Compare the Mazzei Venturi Injector to the fine pore Bubble Diffuser to dissolve ozone into water

The two most common methods of dissolving ozone into water is the venturi injector and the bubble diffusion method. Each has it’s own advantages and disadvantages and applications where it might be best used.

History

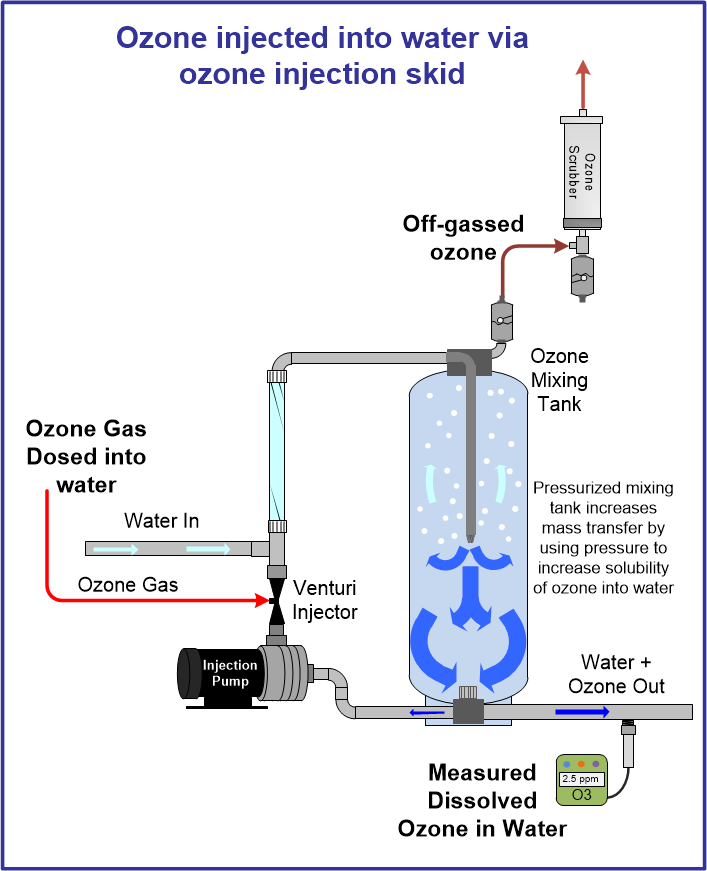

Early ozone applications used large basins or tanks and bubble diffusers as the primary method to dissolve ozone into water. Ceramic diffusers were readily available and tanks or basins offered a simple and effective method to dissolve ozone into water. As ozone applications evolved and became more popular additional methods of dissolving ozone into water were investigated. In 1983 the Mazzei Injector company started producing special ozone compatible venturi Injectors specifically for the ozone markets. This brought the venturi injector into the mainstream ozone market from the smallest to the largest water flows and applications.

While the venturi injector can offer improved mass transfer efficiencies and smaller footprints there is still a place for the simple bubble diffuser yet today.

Advantages vs Disadvantages

Fundamentals of ozone solubility:

| Bubble Diffuser Advantages: Low cost No moving parts Easy to setup Low energy – does not require water pumps or elevated water pressures Simple, reliable operation long-term | Venturi Injector Advantages: Extremely efficient ozone transfer Great option for pressurized water More ozone dissolved into water = less ozone off-gassing = safer environment Easier to contain ozone gas and maintain a safe environment due to ozone off-gassing Smaller tanks and overall footprint of the system can be achieved |

| Disadvantages: Ideal tank/basin depth for effective ozone transfer is 18-24 feet deep Ideal tank depths are not realistic in most applications causing this to be a less efficient transfer method. Diffusers can become plugged and may require periodic replacement Difficult to use in pressurized water flows | Disadvantages: Typically requires more energy than other options due to required pressure differential across venturi injector Requires flowing, pressurized water Greater risk of water backing up into the ozone generator as the water is pressurized Venturi can plug or become obstructed in contaminated water |

- – Lower temperatures increase the solubility rate of ozone gas into liquid

- – Higher pressures increase the solubility rate of ozone gas into liquid

- – Higher ozone gas concentrations increase the solubility rate of ozone gas into liquid

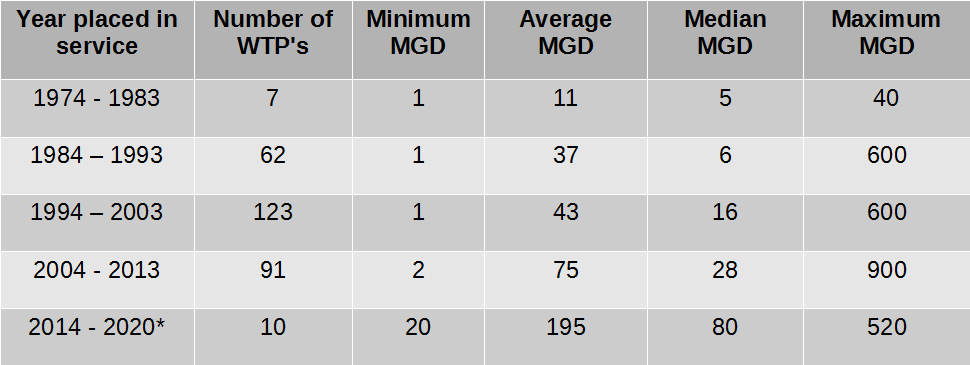

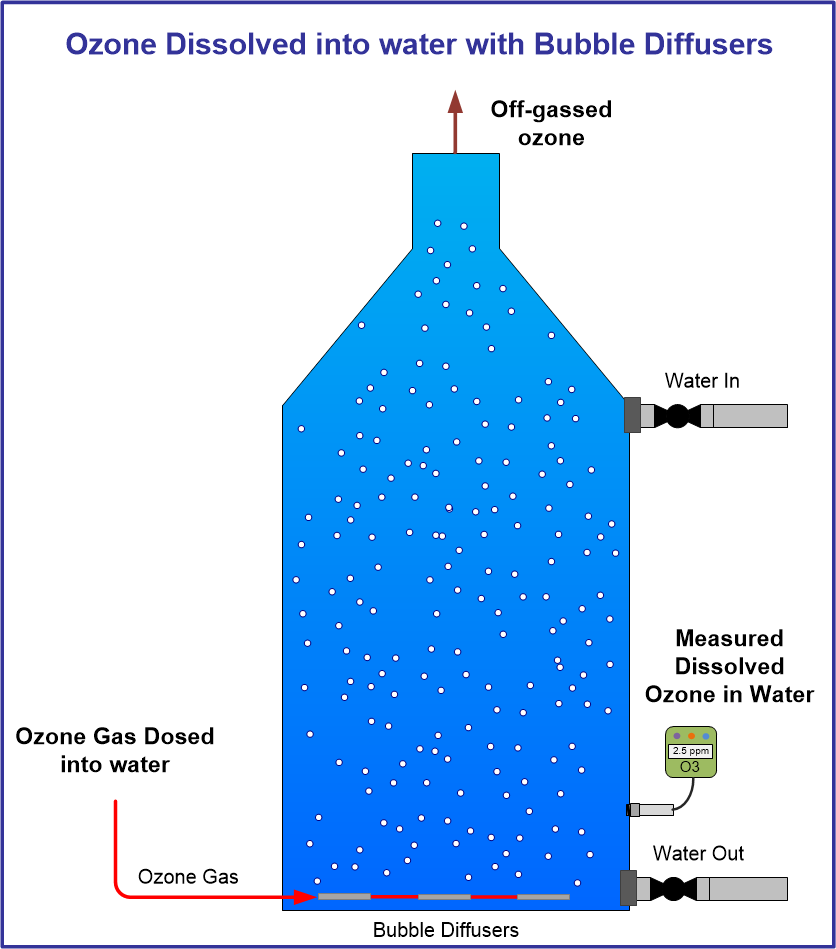

Ozone gas dissolved into a tank with a fine pore bubble diffuser Ozone gas dissolved into a tank with a fine pore bubble diffuser |  Ozone gas dissolved into a tank with a pump and venturi Ozone gas dissolved into a tank with a pump and venturi |

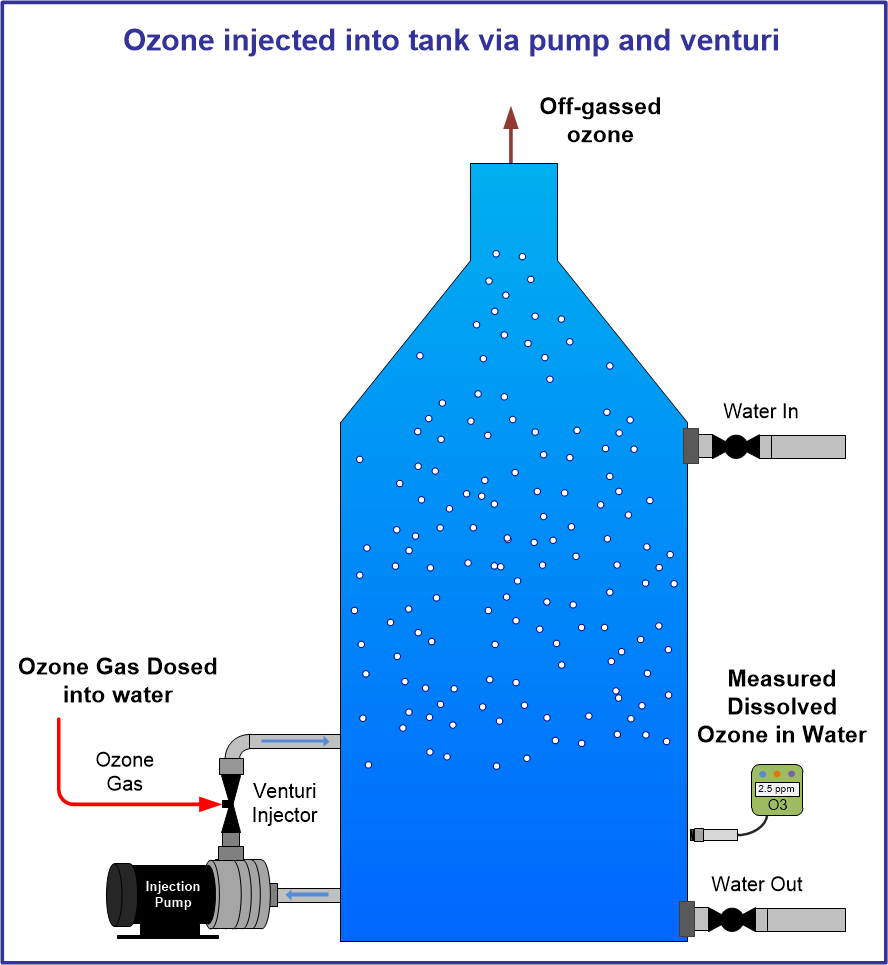

Ozone gas dissolved into water in a sealed, pressurized system with a venturi injector. Capable of dissolving ozone into pressurized water inline while safely capturing all undissolved ozone gas. Ozone gas dissolved into water in a sealed, pressurized system with a venturi injector. Capable of dissolving ozone into pressurized water inline while safely capturing all undissolved ozone gas. |

Design considerations in favor of Bubble Diffusers

- Existing tanks or contact basins on-site whose height favors the bubble diffuser should be considered

- Off-gassed ozone is more challenging to capture and handle with diffusers. If tanks are outdoors, or have proper venting in place already a diffuser may be a simple solution

- Clean water applications where low dissolved ozone levels are required are well suited for bubble diffusers as high levels of ozone transfer are not needed.

Examples of applications where Bubble diffusers may have an advantage:

- RO water holding tanks

- Bottled water applications

- Well water applications with outdoor water holding tanks

- Drinking water applications with large tanks or basins in place

Design considerations in favor of Venturi Injectors

- If higher dissolved ozone levels are required a venturi injector is ideal as high transfer efficiency will be required to achieve these dissolved ozone levels

- Varying water flow rates

- Applications where pressurized water will have ozone gas added

Examples of applications where Venturi Injectors may have an advantage:

- Sanitation applications where water is the carrier of ozone and high dissolved ozone levels are required

- New construction water treatment applications where tanks are not already in place

- Applications where footprint is a concern and space is limited

- Well water applications where ozone will be added to water under pressure