Below is a great open-source paper that was published on the use of ozone in the dairy industry. Ozone has a wide variety of potential uses in the dairy industry from water re-use, sanitation, and even medical application for dairy cows. This review gives an overview of some of these applications and some real-world examples.

Authors: László Varga, Jenő Szigeti

Abstract

Ozone treatment is a cost-effective and eco-friendly food-processing technology. It has successfully been used for the removal of milk residues and biofilm-forming bacteria from stainless steel surfaces and in milk processing, including fluid milk, powdered milk products and cheese. Ozonation has been shown to prevent mould growth on cheese and inactivate airborne moulds in cheese ripening and storage facilities. Ozone treatment has also been found to be a promising method for reducing the concentrations of pollutants in dairy wastewaters.

Introduction

Ozone (O3) is the second strongest common oxidising agent after fluorine (Guzel-Seydim et al. 2004). It was discovered by Schönbein in 1839 and was first used commercially to treat drinking water in France more than a century ago (Hill and Rice 1982; Rubin 2001). Ozonation applications in food processing have been legally approved, although to varying degrees, in North America, Australia, New Zealand, Japan and several European countries (Tiwari and Rice 2012). The specific rules and regulations issued by the US FDA with respect to ozonation of food products, including bottled water, have triggered increased global interest in the use of ozone for food treatment and processing purposes (United States Department of Health and Human Services, Food and Drug Administration 2001; O’Donnell et al. 2012a; Tiwari and Rice 2012). In many parts of the world, ozonation is becoming more and more widely accepted in the food industry as an eco-friendly green technology (Pascual et al. 2007; O’Donnell et al. 2012a).

A number of reviews, book chapters and books have been published on the use of ozone in the food industry over the past decade (Guzel-Seydim et al. 2004; Wysok et al. 2006; Pascual et al. 2007; Freitas-Silva and Venâncio 2010; O’Donnell et al. 2012b; Patil and Bourke 2012). Recent developments of note include approaches involving the combined use of ozone and other advanced food-processing methods, such as washing with electrolysed water, ultrasound treatment, ultraviolet irradiation and modified atmosphere packaging (Baumann et al. 2009; Steffen et al. 2010). Mention must also be made of a novel in-package ionisation (plasma) technology whereby significant levels of ozone are generated inside sealed packages of food products using high-voltage, low-current electrodes placed below and above the package (Klockow and Keener 2009). Such approaches are suitable for a variety of food applications, from meat products to fresh produce (O’Donnell et al. 2012a; Tapp and Rice 2012). To our knowledge, this is the first comprehensive review of the use of ozone in the dairy industry.

Physical properties and generation of ozone

The major physical properties of ozone are shown in Table 1. Ozone, a bluish gas with pungent smell, is an extremely reactive and unstable allotrope of oxygen (O2) possessing a high oxidation potential of −2.07 V that conveys broad-spectrum antimicrobial properties. It is produced by the reaction of free oxygen radicals with O2 molecules. Numerous methods exist for the generation of ozone, including electric corona discharge, ultraviolet radiation, thermal, chemical, electrolytic and chemonuclear methods (Horvath et al. 1985; Kim et al. 1999; Khadre et al. 2001; Patil and Bourke 2012). Table 1. Physical properties of ozone (Manley and Niegowski 1967; Rice et al. 1981; Kim et al. 1999; Khadre et al. 2001; Guzel-Seydim et al. 2004)

| Parameter | Value |

|---|---|

| Molecular weight | 48 |

| Density (kg/m3) | 2.14 |

| Boiling point (°C) | −111.9 |

| Melting point (°C) | −192.6 |

| Critical temperature (°C) | −12.1 |

| Critical pressure (atm) | 54.6 |

| Oxidation potential (V) | −2.07 |

| Solubility in water at 0 °C (L/L) | 0.640 |

| Solubility in water at 15 °C (L/L) | 0.456 |

| Solubility in water at 40 °C (L/L) | 0.112 |

| Solubility in water at 60 °C (L/L) | 0.000 |

Benefits of ozone usage in food processing

Despite being a highly effective disinfectant, ozone does not leave a chemical residue on either food or food contact surfaces because it quickly autodecomposes to nontoxic products, thereby reducing both the environmental impacts and costs of the company (Khadre et al. 2001; Pascual et al. 2007; Cullen and Norton 2012; O’Donnell et al. 2012a; Patil and Bourke 2012). Another advantage of the application of ozone in food-processing operations is that ozone can be generated on-demand on-site and, as opposed to conventional chemical sanitisers, it requires neither transportation nor storage (Khadre et al. 2001; Pascual et al. 2007; Cullen and Norton 2012). In addition, the running costs of ozonation systems are low because they only consume a limited amount of electricity (Pascual et al. 2007).

Factors influencing ozonation efficiency

The efficacy of ozone in food-processing applications is affected by a range of variables, including treatment temperature, pH value, relative humidity and the quantity of ozone-consuming compounds, because all these factors differently affect the solubility, reactivity and stability of ozone (Khadre et al. 2001; Cullen and Norton 2012).

As temperature increases, ozone becomes less stable and less soluble but more reactive. Therefore, temperature should be carefully controlled during ozonation in order to maintain a balance in solubility, stability and sanitising efficacy (Kim et al. 1999; Khadre et al. 2001; Cullen and Norton 2012). As for pH, it is widely accepted that ozone is less stable at high than at low pH values. However, when ozone autodecomposes at high pH values, the radicals formed evidently contribute to its efficacy (Khadre et al. 2001; Cullen and Norton 2012). As far as humidity is concerned, microbial destruction rates are greater when ozone is used in an atmosphere having an increased relative humidity (Ewell 1946; Kim et al. 1999). Finally, dissolved organic matters are known to reduce the disinfection rate by competing with the micro-organisms for ozone. Hence, the absence of organic compounds in ozonated water to be used in food processing is highly desirable (Khadre et al. 2001; Cullen and Norton 2012; Patil and Bourke 2012).

Inactivation of micro-organisms and microbial products by ozonation

Microbial inactivation by ozonation is a complex process. Ozone is capable of attacking various constituents in cell membranes, cell walls, the cytoplasm, endospore coats, virus capsids and viral envelopes (Khadre et al. 2001; Patil and Bourke 2012). It is noteworthy that the double bonds of unsaturated fatty acids are especially vulnerable to ozone attack (Guzel-Seydim et al. 2004). The powerful antimicrobial properties of ozone are due to its previously mentioned high oxidation potential and its capability to diffuse through biological membranes (Hunt and Mariñas 1997).

As a general rule, all micro-organisms have an inherent sensitivity to ozone (Patil and Bourke 2012). Moulds are more resistant than yeasts, and yeasts are more resistant than bacteria, with gram-negative bacteria being even more sensitive than gram positives. Ozone is less effective against both fungal and bacterial spores than vegetative cells (Kim et al. 1999; Moore et al. 2000; Khadre et al. 2001; Pascual et al. 2007; Cullen and Norton 2012; Patil and Bourke 2012). Viruses are similar to bacteria in sensitivity to ozone with bacteriophages showing the least resistance (Khadre et al. 2001). It should also be noted that ozone was successfully used to detoxify commonly occurring mycotoxins by either completely degrading them or causing chemical modifications, thus considerably reducing their bioactivity (McKenzie et al. 1997; Lemke et al. 1999; Freitas-Silva and Venâncio 2010; Patil and Bourke 2012).

Health and safety aspects of ozone application

Exposure to ozone at low concentrations of around 0.1 mg/L only causes irritation to the eyes, throat and nose, whereas ozone levels as high as 95 mg/L can even have irreversible lethal effects on humans (Khadre et al. 2001; Cullen and Norton 2012). Therefore, efficacious systems for the detection and catalytic or thermal destruction of ozone are reasonably required for the safety of personnel in food-processing plants (Kim et al. 1999). This is especially important if ozone is used in the gaseous form. In such cases, a continuous ozone analyser must be installed which triggers a general alarm (i.e. both acoustic and visual warning signals) as soon as the concentration of ozone exceeds 0.1 ppm (equalling 0.2 mg/m3) in the atmosphere of the ozonation room (Damez et al. 1991; Khadre et al. 2001; Cullen and Norton 2012).

Use of Ozone on Dairy Farms

Implementation of good hygienic practices on dairy farms is a prerequisite for the production of high-quality and microbiologically safe raw milk. Given that ozone is a powerful oxidising agent active against a wide range of micro-organisms, including viruses, bacteria, yeasts, moulds and protozoa (Restaino et al. 1995; Kim et al. 1999; Moore et al. 2000; Khadre et al. 2001; Fontes et al. 2012; Patil and Bourke 2012), ozone treatment can be applied on dairy farms for a variety of reasons and purposes.

The pipelines, which carry the milk from individual milking stations to the bulk tank, have to be cleaned after every milking. Hot water with chemicals is generally used in the cleaning and disinfection processes consuming a large amount of energy and chemicals. The use of ozone can considerably lower chemical costs and completely eliminate hot water costs on dairy farms. Heacox (2013) filed a patent for an ozone delivery method, system and apparatus whereby ozonated water, containing ozone at a preferable level of 0.04–1.2 ppm, is used to clean and disinfect dairy animals, milking equipment and various surfaces in dairy settings. If the hind legs, udder and teats of cows are thoroughly washed off with ozonated water prior to milking, many hygienic problems may easily be prevented (Ozone Systems 2014).

Ozone has even been successfully used to treat bovine mastitis (Ogata and Nagahata 2000), the costliest and most common disease in dairy production (Peles et al. 2007). When 6–30 mg of ozone was infused into each inflamed udder quarter of cows with acute clinical mastitis, 60% of sick animals completely recovered without administration of antibiotics. In these cases, the efficacy of ozone therapy was identical to that of an antibiotic treatment. The authors have concluded that ozone therapy is a safe, effective and inexpensive method of curing mastitis without leaving antibiotic residues in raw milk (Ogata and Nagahata 2000).

Another use of ozone on dairy farms is its addition, at very low concentrations, to the air in the barn in order to destroy airborne pathogens and eliminate manure smell in the barn (Ozone Systems 2014).

Use of Ozone in Dairy Processing

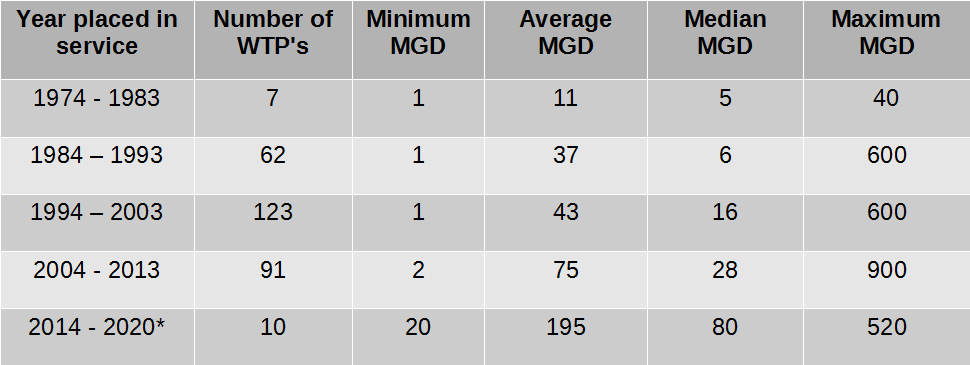

The major dairy processing applications of ozone are reviewed in the following subsections and are also summarised by category in Table 2. Table 2. Major dairy processing applications of ozone

| Category of application | Treatment | Target | Result | Reference |

|---|---|---|---|---|

| Removal of milk residues and biofilm-forming bacteria from stainless steel surfaces | Ozonated cold water (10 °C) for 15 min | Heated dairy soil (reconstituted nonfat dry milk, 20% total solids) on metal plates | 84% of dairy soil removed from plates | Guzel-Seydim et al. (2000) |

| Ozonated water (40 NL/h, 80 g/Nm3) in a bath-substrate-flow device for up to 30 min | Heat-denatured whey protein concentrate (WPC) on stainless steel coupons | Increased WPC removal rates within 10 min compared to treatment with 0.5% (w/w) NaOH solution | Jurado-Alameda et al. (2014) | |

| Gaseous ozone pretreatment (0.1–0.5%, v/v) | Heat-treated bovine serum albumin (BSA) on stainless steel particles | Increased BSA desorption rates during subsequent caustic alkali cleaning | Fukuzaki (2006) | |

| Ozonated deionised water (0.5 ppm for 10 min) | Pseudomonas fluorescens ATCC 949 and Alcaligenes faecalis ATCC 337 in UHT milk biofilm on stainless steel plates | 5.6 and 4.4 log10 cfu/cm2 reductions, respectively | Greene et al. (1993) | |

| Ozonated phosphate-buffered saline (0.6 ppm for 10 min) | Pseudomonas spp. in UHT milk biofilm on stainless steel coupons | Approximately 3–4 log10 cfu/in2 reductions in Pseudomonas populations | Dosti et al. (2005) | |

| Gaseous ozone (2 ppm for 4 h) | Escherichia coli ATCC 25922, Listeria innocua, Serratia liquefaciens, Staphylococcus aureus and Rhodotorula rubra in UHT milk biofilm on stainless steel squares | Up to 5.64 log10 cfu/cm2 reductions in microbial viability | Moore et al. (2000) | |

| Distilled, deionised water treated with pulsed ozone (0.4–0.5 ppm) applied for 20 min/d for 7 d at 21–23 °C | Metal materials (plates) used as food contact surfaces in dairy processing | Significant weight loss of carbon steel plates (P <0.05) | Greene et al. (1999) | |

| Fluid milk | ‘Mild’ ozone treatment (parameters unknown) | Milk and fluid milk products | Minimised deterioration of product quality | Sander (1985) |

| Pressurised ozone (5–35 mg/L for 5–25 min) | Microbial population of skim milk | 2.4 log10 cfu/mL reduction in psychrotrophic counts | Rojek et al. (1995) | |

| Gaseous ozone (generation rate: 0.2 g/h) | Listeria monocytogenes in commercial raw and branded milk samples (mean viable counts: 5.5 and 5.7 log10 cfu/mL, respectively) | Complete elimination of Listeria monocytogenes after 15 min | Sheelamary and Muthukumar (2011) | |

| Gaseous ozone (1.5 mg/L for 5–15 min) | Microbiota of raw milk (mean total plate count: 4.18 log10 cfu/mL) | Up to 1 log10 cfu/mL reductions in bacterial and fungal counts after 15 min | Cavalcante et al. (2013a) | |

| Gaseous ozone pretreatment (concentration and duration unspecified) followed by pasteurisation | Raw milk | Shelf life extension without excessive lipid or protein oxidation in final product (commercial fluid milk) | Pastair (2014) | |

| Powdered milk products | Gaseous ozone (2.8 mg/L or 5.3 mg/L for 0.5–2 h) | Cronobacter sakazakii ATCC 51329 in skim milk powder (SMP) and whole milk powder (WMP) at 5.92 log10 cfu/g | Log10 cfu/g reductions of approximately 3 (SMP) and 1.4 (WMP) in Cronobacter counts after 2 h | Torlak and Sert (2013) |

| Gaseous ozone (2 ppb or 32 ppb during manufacture of milk powders) | SMP and WMP | Decreasing sensory scores with increasing background ozone levels and fat contents | Kurtz et al. (1969) | |

| Gaseous ozone (treatment parameters unknown) | WMP | Negative effect on organoleptic properties due to lipid oxidation | Ipsen (1989) | |

| Gaseous (60 g/h) or aqueous (4.5 ppm) ozone for up to 15 min | Whey protein isolates (WPI) | Enhanced foam formation and foam stability, whereas reduced solubility and emulsion stability of WPI | Uzun et al. (2012) | |

| Gaseous ozone (approximately 20 mg/L for 30–480 min) | WPI | Improved foaming capacity and foam stability, whereas reduced solubility of WPI | Segat et al. (2014b) | |

| Cheese and indoor atmosphere in cheese ripening and storage rooms | Gaseous ozone (3–10 ppm for up to 30 d) | Heavy mould growth on Cheddar cheese | Mould growth inhibition without mould destruction (fungistatic effect); and 94% reduction in mould spore counts in the air of storage room | Gibson et al. (1960) |

| Gaseous ozone (0.2–0.3 ppm for up to 63 d) | Mould growth on Cheddar cheese | Mould growth inhibition on the sides of cheese; and 88% reduction in mould spore counts in the air of storage room | Gibson et al. (1960) | |

| Gaseous ozone (2.5–3.5 ppm for 4 h at 2- to 3-day intervals) | Russian- and Swiss-type cheeses | Mould growth inhibition on cheeses and packaging materials up to 4 months of refrigerated storage | Gabriel’yants’ et al. (1980) | |

| Gaseous ozone (4 ppm for 8 min) | Italian cheeses spiked with Listeria monocytogenes (up to 3 log10 cfu/g) at different stages of ripening | Complete elimination of L. monocytogenes only from cheeses contaminated during the first week of ripening | Morandi et al. (2009) | |

| Ozonated water (2 mg/L for 1–2 min) | Microbiota of Minas Frescal cheese | Approximately 2 log10 cfu/g reduction in initial bacterial and fungal counts (P <0.05) | Cavalcante et al. (2013b) | |

| Pre-ozonated (2 mg/L) cooling water (15 °C) | Microbiota of high-moisture mozzarella cheese | By 3.58 and 6.09 log10 cfu/g lower total plate counts and Pseudomonas spp. counts, respectively, than in control mozzarella samples cooled with nonozonated water, following 21 d of storage | Segat et al. (2014a) | |

| Gaseous ozone (up to 5 ppm) | Air of cheese ripening room | Up to 99% decrease in viable counts of airborne moulds | Shiler et al. (1978) | |

| Gaseous ozone (generation rate: 4–8 g/h) for 20 wk | Air of cheese ripening room | Tenfold reduction in viable airborne mould load (to < 50 MPN/m3), with majority of isolates belonging to Penicillium spp. | Serra et al. (2003) | |

| Gaseous ozone (0.24 ppm for 40 d) | Parmesan-type cheese surfaces, shelf surfaces and air of cheese ripening room | 0.74, 0.93 and 2.07 log10 reductions, respectively, in fungal viable counts (P <0.05) | Pinto et al. (2007) | |

| Gaseous ozone (0.38 ppm for 60 d) | Air of cheese ripening room | 63% decrease in viable counts of airborne yeasts and moulds | Lanita and da Silva (2008) | |

| Wastewater treatment in dairy processing | Gaseous ozone (treatment parameters unknown) | Dairy effluent with 80–230 mg/L of fat content | 96–98% decrease in fat content | Loorits et al. (1975) |

| Gaseous ozone pretreatment (150 mg/L/h for 60 min) | Dairy wastewater with 6100 mg/L of chemical oxygen demand (COD) | Enhanced COD removal and increased biodegradability of retentate during subsequent nanofiltration (4.0 MPa at 20 °C) | László et al. (2007) | |

| Gaseous ozone treatment (30 mg/L for 5–20 min) | Model dairy wastewater with 4000 mg/L of COD | Up to 25% decrease in COD | László et al. (2009) | |

| Gaseous ozone pretreatment (30 mg/L for 5–20 min) | Model dairy wastewater with 4000 mg/L of COD | Increased flux and decreased membrane fouling during subsequent nanofiltration (3.0 MPa at 25 °C) | László et al. (2009) | |

| Gaseous ozone pretreatment (2 g/h for 240 min at pH 7–12) | Dairy wastewater with 6300 mg/L of COD | High COD removal efficiency (71%) at pH 12 | Sivrioğlu and Yonar (2015) | |

| Ultrasonication (76.4 kJ/kg TS of specific energy) followed by gaseous ozone pretreatment (0.0011 mg O3/mg SS) | Dairy waste activated sludge with soluble COD, suspended solids (SS) and total solids (TS) levels of 400, 7000 and 12 560 mg/L, respectively | Enhanced COD solubilisation, SS reduction and anaerobic biodegradability (compared to single pre-ozonation) | Packyam et al. (2015) | |

| Gaseous ozone (10 g/Nm3 for up to 7 h at pH 2–10) | Biologically pretreated cheese whey wastewater with 520 mg/L of COD | Substantial decrease in COD, especially when ozonation was combined with application of 16.5–33.0 mM of H2O2 | Martins and Quinta-Ferreira (2010) |

Removal of milk residues and biofilm-forming bacteria from stainless steel surfaces

A prerinse with warm water is normally the first step in cleaning dairy processing equipment in order to remove the bulk of milk residues (aka dairy soil). Guzel-Seydim et al. (2000) quantified and visualised the effectiveness of warm water (40 °C) and ozonated cold water (10 °C) as a prerinse for removing dairy soil from stainless steel plates. Scanning electron micrographs showed that the metal surfaces were cleaned more efficiently by ozonation than by the 40 °C warm water treatment. According to the results of chemical oxygen demand (COD) measurements, ozonated water removed 84% of milk residues from plates, whereas the nonozonated warm water treatment removed only 51% of dairy soil materials, but the two values did not differ significantly (P >0.05). Similarly, Fukuzaki (2006) and Jurado-Alameda et al. (2014) studied the suitability of ozone for removal of heat-denatured whey proteins from stainless steel surfaces. Both aqueous and gaseous ozonation facilitated whey protein desorption.

The micro-organisms adhered to milk contact surfaces are hard to destroy and may cause deterioration in the microbiological quality of milk and dairy foods. Ozonation is a possible alternative to the chlorine-based sanitisers widely used in the dairy industry (Guzel-Seydim et al. 2004). Greene et al. (1993) found that ozonated deionised water containing 0.5 ppm of ozone was capable of reducing the populations of common psychrotrophic milk spoilage bacteria (Pseudomonas fluorescens and Alcaligenes faecalis) on stainless steel plates by more than 4 log10 cycles during a 10-min exposure time. The effectiveness of ozonated water against biofilms of P. fluorescens and A. faecalis was superior to that of a commercial chlorinated sanitiser used at 100 ppm for 2 min. Similar findings were reported by Dosti et al. (2005), who determined that both ozone (0.6 ppm for 10 min) and chlorine (100 ppm for 2 min) significantly reduced the populations of three Pseudomonas species in biofilms on stainless steel coupons, as compared to the control (P <0.05). It is also worth noting that the combined application of ozone and power ultrasound is even more effective for bacterial biofilm removal than either treatment alone (Bott and Liu 2004; Krasnyj et al. 2008; Baumann et al. 2009).

However, the use of ozonated water can only be recommended to replace warm water and chlorine for cleaning and sanitising purposes, respectively, if the surfaces of dairy processing equipment are not adversely affected. In a trial by Greene et al. (1999), approximately 0.4–0.5 ppm of ozone pulsed into water at 21–23 °C for 20 min per day over a 7-day period caused a certain degree of weight loss of all materials tested (i.e. aluminium, copper, stainless steel and carbon steel). It was therefore concluded that special attention is required when pulsed ozonation is applied to dairy chilling water systems containing copper or carbon steel parts.

Fluid milk

Raw milk is traditionally treated with thermal processes in order to be safe for human consumption. Heating, however, may negatively influence both the nutritional value and the sensory properties of milk. For this reason, Sander (1985) patented a method for the mild ozone treatment of liquids, including milk and fluid dairy foods, thereby minimising their possible quality deterioration. Rojek et al. (1995) used pressurised ozone (5–35 mg/L for 5–25 min) to preserve skim milk by decreasing its microbial populations. The treatment was shown to reduce the number of psychrotrophs by more than 99%. Sheelamary and Muthukumar (2011) completely eliminated Listeria monocytogenes from both raw and branded milk samples through ozonation.

In a recent study, the efficacy of microbial inactivation in raw milk by ozone treatment was evaluated (Cavalcante et al. 2013a). Ozone gas bubbling at 1.5 mg/L for 15 min was found to reduce bacterial and fungal counts by up to 1 log10 cycle. Ozonation alone, therefore, was not capable of killing a sufficiently high percentage of the microbiota of raw milk.

A gentle process involving pre-ozonation followed by a conventional pasteurisation step has been developed by a Swedish company (Pastair 2014). The treatment is claimed to result in commercial fluid milks with an extended shelf life without causing excessive lipid or protein oxidation in the final products.

Powdered milk products

Cronobacter spp., previously known as Enterobacter sakazakii, have recently been associated with fatal neonatal infections (Joseph and Forsythe 2011). These organisms are frequently isolated from milk powder and the environments of dried milk production facilities (Kandhai et al. 2004; Torlak and Sert 2013). Ozonation was shown by Torlak and Sert (2013) to be an effective method of destroying Cronobacter sakazakii ATCC 51329 cells in milk powders, especially in dried skim milk. The authors exposed whole and skim milk powder samples to gaseous ozone at concentrations of 2.8 mg/L or 5.3 mg/L for 0.5–2 h. Both ozone levels reduced Cronobacter counts in skim milk powder by approximately 3 log10 orders following 120 min of exposure. The effectiveness of ozone treatment was, however, adversely affected by the presence of fat in the product, because a reduction of only <2 log10 units was observed in the viability of C. sakazakii in whole milk powder after 2 h of gaseous ozonation.

Ozone treatments may also influence the chemical, physical, functional and organoleptic properties of dried milk products. Spray-dried skim milk powders manufactured under a background ozone level of 32 ppb received significantly lower sensory scores from a trained taste panel than those produced in air containing 2 ppb of ozone (Kurtz et al. 1969). In the same study, whole milk powders were shown to suffer more ozone damage than skim milk powders, suggesting that reactions between milk fat and ozone were responsible for the off-flavour produced. These observations were later confirmed by Ipsen (1989), who reported a negative effect of ozone on the sensory quality of dry whole milk due to lipid oxidation.

Uzun et al. (2012) treated whey protein isolates with gaseous and aqueous ozone. According to their results, ozonation substantially enhanced the foaming capacity and foam stability of proteins; however, both the solubility of whey proteins and the emulsion stability were reduced. It is noteworthy that gaseous ozone treatments decreased the solubility of protein samples to a greater degree than did aqueous ozonation. Similar findings were reported by Segat et al. (2014b), who concluded that tailored whey proteins with specific functionality may be developed through ozone processing.

Cheese and indoor atmosphere in cheese ripening and storage rooms

Ozone was used in cheese-storage facilities first in the USA as early as in the 1940s (Brunner 1958; Tiwari and Rice 2012). Some years later, the application of ozone at low levels to prevent mould growth on cheese during ripening was recommended by various authors (Ewell 1950; Walter 1951). Gibson et al. (1960) employed two ozone concentrations to combat a well-established mould growth and inhibit mould development on Cheddar cheese. High-ozone levels of 3–10 ppm appeared to destroy heavy mould growth, but a few days after ozonation was stopped, a profuse growth of mould developed on Cheddar cheese samples, indicating that the moulds were not killed. Even low-ozone concentrations of 0.2–0.3 ppm were observed to remarkably decrease the relative size of mould-covered areas on cheese surfaces. The high-ozone and low-ozone treatments also reduced the mean mould spore counts in the curing rooms by 94% and 88%, respectively. No flavour defects resulting from the ozone treatments were detected in any of the cheese samples tasted.

Volodin and Shiler (1978) tested the usability of various plastic films for cheese packaging purposes. They found that thick films (37–480 μm) were not permeable to ozone, whereas thin films (12 μm), because of their ozone permeability, were suitable for ozone-based surface sterilisation of packaged cheese.

Gabriel’yants’ et al. (1980) stored Russian- and Swiss-type cheeses under refrigeration (2–4 °C, 85–90% RH) with or without ozonation of the air in the storage room. Periodical treatments with 2.5–3.5 ppm of ozone for 4 h at 2- to 3-day intervals prevented mould growth on both cheeses and packaging materials for at least 4 months without adversely affecting the sensory properties and chemical composition of the cheese. By comparison, mould growth was observed on control cheese following 1 month of storage. In another trial, the application of 10 ppm of ozone during cheese ripening increased the shelf life of products to 11 weeks (Horvath et al. 1985).

In a study by Morandi et al. (2009), three types of Italian cheese (i.e. Ricotta Salata di Pecora, Taleggio PDO and Gorgonzola PDO) were artificially surface-contaminated with up to 103 colony-forming units (cfu)/g of L. monocytogenes T20 at various stages of the ripening process and were then treated with 4 ppm of gaseous ozone for 8 min. Ozonation reduced L. monocytogenes counts to below 10 cfu/g in ricotta. As for Taleggio and Gorgonzola, ozone treatment was only effective against the test organisms during the first 6 and 3 days, respectively, of the ripening period. It is also worth mentioning that ozonation retarded the process of cheese ripening.

The microbiological quality of a Brazilian fresh cheese, Minas Frescal, treated with ozonated water (2 mg/L) for 1–2 min was monitored during refrigerated storage (Cavalcante et al. 2013b). Ozonation reduced the initial counts of total aerobic mesophiles, lactic acid bacteria, yeasts and moulds by approximately 2 log10 cycles; however, it did not affect the growth or survival rates of these micro-organisms throughout the 30-day storage period. The ozone treatments applied induced no changes in the physicochemical properties of Minas Frescal cheese samples.

Segat et al. (2014a) evaluated the efficacy of different ozone treatments for decreasing the viable counts of spoilage bacteria during mozzarella cheese production. Ozone proved incapable of disinfecting cheese surfaces when samples were (a) packaged with preserving liquid containing 2 mg/L of ozone or (b) contaminated with 107 cfu/g of Pseudomonas spp. and then placed in ozonated water (2–10 mg/L) for 60 min or (c) treated with gaseous ozone (10–30 μg/L) for up to 2 h. By contrast, mozzarella cheese samples cooled in water pretreated with 2 mg/L of ozone were characterised by low microbial counts, as compared to the control cheese. The authors concluded that ozone treatment of tap water used in several steps of mozzarella cheesemaking improves the microbiological quality of finished products, thereby increasing their shelf life.

Cheese ripening rooms have a special environment that encourages mould growth. Therefore, if the room is contaminated with mould spores, unpackaged cheese will most likely become mouldy. Ozonation is an effective method for inactivating airborne moulds (Cullen and Norton 2012).

Shiler et al. (1978) reported that ozone concentrations of approximately 0.05 ppm and 5 ppm in the air of a cheese ripening room inactivated 80–90% and 99%, respectively, of mould spores without negatively influencing the organoleptic properties of cheeses. The same group of researchers developed a method for ozonation during cheese ripening and storage to inactivate contaminating micro-organisms, thus improving the hygiene of cheesemaking. For best results, ozone treatments were carried out for 1–3 h each day at ozone concentrations of 40–50 ppb in the atmosphere with intervals of 2–12 h, and every 10–30 days the chambers were treated with ozone at the rate of 4–6 ppm for 2–4 h (Shiler et al. 1983).

In a later experiment, a cheese ripening room was ozonated for 20 weeks, and the effectiveness of the treatment was monitored on a weekly basis both in the air of the room and on surfaces (Serra et al. 2003). Ozone gas proved to be very effective in reducing the total numbers of viable mould spores in the atmosphere of the closed cheese ripening room, whereas it failed to decrease the viable mould load on surfaces. It was concluded that gaseous ozonation might not eliminate the growth of moulds already present on the surface of cheese entering the ripening room; however, it might reduce or prevent the sedimentation of airborne moulds during the ripening process (Serra et al. 2003). In a 40-day trial by Pinto et al. (2007), gaseous ozone treatment caused decreases of 0.74, 0.93 and 2.07 log10 cycles (P <0.05) in fungal viable counts on extra-hard cheese and shelf surfaces and in the atmosphere of the cheese maturation chamber, respectively. Similarly, Lanita and da Silva (2008) determined that 60-day ozonation reduced the numbers of airborne yeasts and moulds by 63% in the air of a Parmesan-type cheese ripening room.

Based on the official opinion of the National Food Safety Committee (CNSA), the Italian Ministry of Health (2010) endorses the use of ozone for disinfecting empty cheese ripening and storage facilities. Interestingly, a British company has claimed that regular ozone treatments in cheese stores are even capable of eliminating mite damage (Ozone Industries 2003).

Wastewater treatment in dairy processing

Water plays a pivotal role in a wide range of operations, including cleaning, disinfection, cooling and heating, carried out in the dairy industry (Riedewald 2011; Norton and Misiewicz 2012). For this reason, dairy processing plants use huge amounts of water and, as a consequence, generate large quantities of wastewater, the latter being characterised by high organic contents (Assalin et al. 2004; László et al. 2007; Pascual et al. 2007; Rad and Lewis 2014; Packyam et al. 2015). Dairy wastewaters are conventionally purified with physicochemical and biological methods (Baskaran et al. 2003; László et al. 2007). Over the recent years, however, several researchers have tested ozonation, using it either alone or in combination with other technologies, in order to reuse, at least in part, the wastewater produced by the dairy sector.

Ozone treatment was employed by Loorits et al. (1975) to oxidise major components in a dairy effluent. Ozonation was shown to decrease the initial fat content of 80–230 mg/L by 96–98%, thereby enabling the lightly polluted effluent to be discharged into natural watercourses.

In more recent investigations, László et al. (2007, 2009) have also found ozone treatment to be a very promising method for reducing the concentrations of organic pollutants in dairy wastewaters. Owing to its microflocculation effect, ozonation increased the removal of COD from dairy wastewater samples during subsequent nanofiltration. In addition to this, the biodegradability of the pre-ozonated nanofiltration retentates was 40% (equalling 27.6 percentage points) higher than that of the untreated (i.e. nonozonated) retentate samples (László et al. 2007).

Similar observations were made by Sivrioğlu and Yonar (2015) in a study, wherein an iron sulphate (FeSO4)-based chemical coagulation method and advanced oxidation processes, including ozonation, were tested and compared as possible pretreatment alternatives for a high-strength dairy effluent, with 6300 mg/L of COD, prior to discharge to a biological wastewater treatment plant. Pre-ozonation trials were run with an ozone level of 2 g/h at pH values of 7–12. The highest COD removal rate (71%) was obtained in the effluent at pH 12 following a treatment period of 240 min. Ozonation proved to be a technically efficient but economically inefficient dairy wastewater pretreatment method compared with the FeSO4 coagulation process because the treatment costs, excluding the costs of sludge disposal and labour, were calculated to be €7.62/m3 and €0.42/m3, respectively.

In an attempt to enhance the efficiency of sludge disintegration, Packyam et al. (2015) applied a combined phase-separation method, involving ultrasonically induced deflocculation and cell lysis through ozonation, for the pretreatment of a dairy waste activated sludge characterised by soluble COD, suspended solids (SS) and total solids (TS) levels of 400 mg/L, 7000 mg/L and 12 560 mg/L, respectively. Under optimum operating conditions (76.4 kJ/kg TS of specific energy and 0.0011 mg O3/mg SS), the ultrasound-mediated ozone pretreatment resulted in considerably increased COD solubilisation and SS reduction percentages compared with single pre-ozonation, and it also enhanced the anaerobic biodegradation potential of the dairy waste activated sludge. However, it must be noted that the economic feasibility of this novel phase-separated sono-ozone pretreatment is questionable because, according to the authors’ calculations, the net cost of (i.e. loss on) a ton of sludge thus treated is $4.21.

Martins and Quinta-Ferreira (2010) studied the possibility of using ozone for oxidising biologically pretreated cheese whey wastewaters to obtain effluents dischargeable to natural aquatic systems. Single ozonation, especially at an alkaline pH of 10, substantially decreased the high organic content of cheese whey. The application of 16.5–33.0 mM of hydrogen peroxide (H2O2) further enhanced the efficacy of ozone treatment. It was therefore concluded that ozonation combined with the use of H2O2 could be a useful technology for the ultimate purification of cheese whey effluents after an activated sludge biological treatment, resulting in final streams to be disposed of in natural waterways.

Conclusions

Although several studies have been published on the application of ozone in food processing, to our knowledge, this is the first-ever systematic review of the use of ozone specifically in the dairy industry. Transition in milk production and processing from chlorine and other conventional disinfectants to ozone requires an in-depth understanding of the potential and limitations of ozonation. The clear and convincing communication of the overall benefits provided by this advanced, cost-effective and environmentally friendly technology is a prerequisite to widespread adoption and usage of ozone by the global dairy industry. Further research is needed to efficiently and safely utilise ozone and to find new applications for this powerful disinfectant in the dairy sector. Some of the key issues that researchers in the field should focus on include:

- Determining the optimum ozone dosages, contact times and other treatment variables for every single dairy application.

- Fully characterising the specific chemical and physical reactions taking place during the ozone treatment of dairy foods containing various levels of total solids.

- Designing and manufacturing advanced ozone-generating systems whereby purer ozone gas can be produced.

- Developing further combined methods involving ozonation, with particular attention being paid to the economic feasibility of such novel approaches.

- Clarifying the influence of ozonation on degradation of certain chemical contaminants, such as mycotoxins, in milk and dairy foods, and conducting toxicological tests to determine the possible effects of degradation products on human health.

- Thoroughly investigating the dose-dependent changes in structure and functionality of whey proteins during ozone processing.

- Assessing the positive and negative effects of ozone treatments on sensory properties of milk and dairy products.

Acknowledgements

Funds for compiling this article were provided by the National Development Agency of Hungary (Project No. GOP-1.1.1-11-2012-0457). The authors are grateful to Dr. Eszter Fördős-Gráczol of the University of West Hungary for her technical assistance.

More info on the use of ozone in dairy applications can be found on our website below: