Characteristics of the MiCS-2610 Ozone Gas Sensor

Sponsored by SGX Sensortech

Table of Content

Introduction

Operating Conditions

Measurement Circuit

Heating Resistor

Gas Sensitivity

About SGX Sensortech (IS)

Introduction

The article discusses salient features and applications of the MiCS-2610 ozone gas sensor.

Basically the instrument can be used for determining the levels of ozone from an ozone-generating source within a building as well as for identifying dangerous concentrations of ozone in the air outside.

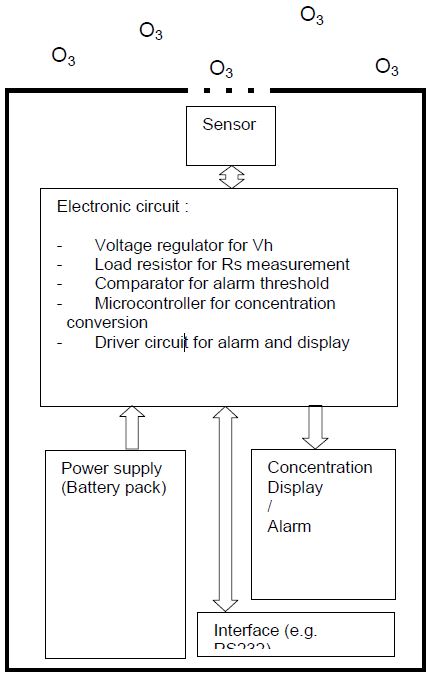

To prevent water and dust contamination of the sensing element, the sensor is placed inside a housing. By gas diffusion, ozone-containing air reaches the sensing element. When electric resistance is changed in the sensing layer, a voltage change occurs. The voltage change is utilized to determine an equivalent concentration of ozone with the aid of a microcontroller. The voltage can also be used to raise an alarm when the sensor’s voltage is compared with a pre-set threshold voltage (Figure 1).

Figure 1. Schematic of a portable ozone detection system with built-in alarm

Operating Conditions

The MiCS-2610 ozone gas sensor satisfies the specifications mentioned in Table below:

| Parameter | Symbol | Typ | Min | Max | Unit |

|---|---|---|---|---|---|

| Life time | tl | 5 | 5 | – | year |

| Switch on/off cycles | ncycle | 100’000 | 100’000 | – | – |

| Heating power | PH | 70 | – | – | mW |

| Relative humidity range | RH | 50 | 5 | 95 | %RH |

| Ambient operating temperature | Tamb | 20 | -40 | 70 | °C |

Measurement Circuit

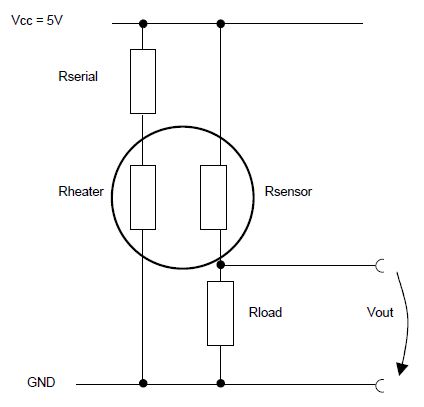

The sensor unit is provided with 5V power (Figure. 2). An 88Ω resistor Rserial is connected in series with a heating resistor Rheaterl so as to achieve a nominal heating power of 70mW.

RSl is calculated using the following formula:

RSl = RL /(VCC – VS) # x VS

Figure 2. Electronic circuit to power the heating resistor and to measure the sensing resistor

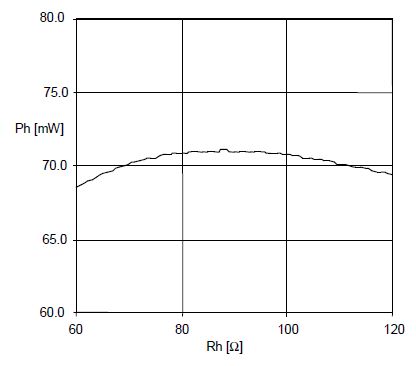

The changes occurring in the Rheaterl cause heating power variations, which are compensated by the simple circuit as shown in Figure 3.

For heating resistor values between 60 and 120Ω, the relative heating power variation is ±2 %.

Figure 3. Ph as a function of Rh. Rserial = 88 Ω and VCC = 5 V

Heating Resistor

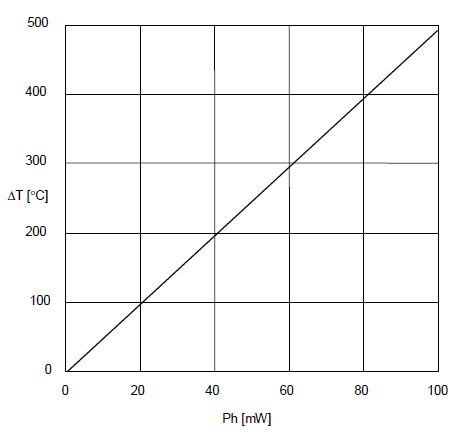

The sensing layer’s temperature is based upon both the ambient temperature and the heating power. It is ideal to maintain the sensing layer’s temperature within 350-400°C in order to gain quick response times and good sensitivity. When it goes below 350°C, sensitivity reduces thereby causing the sensor response to be much slower. Likewise when it goes above 475°C, the structure of the sensor can be damaged due to excess heat.

The graph (Figure 4) shows ΔT as a function of Ph where ΔT is the temperature increase and Ph is the applied heating power.

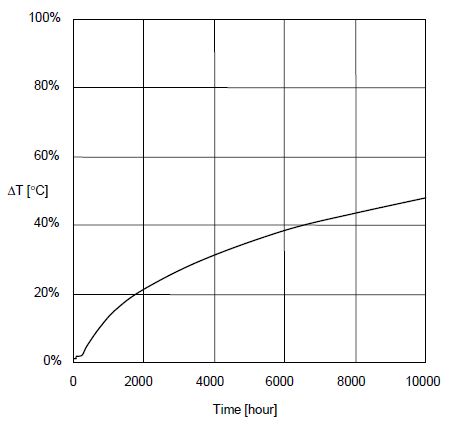

While in operation mode, the heating resistor gradually increases (Figure 5). However when a constant heater voltage is used, heating power decreases. If the power compensation circuit is constructed as per figure 2, loss of power can be limited. Around 40% of Rh increases after the 10,000h of operation, thereby resulting in less than 2% of heating power.

Figure 4. ΔT as a function of Ph

Figure 5. Relative increase of Rh as a function of power-on time at ambient temperature

Gas Sensitivity

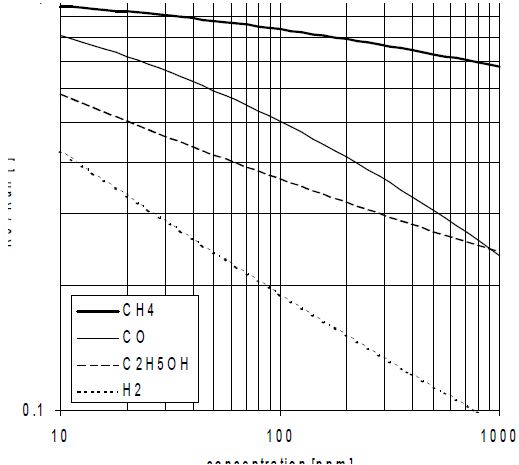

The graph (Figure 6) displays the sensitivity of the MiCS-2610 to CO, H2, ethanol (VOC), and CH4 (HC). Many interfering gases are known to be reducing gases that make the resistance to decrease; however ozone, which is an oxidizing gas, makes the sensing resistance to increase. The sensor’s resistance value varies with respect to humidity and temperature.

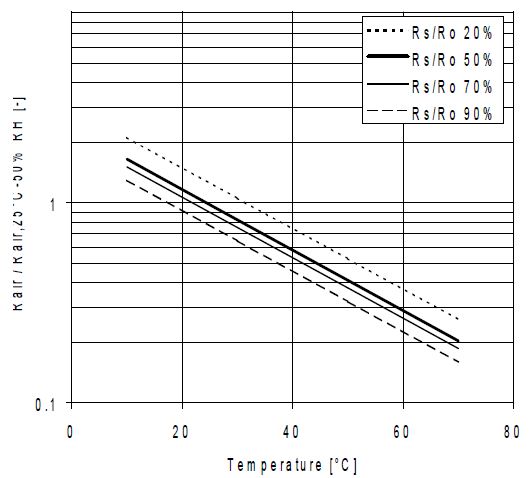

The gaseous form of water is humidity and reacts with the sensing layer similar to a reducing gas. When it is increased, there is a decrease in the sensing resistance. Similarly, temperature also behaves in the same manner as humidity. The negative temperature coefficient is because of the semiconductor properties found in the sensing layer material.

Figure 6. Sensitivity to CO, H2, CH4, and C2H5OH at 25°C and 50% Rh

Figure 7. Temperature dependence of baseline resistance Rair for 20%, 50%, 70% and 90% Rh

About SGX Sensortech (IS)

SGX Sensortech is a market leader in innovative sensor and detector devices that offer unrivalled performance, robustness and cost- effectiveness.

SGX have been designing and manufacturing gas sensors for use in industrial applications for over 50 years, offering excellent applications support for an extensive range of gas sensors and the expert capability for custom design or own label.

As an independent OEM supplier of gas sensors, we pride ourselves on providing customers with unrivalled product reliability and personal product support via specialist engineers.

SGX gas sensors are built to the highest standards with all pellistor and infrared gas sensors achieving ATEX and IECEx certification, SGX gas sensors are also UL and CSA approved.

Our product portfolio has continued to expand in technology and detectable gases used in a wide range of applications including:-

- Mining

- Oil and gas

- Confined space entry

- Indoor air quality

- Industrial area protection

- Leak detection

This information has been sourced, reviewed and adapted from materials provided by SGX Sensortech (IS) Ltd.