WT-10 Ozone Water System

The WT-10 is our smallest ozone injection system designed for residential Well Water treatment. System comes complete with all components necessary to produce 800 mg of ozone and dissolve it into water efficiently.

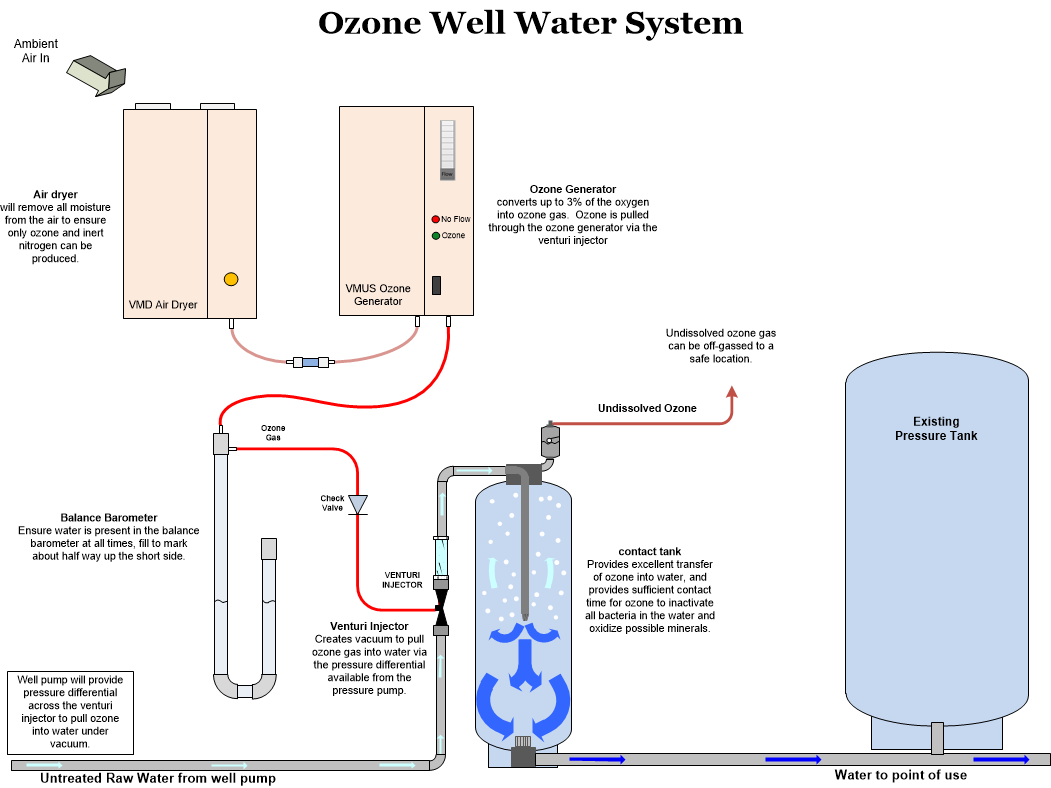

This system is perfect for water disinfection, H2S removal, and improving taste & odor issues. The WT-1 can also be used with the FIOX filter to provide additional oxidant for metals removal. Water flow rate and water test results are needed to determine system sizing and any filtration that may be needed. Typical installation set-up shown on diagrams below. Ozone system designed specifically for well water treatment. The WT-10 Ozone System is a complete kit that can easily be installed on any well water system with an existing well pump and bladder tank. We provide every component necessary for a complete well water treatment system. This system is perfect for water disinfection, H2S removal, removing taste & odor issues along with many other water quality issues.

Complete System Includes:

- Moisture Indicator

- Balance Barometer

- Ozone Contact Tank

| Iron Removal | < .1 ppm - requires FIOX filter for higher levels |

| Manganese Removal | < .1 ppm - requires FIOX filter for higher levels |

| Hydrogen Sulfide Removal | Up to 5 ppm |

| Pathogen Inactivation | 20 GPM continuous |

| Ozone Dosage | 5 g/h |

| Improve taste/odor | Yes |

| Service Flow Rate | 8 GPM |

| Peak Flow | 20 GPM |

| Backwash | 8 GPM |

| Filter Ag Plus | 1 CuFt |

See diagram below for details on entire system:

System Features:

- Complete kit comes with all major components

- Easy to install, typical DIY individual or handyman can install

- Easy to operate, completely automated

- Minimal maintenance, check monthly

- Chemical Free - ozone reverts to oxygen

- Great water quality at a low price!

Common Water Quality Issues Treated:

- Hydrogen Sulfide (H2S) oxidation

- Water disinfection, bacteria, coliform removal

- Total Organic Carbon (TOC) removal

- * Iron removal and filtration - requires the addition of filtration system

- * Manganese removal and filtration - requires the addition of filtration system

* Iron, Manganese, and other minerals can be oxidized with ozone but must be filtered from water for complete removal. Removal can be performed with back-washable filters, or simple media filters. Contact our office for details on filtration systems available or help sizing the right filters for your application.

System Operation:

System operation is outlined below.

An existing well pump and pressure tank (bladder tank) is required for operation of the ozone system. There will be a pressure switch on your system that will turn your well pump ON when water pressure in the pressure tank drops below your low set-point. The pump will then run until the high-pressure set-point in your tank is reached. The venturi injector and ozone tank will be installed in the water line prior to the pressure tank. As water is flowing through the venturi a pressure differential will be created across the venturi creating suction and pulling ozone gas into water. This will automatically pull ozone gas into the water and efficiently mix ozone in the water with the venturi injector.

The Ozone Generator will automatically turn ON when it detects a vacuum on the Ozone Generator. While your well pump is running and the venturi is pulling air through the Ozone Generator the Ozone Generator will automatically turn ON producing ozone. When the well pump turns OFF air flow will cease and the Ozone Generator will automatically turn OFF.

Ozone is produced via corona discharge in the Ozone Generator. A stainless steel corona cell with quartz glass dielectric is used. Air will pass through the corona cell at flow rates from 2 - 8 LPM, the oxygen in the air will be converted to ozone via the spark created in the corona cell. The Ozone Generator is air cooled with integrated fans. When the Ozone Generator turns ON the fans will also start and maintain a cool corona cell for reliable and consistent ozone production.

An Air Dryer is used to dry the air prior to entering the Ozone Generator. This will remove all moisture from the air to ensure the Ozone Generator operation is reliable and consistent. The Air Dryer uses moisture absorption desiccant that will absorb moisture from the air as it passes through the dryer. There are 2 tubes of moisture absorption desiccant, while one tube is drying air, the other tube is getting regenerated automatically ensuring reliable and consistent operation. A heater installed in each tube will heat the air dryer desiccant to vaporize the moisture and dry the desiccant automatically.

A balance barometer and check valve are provided with this system to ensure water cannot back-up from the venturi and damage the Ozone Generator. A balance barometer is a very simple device using water head pressure to balance the vacuum from the venturi and ensure ozone can be pulled into the venturi. However, if a failure of the system occurs and water backs-up from the venturi water will be pushed out of the balance barometer instead of backing up into the Ozone Generator.

The ozone contact tank supplied will allow the ozone gas to mix efficiently with the water. Mixer elements in the tank will mix ozone with water. Off-gassing of excess ozone will happen in the headspace of the tank with an air-vent. This will remove all excess ozone gas from the water efficiently. In applications such as H2S removal, TOC removal, or water disinfection the contact tank will allow time for oxidation of the contaminate, and off-gassing of the unwanted, oxidized by-products from the water.

Water with minimal ozone residuals will pass into your water system as normal. No extra parts, pumps, or moving parts are needed. The real advantage of this system is that it is automated, and no moving parts are added to your system. Your existing well pump works a little harder, and maybe a little longer to pull ozone into water. No other mechanical devices will be added to your system.

System Options:

Various options are available in the configuration set-up above. Follow the details below to determine the proper configuration for your application. Or, call our office for help. We would be glad to help you find the perfect system for your unique application.

Standard system is configured with the Model 684 venturi, 10 gallon tank, and no flash reactor.

Venturi Injector:

Choose the proper venturi using the chart below. Water flow-rate range is shown for each optional venturi size.

|

Venturi Model |

Water Flow-rate Range |

Thread size (NPT) |

| 584 | 4.5 - 6.3 GPM | 3/4" Male NPT |

| 684 | 7.4 - 10 GPM | 3/4" Male NPT |

| 784 | 9.5 - 13.5 GPM | 3/4" Male NPT |

| 878 | 7.8 - 11.1 GPM | 1" Male NPT |

| 978 | 9.1 - 12.8 GPM | 1" Male NPT |

| 1078 | 11.7 - 16.6 GPM | 1" Male NPT |

| 1583 | 23 - 32.5 GPM | 1.5: Male NPT |

For higher flow-rates a venturi by-pass can be installed with any one of the above venturi injectors.

Ozone Contact Tank:

The ozone contact tank is used to provide residence time for the ozone and water, and to off-gas excess ozone/air from the water after mixing. Higher water flow-rates may require a larger tank. Also, reduction of high levels of H2S or TOC may require additional residence time for complete oxidation. If you know what tank is best for your system, choose using the drop-down above. If not, please call our office, we would be glad to help.

Flash Reactor - Static Mixer:

An option on the system is a Mazzei flash reactor to be used as a static mixer in-line with the venturi injector. The Flash reactor will aid in mixing of ozone gas into the water prior to the contact tank. Choose the proper flash reactor based on water flow using the table below.

|

Flash Reactor |

Water Flow-rate Range |

Thread size (NPT) |

| 70-NK | 5.3 7.7 GPM | 3/4" Male NPT |

| 73-NK | 6.9 - 9.9 GPM | 3/4" Male NPT |

| 75-NK | 8.5 - 11 GPM | 3/4" Male NPT |

The flash reactor is not a required component for the system. Improved mass transfer efficiency of ozone gas transfer into water is achieved with the static mixer, in some applications a greater benefit will be realized with the static mixer.

How to Use the WT Controller:

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | No |

| Listing Description | 10 g/hr Well Water Treatment System |

| Ozone Output | 4 g/hr |

| Feed Gas | Dry Air |

| Nominal Gas Flow Rate | 8 LPM |

| Operating Pressure | NA |

| Max Pressure | NA |

| Operational Temperature Range | 35 - 95-deg F |

| Operational RH Range | 85% max |

| Power Requirements | 120 VAC 60 Hz |

| Ozone Production | 4 g/hr |

| Lead Time | 1-week |

| Warranty | 1 Year |

| Country of Origin | United States |