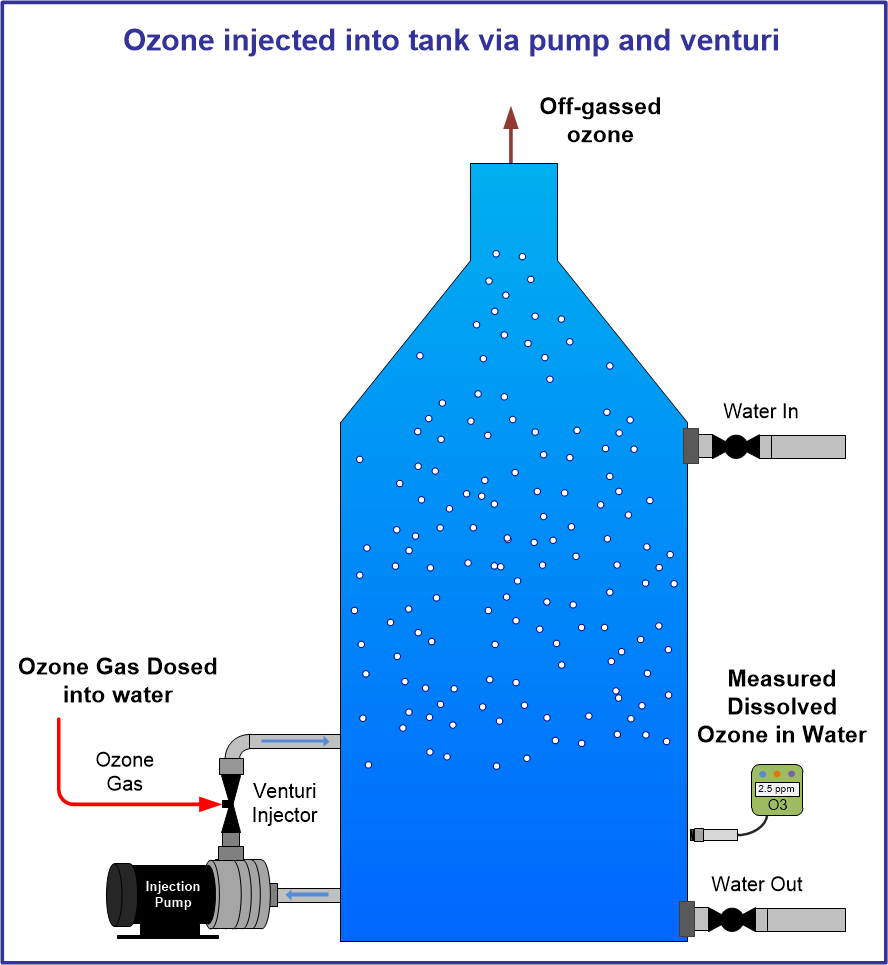

Cannabis can be grown in many ways, in each, whether indoor, outdoor, hydroponic, or other, all require irrigation water for growing the plants. This water must be clean, pure and free of pathogenic bacteria for efficient plant growth. Ozone can be used to treat general well water for removal of harmful minerals and bacteria. See link HERE for additional details on these applications. Ozone can also be used to treat other incoming water sources that may have harmful pathogens, or generally low dissolved oxygen levels due to organics in water.

Ozone is commonly used to treat well water, and city water sources for many water treatment issues. The use of ozone in water treatment is common, and is one of the oldest and most frequent uses for ozone in the world. Using the same systems and processes that would be used in other agriculture applications, or drinking water applications is applicable in the cannabis industry with no major changes to the systems or technologies.

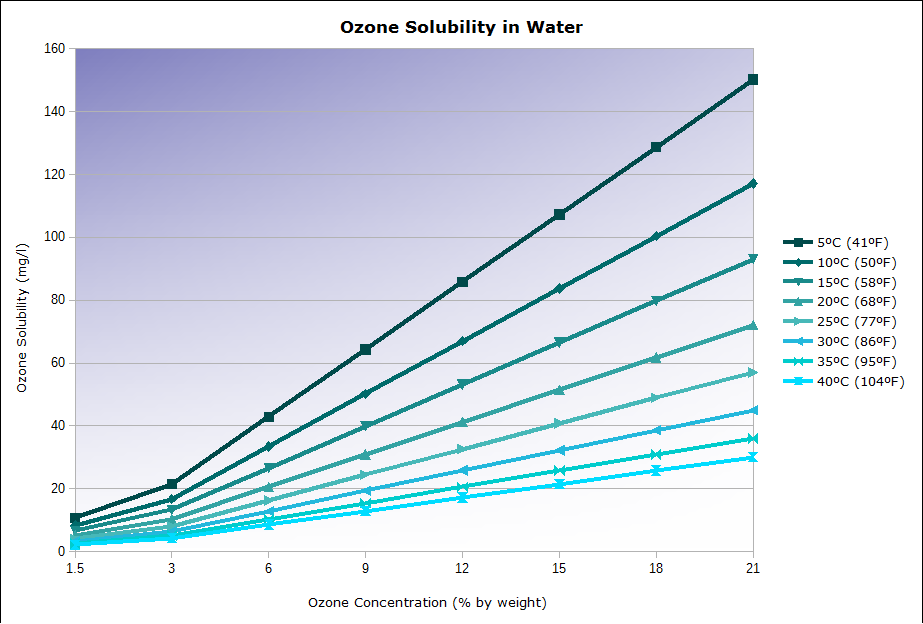

As ozone is more soluble into water than oxygen, and ozone will revert to oxygen naturally in water, adding ozone to your water will naturally increase dissolved oxygen levels in that water. Increased dissolved oxygen levels in water are always beneficial for irrigation systems.

Surface Sanitation:

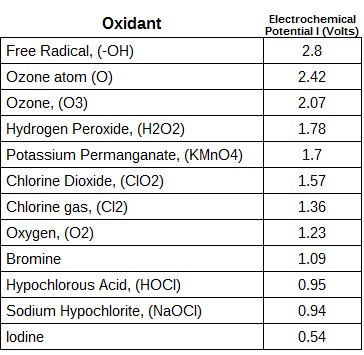

Ozone can be dissolved into water to be used for surface sanitation in rooms, equipment, and even plants if required. Ozone gas is produced, dissolved into water at high levels and used as a sanitizer. Ozone increases the ORP (oxidation-reduction potential) in the water to a level that if any of the water comes into contact with pathogens on the surface being treated.

This same application with ozone is common in the food processing industry. Many studies have been done on the use of ozone in these applications for food processing, and there are many ozone system currently in use for these applications. The same systems and processes used in the food processing industry can also be used in the horticulture and further processing of the cannabis plant.

We have provided ozone systems for surface sanitation applications by themselves. We have also supplied ozone systems capable of treating both incoming irrigation water and providing the higher dissolved ozone levels necessary for surface sanitation in one package with one ozone generation system, but 2 separate ozone mixing systems to dissolve ozone in water in two separate water streams and control individually.

Ozone in water for surface sanitation is safe, there are no harmful side-effects to humans or plants from ozone in water. However, if done incorrectly ozone in water can be off-gassed from water and enter the gas phase. Ozone in the gas phase can be harmful to both humans and plants. In this application ensure ozone is implemented and operated properly.

Odor Control:

Likely the oldest and traditionally the most common use of ozone in the cannabis growing industry, is odor control. Ozone is extremely effective at reducing organic odors and is used in many applications for odor reduction/elimination. During the growing, cultivation, and processing of the cannibis plant odors are created that can be potentially offensive. In applications where neighbors are close by or there may be aversions to any fugitive odors ozone can be used in the air exhaust of the building to eliminate odors effectively.

Cannibis Disinfection:

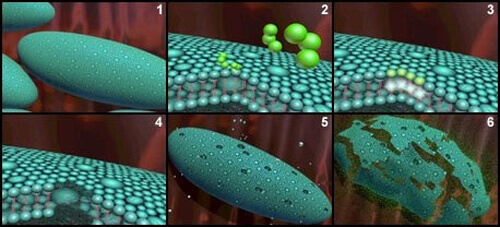

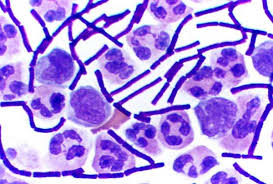

The final harvested product must meet specific mold, and bacteria standards to be sold to the end-user for consumption. There are state standards and good manufacturing processes to adhere to on mold and bacteria counts on final products. Ozone can be used to provide disinfection for this final product to met the most stringent mold and bacteria standards in your state.

Room Disinfection:

Ozone gas can be used in rooms to inactivate pathogens. Ozone gas can be used after aqueous ozone is used for surface sanitation to ensure all pathogens in the room are destroyed before starting a new crop, or between processing batches of harvested product. The room must be empty of plants and people, ozone gas can be pumped into the room at levels that would be harmful to plant, people and all pathogens. Ozone monitors can be used to control ozone levels and ensure the room is safe for re-entry when complete.

Exampe of an Ozone System:

Below is an image of an ozone system that can be used for both water treatment and surface sanitation applications in one package.

This system has a larger 30 gallon contact tank to treat high water flow-rates of incoming water with low ozone dosages for disinfection purposes. The 30-gallon tank will provide sufficient contact time with ozone to achieve disinfection with ozone. An ORP meter is used to measure and control ozone levels in water.

The smaller ozone mixing tank will provide lower water flow rates with a high dissolved ozone level (>2.0 ppm) to be used for surface sanitation applications. A dissolved ozone meter is used to measure and control ozone levels in water real-time.

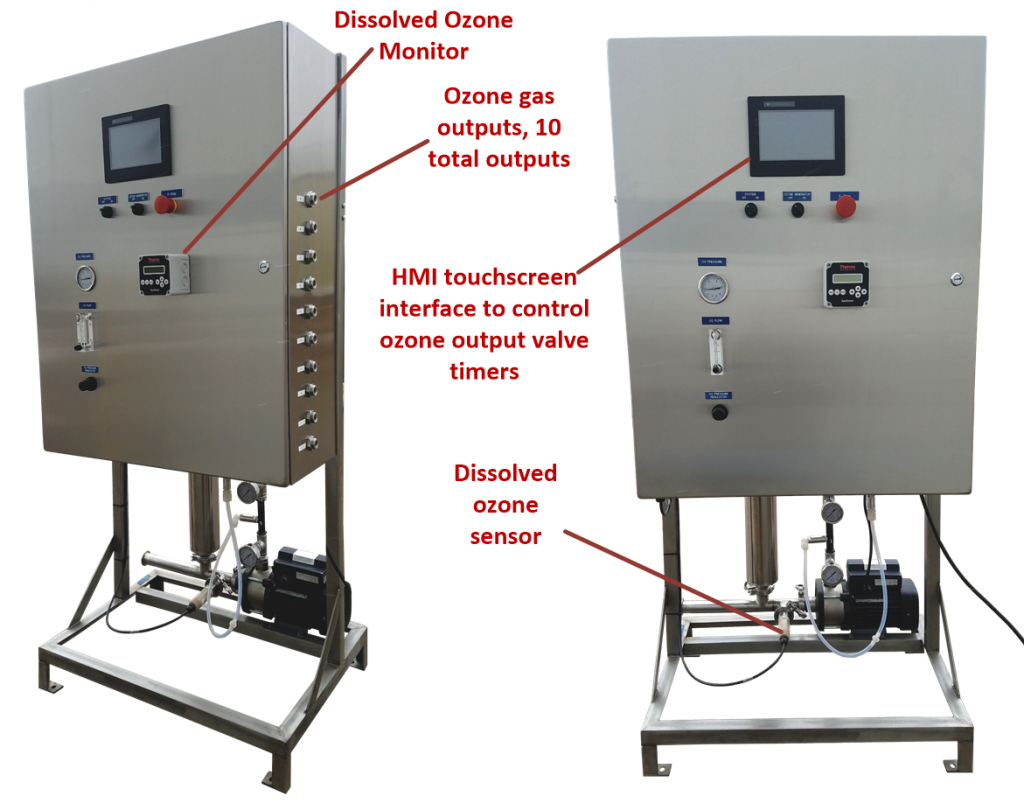

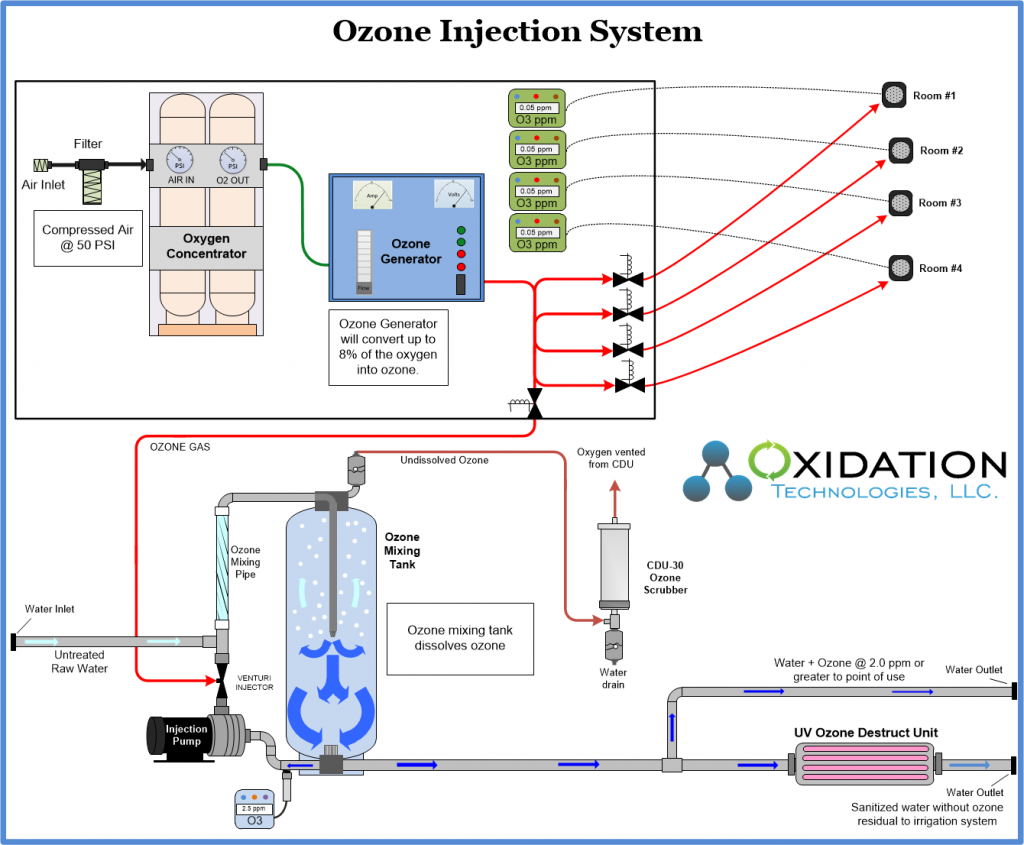

Below is an image of an ozone injection system that will dissolve ozone into water, but also includes ozone gas outlets to be used for room disinfection, odor control, or other ozone gas applications. An HMI touchscreen panel offers control of the ozone outputs via timers, and ozone monitors measuring ozone levels in each location.

Below is a diagram of how an ozone system can be configured for many various applications in the cannabis industry in one single package.

Ozone is produced via oxygen under pressure. This ozone gas is controlled and can be sent to various rooms with ozone monitors in each room. These ozone monitors will control ozone levels to proper levels for the specific application.

Ozone gas can be delivered to the venturi injector that is a part of the ozone mixing tank. This ozone in water can be plumbed directly to a point of use with a high level of ozone for sanitation applications. OR, can pass through a UV light that will safely revert all ozone back to oxygen prior to using in an irrigation system where ozone in water may be undesirable.

This system also shows an ozone destruct unit for ozone off-gas. This off-gassed ozone is reverted safely back to oxygen. This oxygen can be bubbled into an irrigation system to increase dissolved oxygen levels slightly.

As you can see, there are a wide variety of potential uses of ozone in the cannabis industry. Due to this wide variety, there is some misinformation and some myths about the use of ozone. If you would like to learn how ozone could benefit your facility, please contact our application engineers. We would be glad to help.