OG-15

The OG-15 is completely self-contained in a great looking powdercoated enclosure. It produces up to 15 standard cubic feet per hour (SCFH)/ 7.5 liters per minute (LPM) at up to 15 PSI, with oxygen purities up to 95%. The OG-15 built for 24 hour operation. The total industrial strength and quality of the OG-15 will provide the end-user with years of dependable, reliable, and virtually maintenance-free operation.

Durable

The OG-15 is built on a powder coated steel chassis. Its anodized aluminum sieve beds are fitted with custom molded composite end caps for years of reliable service. Weighing 78 lb (35 kg) the OG-15 is the industrial strength oxygen concentrator.

Safe

Why bother with the danger of high-pressure cylinder oxygen? The OG-15's built-in regulator allows you to set the delivery pressure according to your needs. The 0.3 hp compressor maintains an internal pressure of less than 9 psi, and delivers an optimal flow of oxygen up to 12 psi.

Economical

Oxygen is free! Eliminate the unnecessary costs of transportation, storage, and cylinder rental. The OG-15 uses less than 0.7 kW of electricity to deliver up to 15 standard cubic feet of oxygen per hour (SCFH). This product is cost effective and energy efficient.

Options Available:

230 VAC 50/60 HZ

No Cover

Anti-vibration Feet (for tabletop use)

Quiet Muffler Option

Pressure Switch and Relief Valve

Contact us for more details on each option

Simple to Use and Maintain:

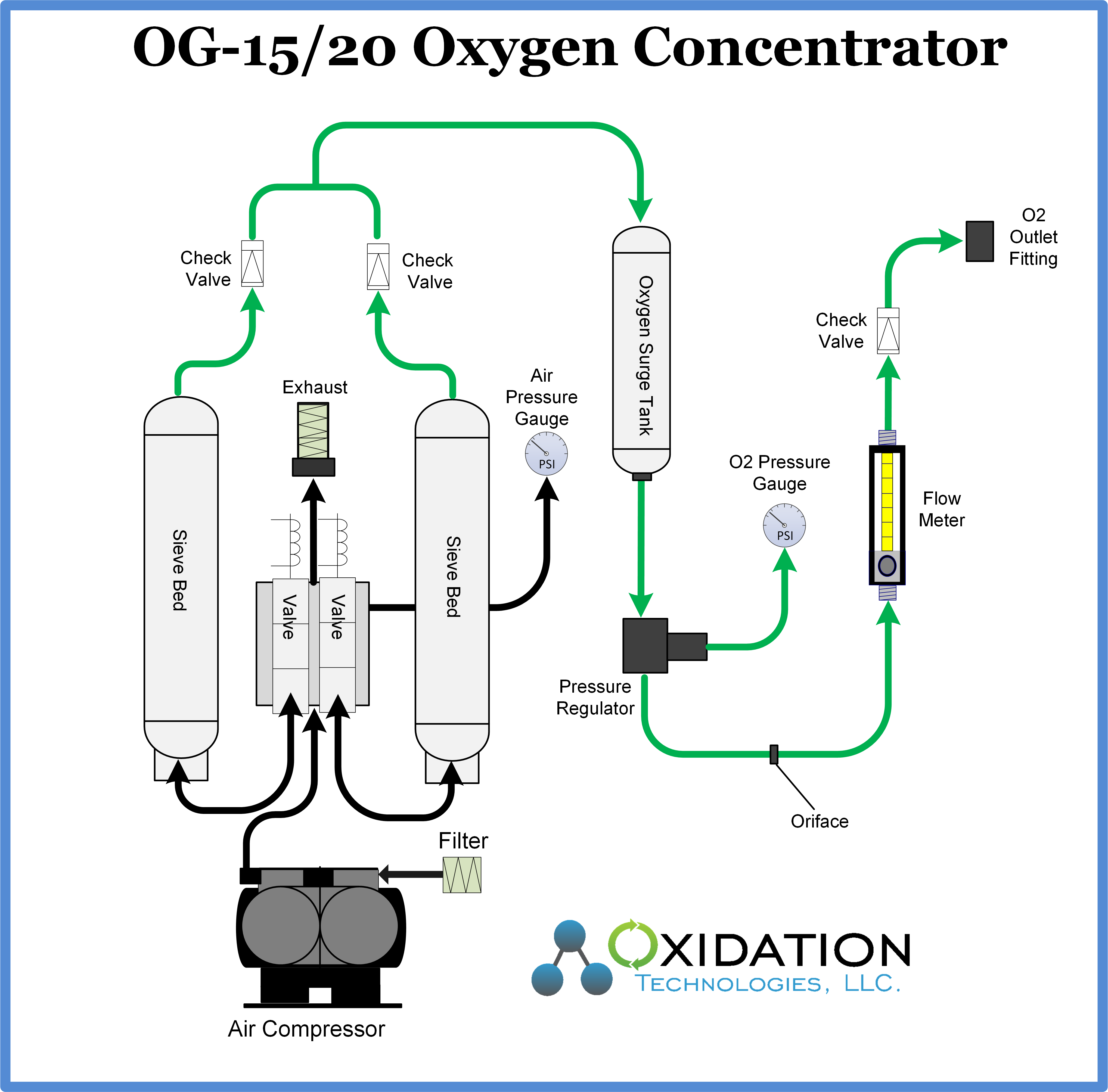

With a lighted on/off switch, integrated control panel, digital hours meter, custom flow gauges and controls, the OG-15 is truly user-friendly. Just plug it in, place the on/off switch in the “on” position, and set your oxygen delivery flow and pressure. The molecular sieve/zeolite (which separates the oxygen from nitrogen) is regenerative, and should not need to be replaced for the life of the unit under normal operating conditions.

Replacement Parts:

Replacement parts can be found on HERE.

OG-15 Inlet Air Filter Change:

OG-15 Sieve Bed Replacement:

Downloads:

| Manufacturer | OGSI |

|---|---|

| Call For Price | No |

| Listing Description | 15 SCFH O2 @ 12 PSI |

| Oxygen Production | 15 SCFH |

| Internal Compressor | Yes |

| O2 Delivery PSI | 15 PSI |

| Nominal Gas Flow Rate | 15 SCFH |

| Operating Pressure | 1-20 PSI |

| Max Pressure | 20 PSI |

| Gas Connections | 1/8" Female NPT connection (barbed fitting is supplied) |

| Dimensions (LxWxH) | 17" x 10" x 28" tall 43 x 26 x 71 cm |

| Operational RH Range | 0-85% humidity |

| Operational Temperature Range | 35 - 95-deg F |

| Power Requirements | 120 VAC, 60 Hz, 1-phase, 6amp (220 VAC optional) |

| Lead Time | 1-week |

| Warranty | 1 Year |

| Country of Origin | USA |

| Description | Turnkey unit with built-in compressor |