Back Flow Preventer

The BFP-SS Back Flow Preventor is designed to protect your valuable ozone generator from damage by water entering the ozone generator. Every ozone water system that generates ozone gas to be dissolved into water has a risk of water backflow into the ozone generator output. The BFP-SS Back Flow Preventer is an excellent comprehensive solution to solve this problem.

The BFP-SS Back Flow Preventer uses check valves and a Stainless Steel water trap to drain any water that does flow toward the ozone generator.

Part # BFP-SS

Use the BFP-SS Back Flow Preventer whenever you use an ozone generator to dissolve ozone into water to actively block, trap, and drain water that could potentially damage your Ozone Generator.

This Back Flow Prevention unit is designed to keep your Ozone Generator safe, by taking the water that backs up from you venturi and actively trapping and draining the water. It comes with a bracket that allows you to easily add to your Ozone System.

Two check valves are integrated with the 11AV water trap. A Stainless Steel Check Valve, CHK-6SV is used on the outlet of the BFP-SS, while a CHK-4k Kynar Check Valve is used on the inlet side of the BFP-SS. This intended design is to block water back-flow with the stainless steel check valve. If/when that check valve fails, the 11AV water trap will trap and drain any excess water while the Kynar Check Valve will prevent large volumes of water that build-up from backing into the ozone generator. This system will actively, block, trap, and drain water to protect your ozone generator in every ozone injection application.

BFP-SS Back Flow Preventer Instructions

- Inlet Connection: 3/8" compression fitting

- Outlet Connection: 3/8" compression fitting

- Drain Connection: 1/4" barbed fitting

Important of Back Flow Protection in Ozone Systems:

The BFP-SS Back Flow Preventor offers suburb protection in most every ozone system application. Below are example applications for installation

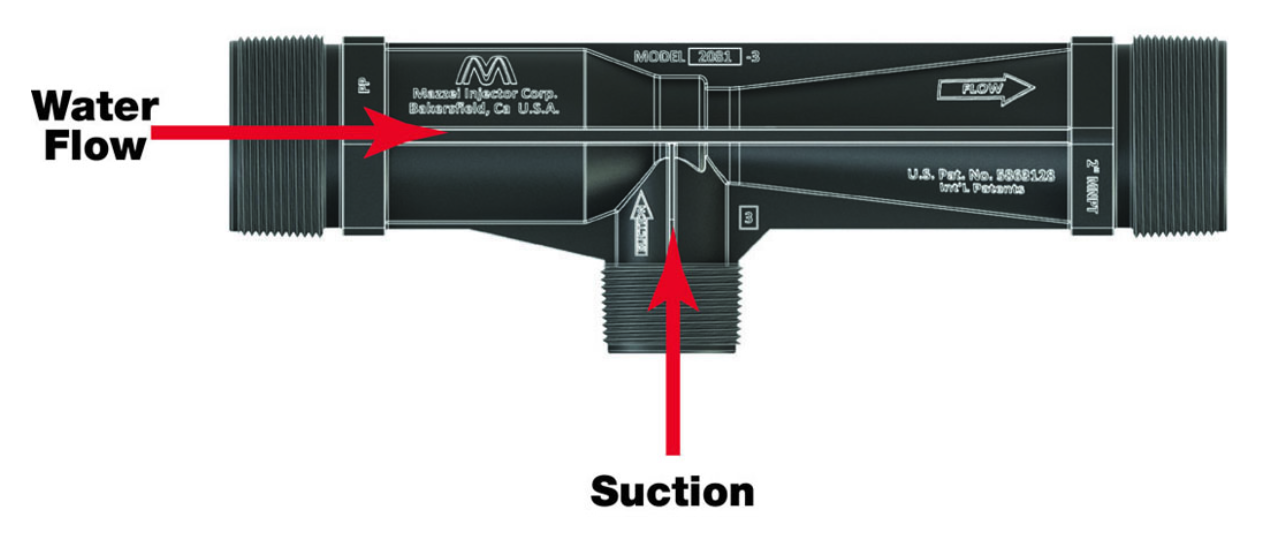

Vacuum driven ozone system with Venturi Injector

The image below shows the BFP-SS Back Flow Preventer used with a simple ozone generation system using a vacuum-driven ozone generator and air dryer. The Venturi Injector is used to produce suction/vacuum to pull ozone gas from the air dryer, through the ozone generator and into the water through the Venturi Injector.

When water flow through the venturi stops, suction on the ozone line also ceases. This will cause water pressures to exist on the suction port of the venturi injector. In this scenario, water may flow from the venturi, toward the ozone generator.

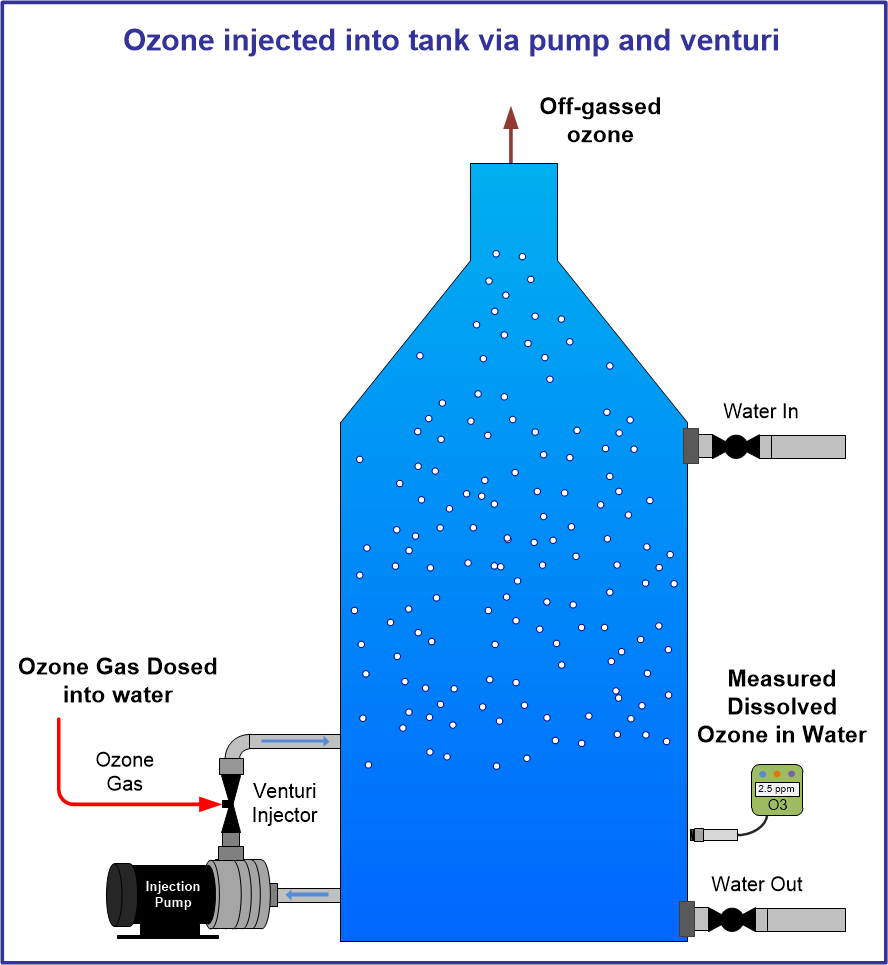

Pressurized ozone generator used with venturi or static mixer

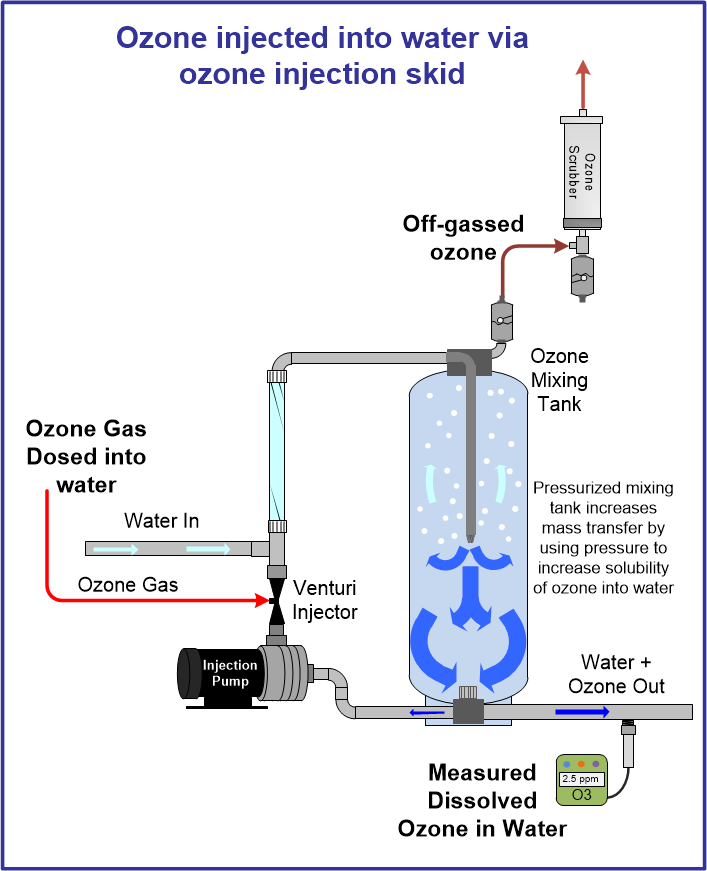

The image below shows a more complete system using an ozone generator producing ozone from oxygen under pressure. This oxygen/ozone gas is pushed, under pressure, toward the venturi injector. However, in some cases ozone/oxygen gas pressure can overcome water pressures and push gas into the water, under pressure to be mixed later with a static mixer.

In the scenario shown below, when the ozone injection pump turns OFF, the head pressure of the water tank will push water out the ozone injection point and toward the ozone generator.

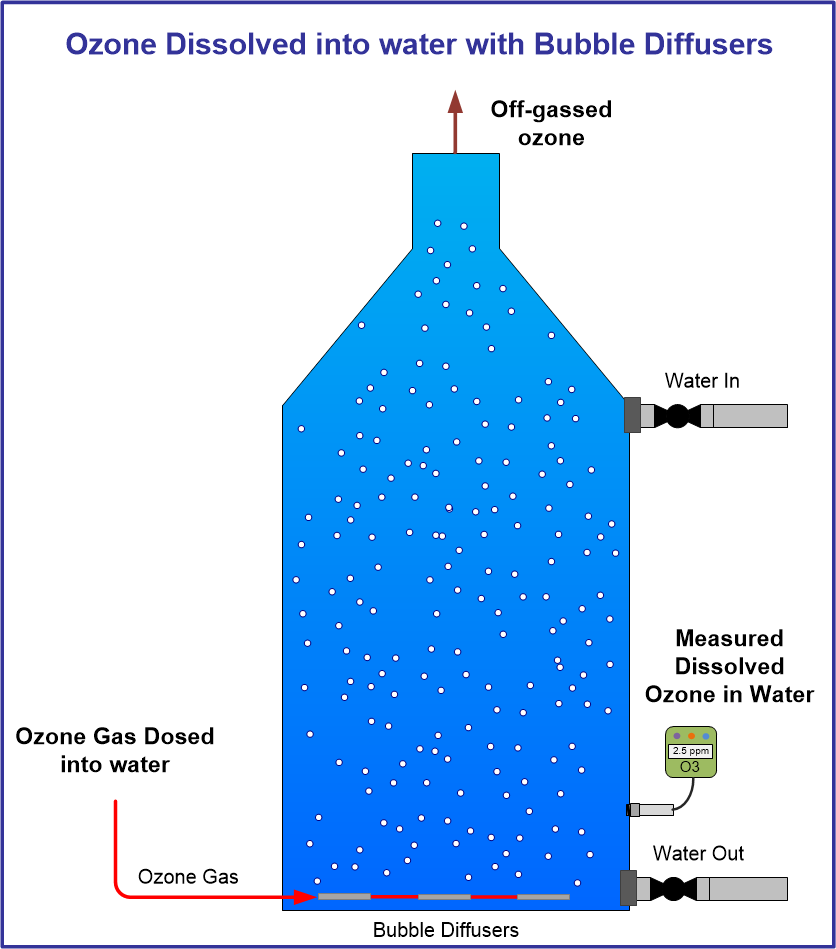

Pressurized ozone generator used with fine pore bubble diffusers

The images below shows a simple system where ozone gas is produced from oxygen under pressure and pushed to a fine pore bubble differ to bubble ozone gas into water and dissolving into water.

In this system, when the oxygen concentrator is turned OFF, or fails, water height from the tank will push water slowly, toward the ozone generator. This type of system is one of the most difficult to protect against water back-flow as the water pressure is low causing the check valve to not seat properly and slowly leaking water toward and into, the ozone generator. These systems may use oxygen concentrators and ozone generators with limited pressure capability due to the low pressures needed to push ozone/oxygen through the diffuser. Due to this, a high crack pressure check valve may not be suitable.

If you are using a bubble diffuser to bubble ozone into a water tank, take extra precaution to prevent water back-flow into the ozone generator.

Two additional considerations when using ozone bubble diffusers in tanks.

- We have seen some installs use an ozone gas line that rises above the tank, then drops to the tank in the hopes that this tubing height breaks the pressure from the tank. However, in upset conditions when the tank pressure rises slightly due to venting issues, or other upset conditions, this tall tubing loop becomes a very effective siphon delivering water very efficiently directly to the ozone generator.

- Mounting the ozone generator above the water height is a great consideration. In those cases ensure the tank is vented well with no potential vent failures. A very slight water pressure in the tank due to poor venting, while the tank is filling, may cause water to push toward the ozone generator.

Additional Information on Ozone System Design Below:

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | No |

| Nominal Gas Flow Rate | 30 LPM |

| Operating Pressure | 0 - 34 bar |

| Max Pressure | 34 bar @ 38-deg C |

| Gas Connections | " NPT inlet, " NPT outlet |

| Dimensions (LxWxH) | 1.5' tall 7" wide |

| Operational Temperature Range | 0 - 95-deg C |

| Power Requirements | none |

| Lead Time | in stock |

| Warranty | 1 Year |

| Country of Origin | USA |