Decarbonize Your Waste Streams

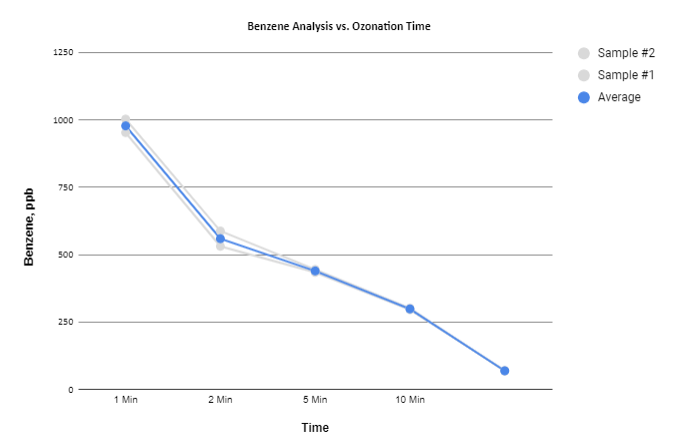

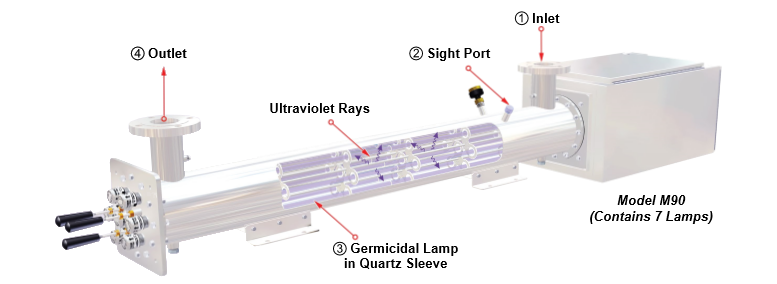

From, The Clean Waste Systems newsletter. Read original article HERE: https://www.linkedin.com/pulse/issue-2-september-26-2022-clean-waste-systems-llc/?trackingId=U1jpkjKTsiDkaHxZKHfgIw%3D%3D Clean Waste Systems manufactures medical waste disposal systems using ozone. This provides a cleaner, …