OST-20 Ozone Water System

The OST-20 Ozone Water System will produce 20 g/hr ozone and dissolve that ozone into water efficiently using a pump, venturi, mixing tank, and off-gas vent. All piping, enclosure, and system skid are constructed of stainless steel for maximum corrosion resistance. Options are available to customize this system to meet a wide variety of ozone applications where ozone dissolved into water is required.

Call For Price

The OST-20 Ozone Water System Produces 20 g/hr of ozone from oxygen and dissolves efficiently into water using stainless steel piping, pump, and skid for maximum corrosion resistance. The OST-20 produces 20 g/hr ozone and dissolves into water flows up to 30 GPM. This system is designed for point-of-use (POU) applications where high dissolved ozone levels are required.

The OST-20 is available with a wide variety of standard options listed, and available options to be customized to many ozone applications.

System Features:

- One-touch ON/OFF switch

- Automated system operation

- Ambient ozone safety sensor built-in

- All stainless steel piping with Sanitary tri-clamp connections

- Stainless steel enclosure houses all control and ozone generation equipment

- Stainless steel system skid

- Stainless steel ozone compatible pump

- Ozone produced from oxygen at high concentration for maximum ozone solubility into water

- Great mass transfer of ozone into water, capable of high dissolved ozone levels

- Mazzei venturi used to dissolved ozone into water

- Ozone output adjust 0-100%

- Remote start/stop control wiring built-in for system control

- Remote start/stop control wiring built-in for ozone generator control

- Panel mounted flow-meter indicates oxygen flow-rate through system

- Panel mounted pressure gauge indicates oxygen pressure

- Compact system design

Common Applications:

- Food processing

- Cooling Towers

- Bottled water

- Drinking water

- Ultra-pure water

- Surface sanitation

- Aquaculture

- Well water treatment

- Dairy applications

- Water reuse applications

Specification Table:

| Ozone Output: | 20 g/hr |

| Max Water flow-rate: | 30 GPM |

| Ozone Dosage Rates: |

2.94 ppm @ 30 GPM 5.88 ppm @ 15 GPM 8.82 ppm @ 10 GPM 17.64 ppm @ 5 GPM |

| Ozone Concentration: | 4% (nominal) |

| Oxygen flow-rate: | 8 LPM |

| Nominal oxygen concentration: | 93% (+/- 3%) |

| Water Connections: | 1.5" Sanitary (tri-clamp), 1" Female NPT available |

| Electrical power requirements: | 120 VAC, 20 amps (standard system, options may increase this value) |

| Compressed air requirements: | 4 CFM @ 50 PSI |

| Physical dimensions: | 24" wide x 24" deep x 80" tall |

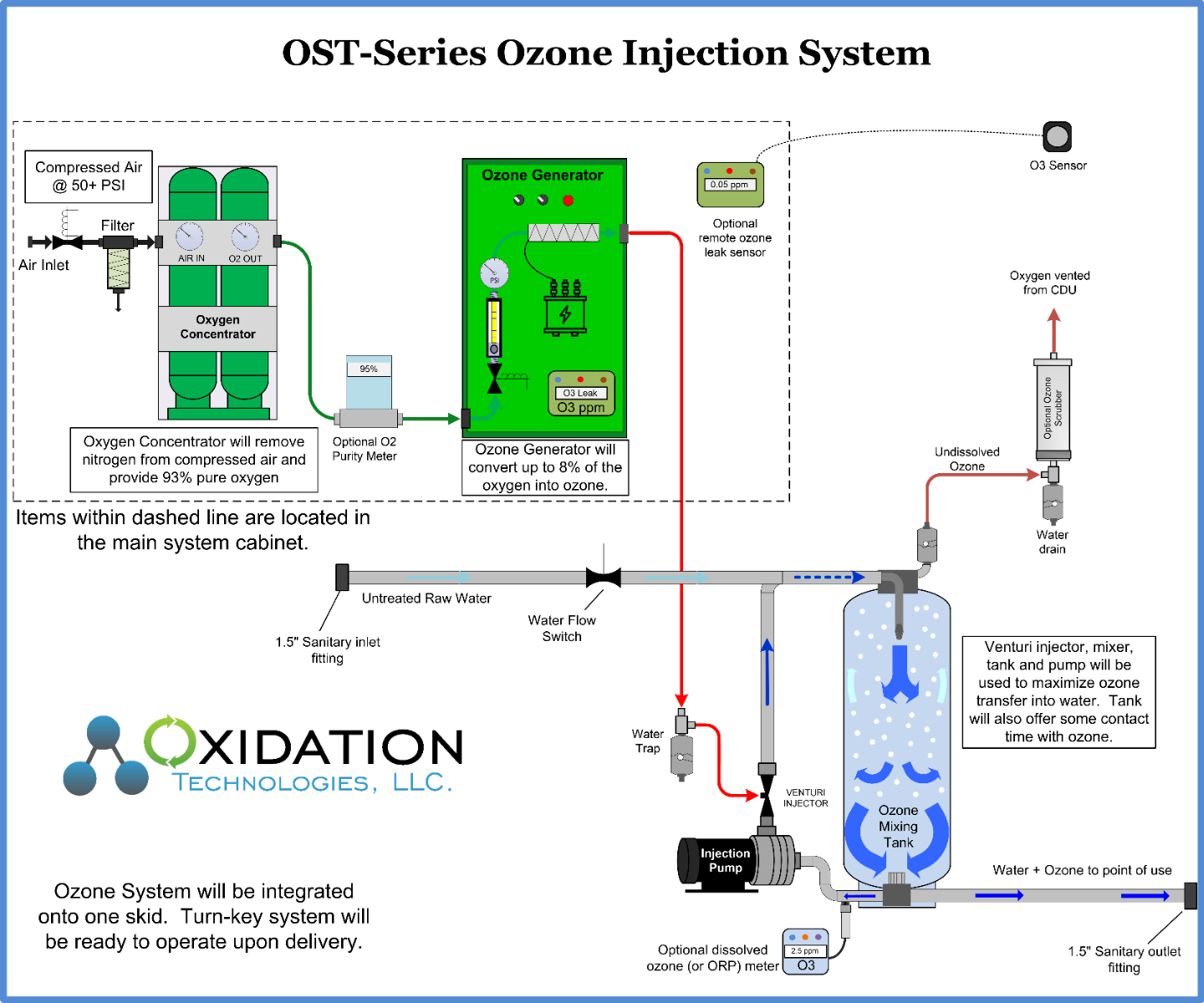

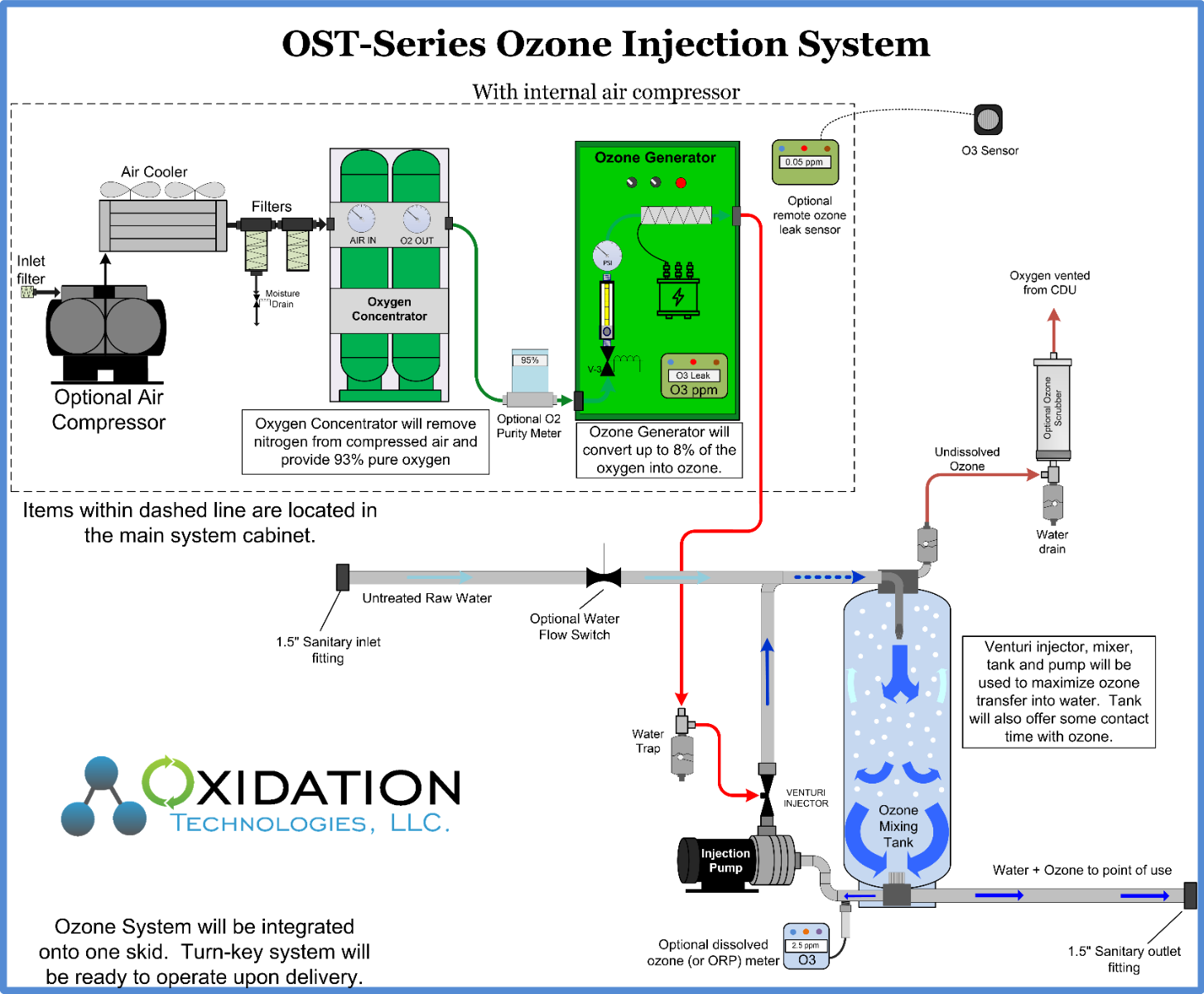

How It Works:

Ozone is produced via corona discharge with a high-concentration Ozone Generator. Ozone is produced from oxygen that is provided with an integrated oxygen concentrator. Ozone and oxygen are pulled through the ozone generator, and into the water with a Mazzei venturi. The Mazzei venturi pulls ozone into water via vacuum and mixes this ozone efficiently with water. Water pressure differential across the venturi is produced with a stainless steel ozone injection water pump.

Ozone is mixed with the water in our exclusive ozone contact chamber. The stainless steel ozone contact chamber is compact and efficient. Eliminating the large water tank saves cost, space, and makes a more efficient ozone system. This ozone contact chamber will efficiently mix ozone gas with the water and provide excellent mass transfer of ozone gas with the water. All excess ozone will be off-gassed through the air vent on the top of the ozone contact chamber. Water will flow through the ozone contact chamber in a counter-current flow of the ozone gas escaping from the tank. All process water must flow through this tank offering contact time with ozone and water and efficient mixing of ozone and water.

The Oxygen Concentrator on these systems requires compressed air for operation. This compressed air must be supplied by the customer from an external source with good clean, dry, compressed air. It is optional to include an internal compressor in the oxygen concentrator for convenience. The environment must be clean, non-condensing, and ambient air must be less than 85% humidity.

Optional Accessories:

The OST Ozone Systems can be configured with a wide variety of optional accessories to custom-tailor them to your specific application. For information about ozone systems for your application call our application engineers today for free consulting advice.

- Dissolved Ozone Monitor - will measure actual dissolved ozone levels in the water real-time. The ozone system can be controlled to maintain a desired ozone level in the water, or alarms can be used to alert personnel when ozone levels are low.

- ORP Monitor - measures ORP (oxidation reduction potential) levels in the water real time. The ORP monitor can be used to ensure water treatment is effective and that the ozone system is functioning. While ORP is not a direct measurement of ozone in water it is a great tool to ensure the ozone system is providing the necessary water treatment.

- Water Flow Switch - Turns the system ON/OFF based on water flow through the system, this is useful for POU systems and systems operated remotely from the water usage source.

- Ozone Scrubber, off-gas - catalyzes ozone safely back to oxygen to ensure any off-gassed ozone is not introduced into the air. Ozone Destruct unit is provided with an air trap and heater to ensure water does not damage the catalytic material used.

- Ambient Temperature Switch - Turns off ozone generation based on ambient temperature to protect the system from damage if operated in high ambient temperatures

- Relative Humidity Switch - Turns off ozone generation based on ambient relative humidity to protect the system from damage if operated in high humidity environments (only required for systems with a built-in compressor)

- Remote Ambient Ozone Sensor - will measure ozone in a remote location (point of use of ozone water) to ensure a safe environment where the water is actually being used.

- Ozone gas valve - Provides controlled ozone gas outlet for another application, such as room sanitation or cold storage. Can be used with a remote ozone sensor to control ozone levels in a room or space.

- Water Pressure Switch - can be used to turn ozone system ON and OFF based on water usage as measured by the water pressure switch. User settable

- Larger water tank- larger ozone mixing/contact tank available to provide engineered ozone/water contact time directly on this system. Tank sizes up to 250 gallons available.

- Internal Compressor Options- The Oxygen Concentrator on these systems requires compressed air for operation. This compressed air must be supplied by the customer from an external source with good clean, dry, compressed air. It is optional to include an internal compressor in the oxygen concentrator for convenience. The environment must be clean, and ambient air must be less than 85% humidity.

- Water Circulation Pump- Second pump is added to circulate water through an ozone injection loop. This ensures ozone water is fresh with little to no ozone level loss through a loop, or with long piping lengths.

The drawing below shows an OST-20 Ozone Injection System with the following options:

- Remote Ozone Sensor

- Ozone gas output valve

- Water flow switch

- Dissolved ozone sensor

- Water circulation pump

The image below shows the 11AV air vent and water flow switch

Each system uses the 11AV air vent to remove off-gassed ozone safely from the ozone mixing tank. This gas should either be vented to a safe location or pass through the optional ozone destruct unit.

This image also shows the optional water flow switch at the water inlet.

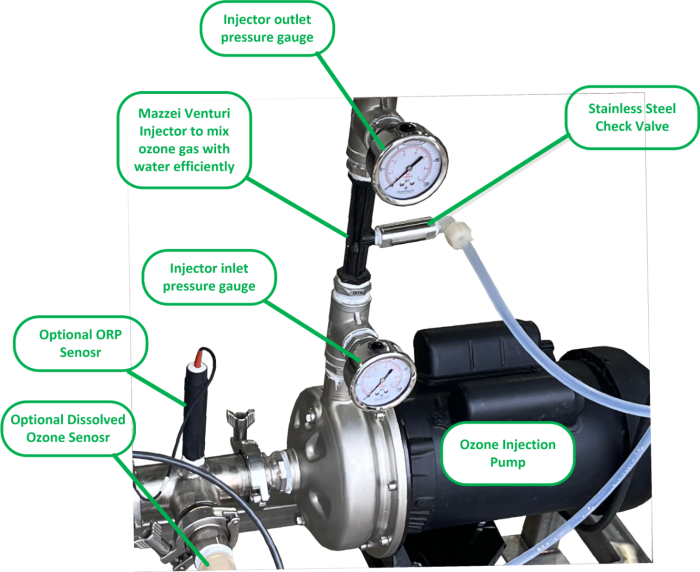

The image below shows the ozone injection pump.

Each system uses a Mazzei venturi to efficiently dissolve ozone gas with the water passing through the system. A stainless steel check valve is provided as an improved back-flow prevention device and ensures no ozone gas leaks at the venturi inlet port. Pressure gauges are installed to indicate venturi inlet and outlet pressures providing a great vidual indication of the function of the ozone system at a glance. This particular image also shows the physical location of the dissolved ozone sensor and ORP sensor.

Downloads:

- Examples of ozone systems with custom options can be seen HERE

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | Yes |

| Ozone Output | 20 g/hr |

| Feed Gas | Built-in O2 Concentrator |

| Nominal Gas Flow Rate | 10 SCFH |

| Operating Pressure | 30-50 PSI |

| Max Pressure | 50 PSI standard, up to 100 PSI optional |

| Operational Temperature Range | 35 - 95 deg F |

| Operational RH Range | Non condensing environment |

| Power Requirements | 120 VAC, 20 amps (standard system, options may increase this value) |

| Ozone Production | 20 g/hr |

| Lead Time | 6-8 weeks standard |

| Warranty | 1 Year |

| Dimensions (LxWxH) | 24" wide x 24" deep x 80" tall |

| Country of Origin | USA |