OG-1000

OG-1000 Oxygen Generator will produce 1000 SCFH oxygen at 93% purity from 175 CFM compressed air at 45 PSI of pressure.

Call For Price

OG-1000 Oxygen Generator is an industrial oxygen concentrator great for continuous oxygen production. Compressed air must be supplied to the OG-1000. This compressed air is separated via Pressure Swing Absorption (PSA) technology. Oxygen is captured in a storage tank and can be supplied to the point of use at any flow rate required up to 1000 SCFH at pressures of 45 - 60 PSI.

Features:

Dependable:

OG-1000 Oxygen Concentrator is built to provide thousands of hours of continuous, reliable service. The Zeolite sieve is factory sealed in solid steel tanks and rarely needs replacement. With very few moving parts, our generators are built to provide thousands of hours of continuous, reliable service Routine maintenance is as simple as changing an air filter.

Durable

OG-1000 is built with precision-welded tank assemblies (ASME coded) and oxygen-clean brass tubing and valves which allow them to operate in extreme conditions.

Made in the USA

Every PLC-controlled generator is assembled and tested in our North Tonawanda, NY production facility.

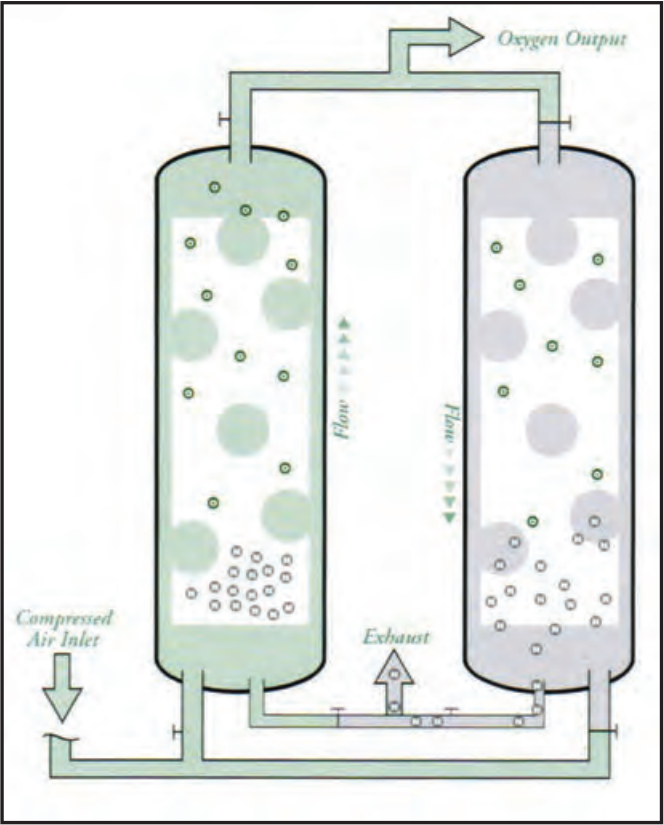

What is Pressure Swing Adsorption (PSA)

Clean, dry compressed air is fed into the first molecular sieve bed. Nitrogen is adsorbed, while oxygen is allowed to flow through. When the sieve in the first bed becomes full of nitrogen, the airflow is then directed into the second bed. As the second bed separates the oxygen from the nitrogen, the first bed vents its nitrogen into the atmosphere. Compressed air is once again fed into the first bed, and the process is repeated continuously. A constant flow of oxygen is reliably produced.

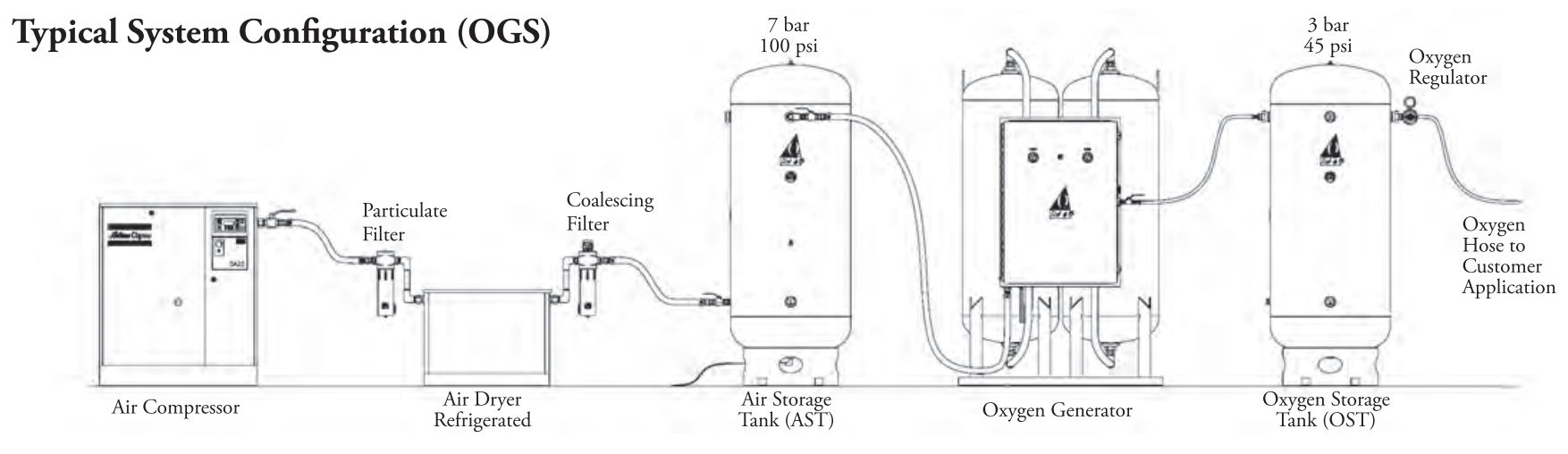

The OG-1000 Oxygen Concentrator requires compressed air for operation. Typical installation of entire system is outlined below.

-

Air compressor will provide at least 175 CFM compressed air at 90PSI or greater

-

Particulate filter will remove most dust, and oil from air stream

-

Refrigerant air dryer is used to remote moisture from air and provide 40-deg F dew point

-

Coalescing filter will remove any final oil mist and moisture from air flow

-

Air storage tank is necessary to provide sufficient air storage for oxygen generator purging

-

Oxygen Generator will purge nitrogen from air and capture oxygen

-

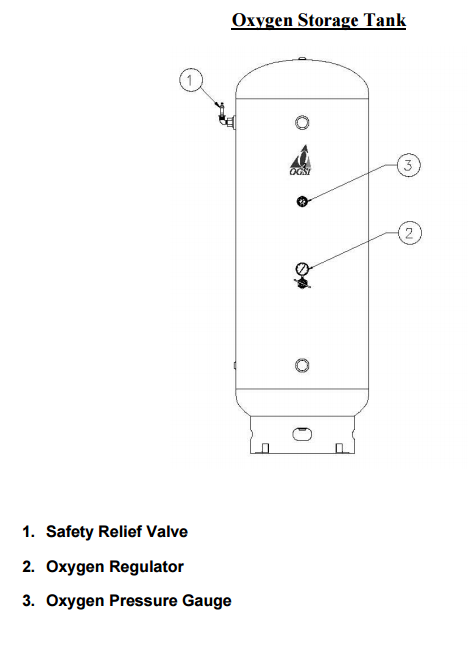

Oxygen storage tank will store oxygen and provide consistent oxygen flow and pressure to point of use

-

We also suggest installing an oxygen filter downstream of the oxygen storage tank to filter any zeolite dust from the oxygen concentrator

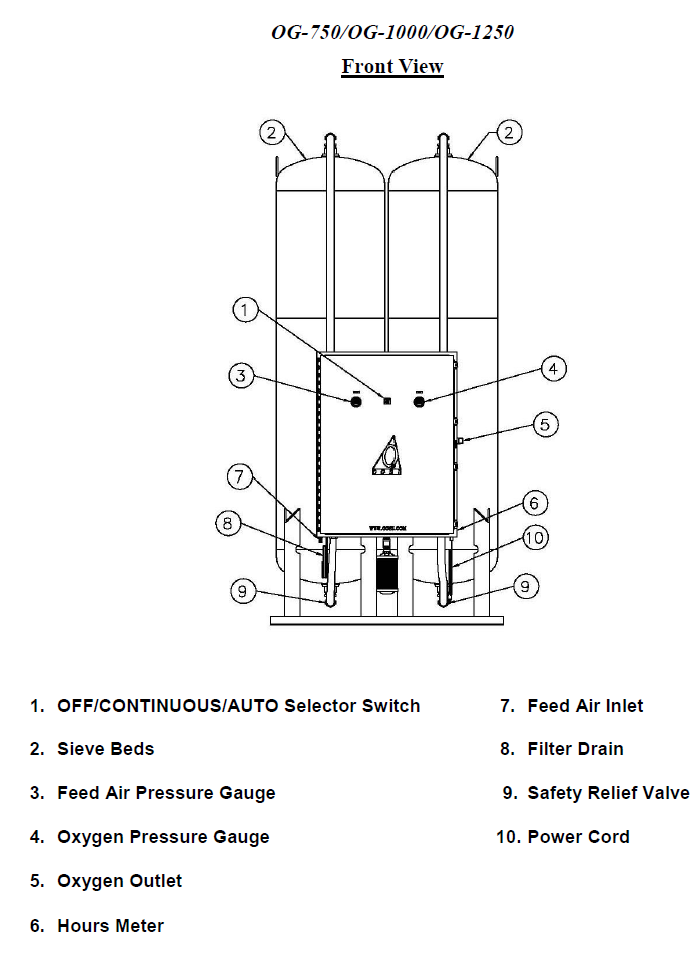

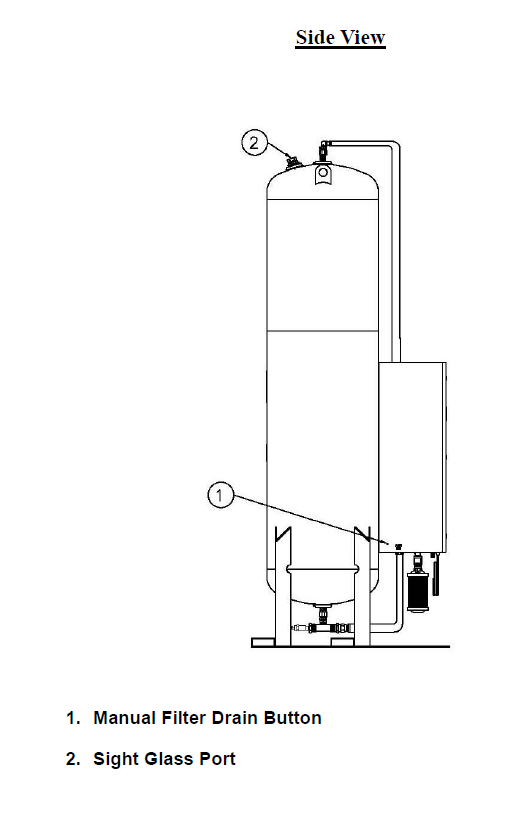

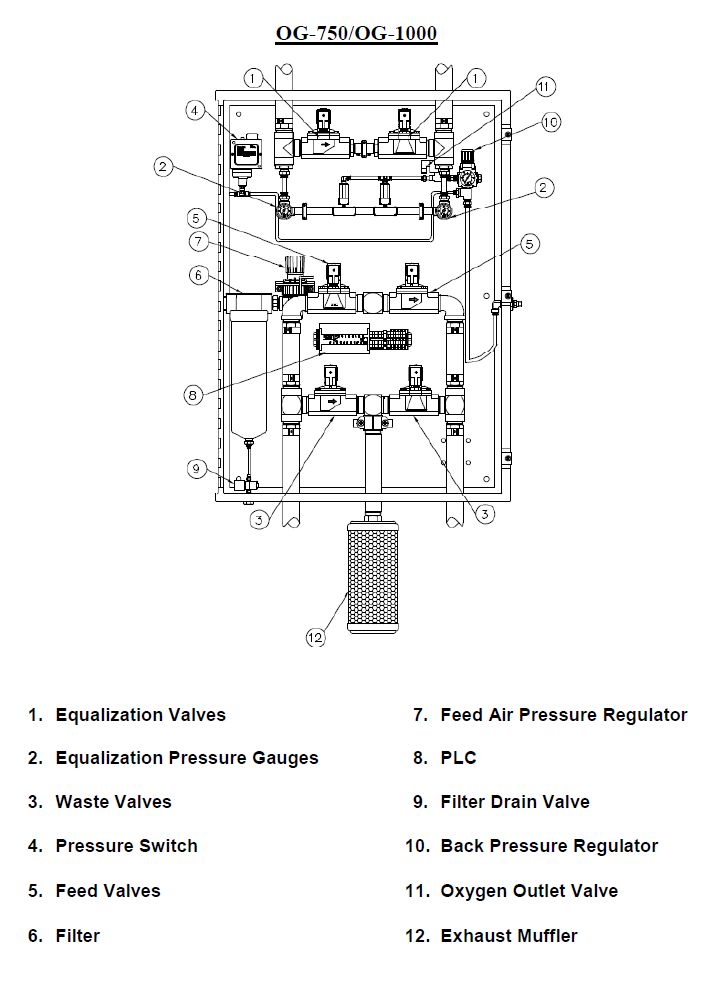

External components of the OG-1000 shown below. OG-1000 is a simple system to install and operate.

Control cabinet of the OG-1000 houses the PLC controller and all components. All components are simple and reliable. Every part on this oxygen concentrator is rebuildable or repairable. This is a machine that will serve your operation for as long as you wish.

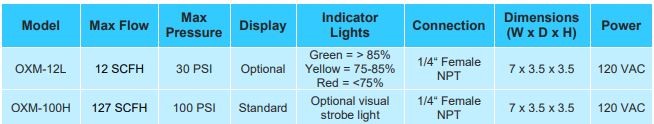

Optional oxygen purity switch can be added to the oxygen concentrator as an alarm. Simple oxygen purity monitoring. Provides relay contacts to alert of potential problems in your oxygen generation system. Max Flow Rate: 12 SCFH and Max Operating Pressure: 30 PSI.

Features

-

Powered and wired into oxygen generator

-

Oxygen plumbed through unit, no oxygen losses

-

Reliable ultrasonic sensor technology

-

Dual DPDT relay outputs, alarms triggered at > 85% O2 and > 75% O2 respectively.

-

Relay alarm for low oxygen purity

-

Analog or digital output

-

Optional LCD display

-

Optional remote monitoring

-

Optional visual strobe light

-

Optional audible alarm

Optional oxygen purity switch can be added to the oxygen concentrator as an alarm. Simple oxygen purity monitoring. Provides relay contacts to alert of potential problems in your oxygen generation system. Max Flow Rate: 127 SCFH and Max Operating Pressure: 100 PSI.

Features

-

Powered and wired into oxygen generator

-

Oxygen plumbed through unit, no oxygen losses

-

Reliable ultrasonic sensor technology

-

Dual DPDT relay outputs, alarms triggered at > 85% O2 and > 75% O2 respectively.

-

Integrated LCD display

-

Relay alarm for low oxygen purity

-

Analog or digital output

-

Optional remote monitoring

-

Optional visual strobe light

-

Optional audible alarm

Downloads:

| Manufacturer | OGSI |

|---|---|

| Call For Price | Yes |

| Listing Description | 1000 SCFH @ 45 PSI |

| Oxygen Production | 251 + SCFH |

| Internal Compressor | No |

| O2 Delivery PSI | 45+ PSI |

| Nominal Gas Flow Rate | 1000 SCFH |

| Operating Pressure | 45-60 PSI |

| Max Pressure | 65 PSI |

| Gas Connections | 1/2" Oxygen outlet, 1" air inlet Female NPT |

| Dimensions (LxWxH) | 55" wide x 48" deep x 121" tall |

| Operational RH Range | 0-85% humidity |

| Operational Temperature Range | 35 - 95-deg F |

| Power Requirements | 120 VAC, 60 Hz, 1-phase, 6amp (220 VAC optional) |

| Lead Time | 2-weeks |

| Warranty | 1 Year |

| Country of Origin | USA |

| Description | Requires 175 CFM air @ 90 PSI |