Metalworking plants have long struggled with the problems associated with coolants, including foul odors, skin rashes, tramp oil in sumps, bacterial growth, and increased costs. While many shops turn to chemical additives to temporarily alleviate these issues, they are costly and do not provide a long-term solution.

If you are looking for a safe and effective way to eliminate bacteria and biofilms from your metalworking coolant tank, ozone is a great option. Ozone can help you extend the life of your coolant and save money on replacement costs.

Learn more about this application HERE

Metalworking machines use a coolant fluid to cool and lubricate the process. This coolant is kept in a tank and circulated through the machine and metalworking process. Over time, bacteria from the air and machined products build up in the tank and cause foul odors and biofilms. Biofilms are a slimy layer of bacteria that can clog filters, screens, and pumps.

Coolant is often replaced due to the build-up of bacteria in the tank, even if the coolant is still effective as a coolant and lubricant. Replacing the coolant can be expensive, as it requires disposal, labor, and the purchase of new coolant.

Ozone Solution:

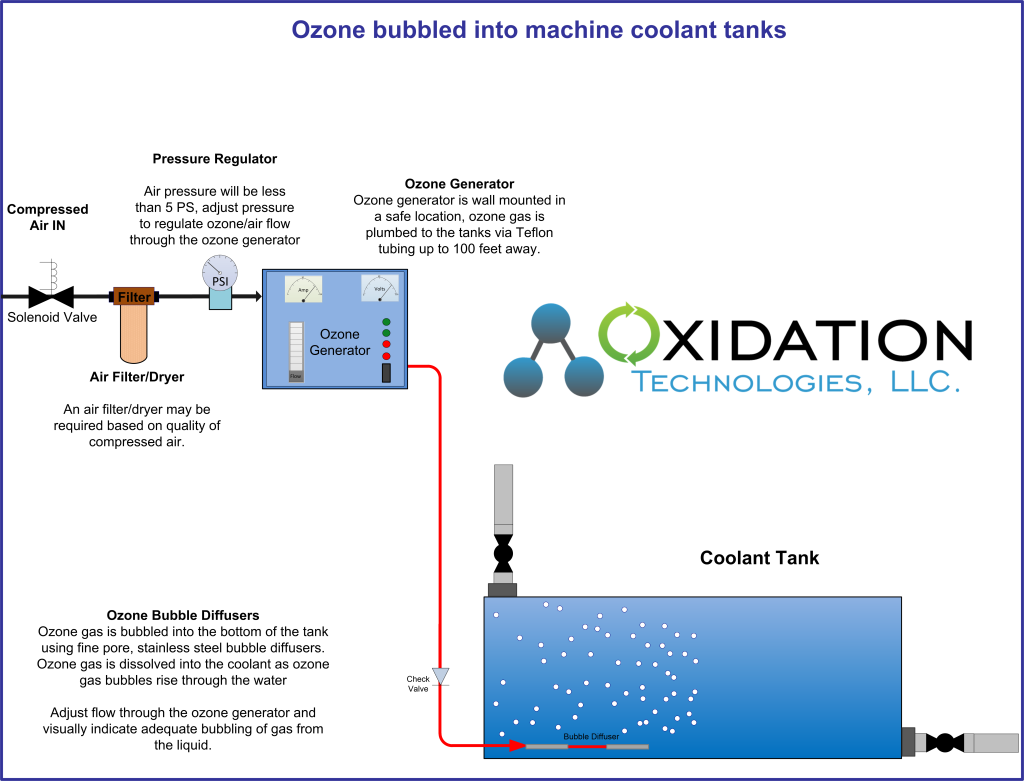

Ozone is a gas that can be used to eliminate bacteria and biofilms from metalworking coolant tanks. Ozone is generated from oxygen in the air through a process called corona discharge. The ozone gas is then bubbled into the coolant tank through a fine pore diffuser. Ozone dissolves in the coolant and kills the bacteria.

Ozone is a safe and effective way to eliminate bacteria and biofilms from metalworking coolant tanks. It is also environmentally friendly, as it does not produce any harmful emissions.

Benefits of Using Ozone:

- Ozone eliminates bacteria and biofilms, which can cause foul odors and clog filters, screens, and pumps.

- Ozone prolongs the life of coolant, which can save money on replacement costs.

- Ozone is a safe and environmentally friendly alternative to other methods of coolant treatment.

Field tests of ozone generation on metalworking fluids yielded impressive results, with longer-lasting coolant, eliminated odors, and no more skin irritation from coolant contact. Laboratory tests confirmed that there were no negative effects of ozone generation on machined parts or the coolant itself. Moreover, ozone off gas was found to be present no more than 6 to 8 inches from the sump and had no negative effects on shop personnel.

Our company, Oxidation Technologies, supplied the systems that were utilized, including the HTU-500 and other related equipment. If you wish to explore the possibility of implementing a similar system for your own needs, please feel free to get in touch with us directly or learn more about our product offerings on our website.

HTU-500: https://www.oxidationtech.com/htu500.html

Below are some images sent to us from a customer who installed an HTU-500 ozone generator on a Makino A-71NX.

This was installed at Siouland Machin, Inc in Rock Valley IA. Below is a quote from Lyle Fluit of Siouxland Machine:

“When I installed these, I added a breaker contactor and pressure switch so that if there is no shop air or if the machine is powered down the generator will shut off. It is piped directly into the bottom of the coolant tank near the primary flood coolant pump the circulates the largest volume of coolant. Prior to installation the coolant had a yellowish color, odor and foaming issues. The O-zone took care of all these issues. The coolant is cleaner, smells like it should and has stopped foaming up. We didn’t send in samples until after the initial install so I don’t have a bacteria count from before the installation.” Lyle Fluit, Siouxland Machine, Inc.

Below is a diagram of how the ozone generator would typically be installed:

If you are interested in using ozone for this application, please contact our office.