OXS Ozone Water System

OXS Ozone Water Systems will dissolve ozone into water for point of use applications, or water treatment applications where dissolved ozone in water is required.

Produce up to 100 g/hr of ozone from oxygen with integrated oxygen concentrator and ozone generator.

Call For Price

Call For Price

The OXS Ozone Water Systems produce up to 100 g/hr of ozone and introduces this ozone into water at up to 100 GPM. The OXS systems are designed for point of use (POU) applications where high levels of ozone in the water are required. This system can also be used for water treatment applications where lower dissolved ozone levels are required with higher water flow rates. For help with application information call our ozone experts, we would be glad to help.

System Features:

-One touch ON/OFF switch

-Ambient ozone safety sensor integrated in central controller

-CPVC piping is used for maximum ozone resistance

-Stainless steel ozone compatible pump

-Ozone produced from oxygen at high concentration

-Great mass transfer of ozone into water

-Capable of high dissolved ozone levels

-Compact design

Common Applications:

Specification Table:

| Model |

O3 Output | O2 Flow | % O3 | Water Tank | Max Water Flow | Ozone Dosage | Compressed air | Notes |

| OXS-10 | 10 g/hr | 8 SCFH |

3.5% | 20 Gallons | 30 GPM | 1.47 ppm @ 30 GPM 2.94 ppm @ 15 GPM |

4 CFM Required |

Air Cooled O3 Gen |

| OXS-20 | 20 g/hr | 15 SCFH |

3.5% | 20 Gallons | 30 GPM |

2.94 ppm @ 30 GPM |

4 CFM Required |

Air Cooled O3 Gen |

| OXS-30 | 30 g/hr | 15 SCFH |

4.5% | 30 Gallons | 50 GPM |

2.65 ppm @ 50 GPM |

4 CFM Required |

Air Cooled O3 Gen |

| OXS-40 | 40 g/hr | 20 SCFH |

4.7% | 40 Gallons | 50 GPM |

3.53 ppm @ 50 GPM |

4 CFM Required |

Air Cooled O3 Gen |

| OXS-60 |

60 g/hr |

30 SCFH |

4.7% | 50 Gallons | 80 GPM | 3.31 ppm @ 80 GPM 6.61 ppm @ 40 GPM |

8 CFM Required |

Water cooled O3 Gen |

| OXS-80 | 80 g/hr |

40 SCFH |

4.7% | 50 Gallons | 100 GPM | 3.53 ppm @ 100 GPM 7.05 ppm @ 40 GPM |

8 CFM Required |

Water cooled O3 Gen |

| OXS-100 | 100 g/hr |

40 SCFH |

6% |

50 Gallons | 100 GPM | 4.41 ppm @ 100 GPM 8.82 ppm @ 40 GPM |

8 CFM Required |

Water cooled O3 Gen |

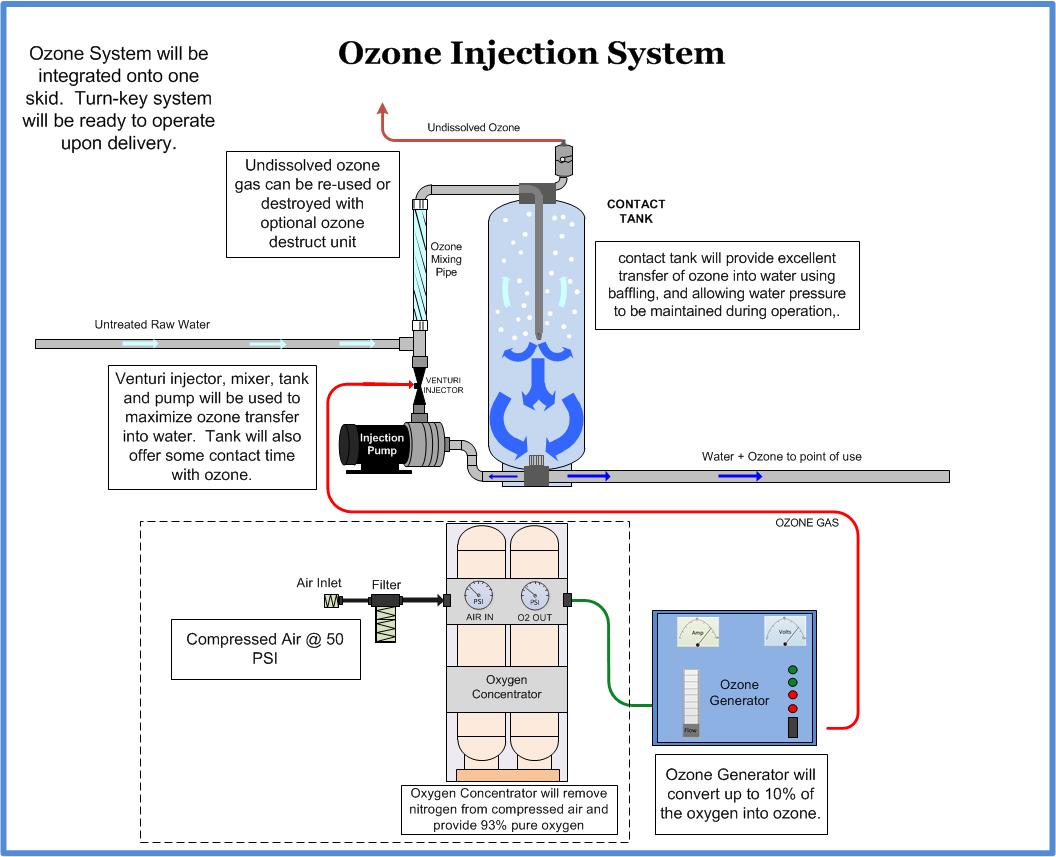

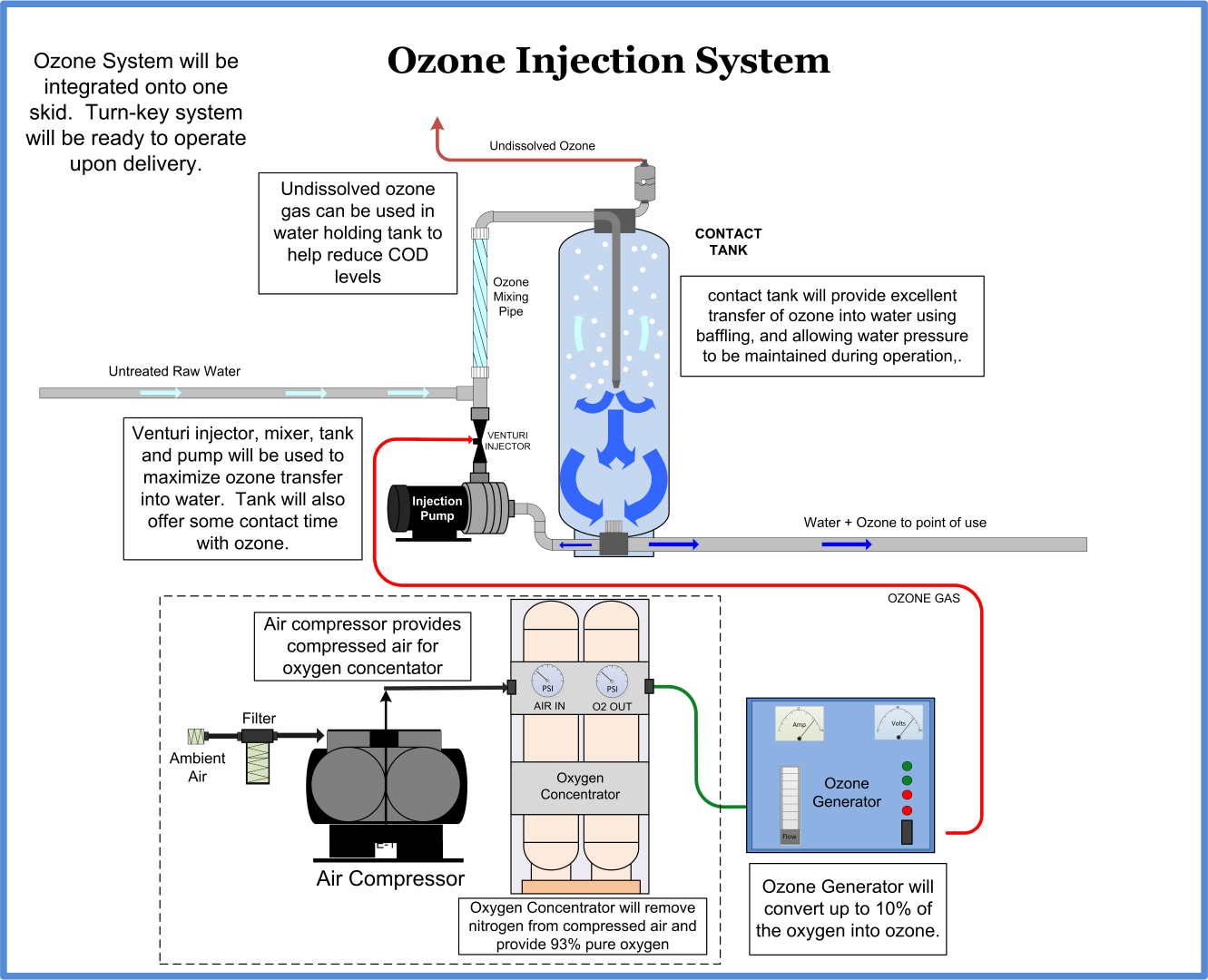

How it Works:

Ozone is produced via corona discharge with a high concentration Ozone Generator. Ozone is produced from oxygen that is provided with the integrated oxygen concentrator. Ozone and oxygen are pullled through the ozone generator, and into the water with a Mazzei venturi. The Mazzei venturi pulls ozone into water via vacuum and mixes this ozone efficiently with water. Water pressure differntial accross the venturi is prodcued with a stainless teel Grundfos water pump. The only moving part on this ozone system is the water pump.

Ozone is mixed with the water in the ozone contact tank. After the ozone gas is pulled into the venturi the water is further mised in a mixing pipe prior to entering the contact tank via a mixing diffuser. This tank will efficiently mix ozone gas with the water and provide excellent mass transfer of ozone gas with the water. All excess ozone will be off-gassed through the air vent on the top of the contact tank. Water will flow through the contact tank in a counter current flow from the ozone gas escaping from the tank. All process water must flow through this tank offering contact time with ozone and water and efficient mixing of ozone and water.

The Oxygen Concentrator on these systems requires compressed air for operation. This compressed air must be supplied by the customer from an external source with good clean, dry, compressed air. It is optional to include an internal compressor in the oxygen concentrator for convenience. Environment must be clean, and ambient air must be less than 85% humidity.

Optional Accessories:

The OXS Ozone Systems can be configured with a wide variety of optional accessories to custom tailor them to your specific application. For information about ozone systems for your application call our application engineers today for free consulting advice.

-Dissolved Ozone Monitor - will measure actual dissolved ozone levels in the water real time. The ozone system can be controlled to maintain a desired ozone level in the water, or alarms can be used to alert personnel when ozone levels are low.

-ORP Monitor - measures ORP (oxidation reduction potential) levels in the water real time. The ORP monitor can be used to ensure water treatment is effective and that the ozone system is functioning. While ORP is not a direct measurement of ozone in water it is a great tool to ensure the ozone system is providing the necessary water treatment.

-Ozone Catalyst Unit - catalyzes ozone safely back to oxygen to ensure any off-gassed ozone is not introduced into the air. Ozone Destruct unit is provided with an air trap and heater to ensure water does not damage the catatic material used.

-Remote Ambient Ozone Sensor - will measure ozone in remote location (point of use of ozon water) to ensure safe environment where the water is actually bieng used.

-Water Pressure Switch - can be used to turn ozone system ON and OFF based on water usage as measured by the water pressure switch. User settable

-Internal Compressor Options- The Oxygen Concentrator on these systems requires compressed air for operation. This compressed air must be supplied by the customer from an external source with good clean, dry, compressed air. It is optional to include an internal compressor in the oxygen concentrator for convenience. Environment must be clean, and ambient air must be less than 85% humidity.

Downloadable Content:

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | No |

| Ozone Output | up to 100 g/hr depending upon option |

| Feed Gas | Oxygen |

| Nominal Gas Flow Rate | See Spec chart for details |

| Operating Pressure | 20 - 30 PSI |

| Max Pressure | 50 PSI standard, up to 100 PSI optional |

| Operational Temperature Range | 35 - 95-deg F |

| Operational RH Range | 0-85% humidity |

| Power Requirements | 120 VAC, 60 Hz, 1-phase, 20-amp (220 VAC optional) |

| Lead Time | 2-4 weeks depending upon options |

| Warranty | 1 Year |

| Dimensions (LxWxH) | 24" wide x 22" deep x 55" tall - OXS-8 |

| Country of Origin | USA |