Venturi 784 Black

Kynar PVDF Mazzei Venturi injector for ozone injection into water. Model 784, for water flows from 7.5 to 20 GPM.

Model 784 Venturi Injector uses 3/4" Male NPT connections inlet and outlet. Venturi is made from Black Kynar (Polyvinylidene Fluoride) material for maximum ozone resistance resulting in longevity on all ozone systems. For other materials, including stainless steel please contact us.

The Mazzei venturi injector is the most widely used method of dissolving ozone gas into water, and, for good reason. This is the most efficient and simple method to get ozone gas to dissolved into water.

Most ozone injection systems will use a Mazzei venturi to dissolve ozone into water. If you are replacing a venturi injector check the center of the bottom of the venturi (below the suction port) for a part number. It will be 3 or 4 numbers long. If you cannot find this, or if you are building your own system and need help sizing a venturi, please give us a call.

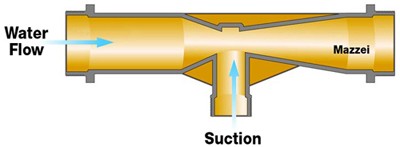

Venturi Injectors use a pressure differential of the water to pull ozone gas into the water. Using internal mixing vanes, water and gas are further mixed in the outlet of the venturi.

How a Venturi Injector Works:

Click HERE to see a video on how the venturi injector works

A venturi injector pulls ozone/oxygen gas into the water stream under a vacuum and dissolves that ozone/oxygen gas into water very efficiently. A pressure differential across the orifice in the venturi creates a high-velocity jet stream of water. This high velocity of water results in a decrease in absolute pressure and creates a vacuum on the third leg, or gas suction let. This gas is quickly and efficiently dissolved into the water directly after this Venturi.

Ozone/Oxygen gas is pulled into the water. The gas fills the void created by the suction action of the venturi to entrain the gas bubbles into water very efficiently.

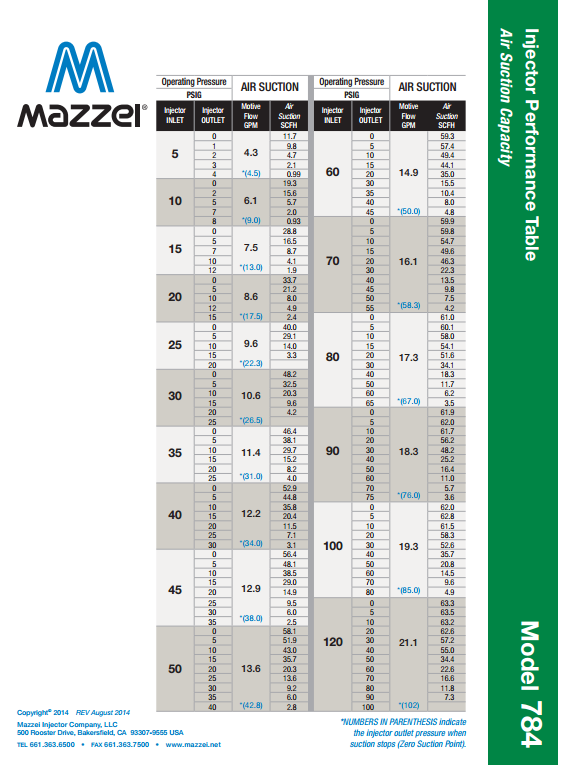

Venturi Injector Performance:

A venturi injector will operate over a wide range of pressures and water flows, however, each ozone injection application should be evaluated to ensure the right injector is chosen for your specific application. Below is a performance chart for air/ozone suction into water based on water flow and pressure on the venturi.

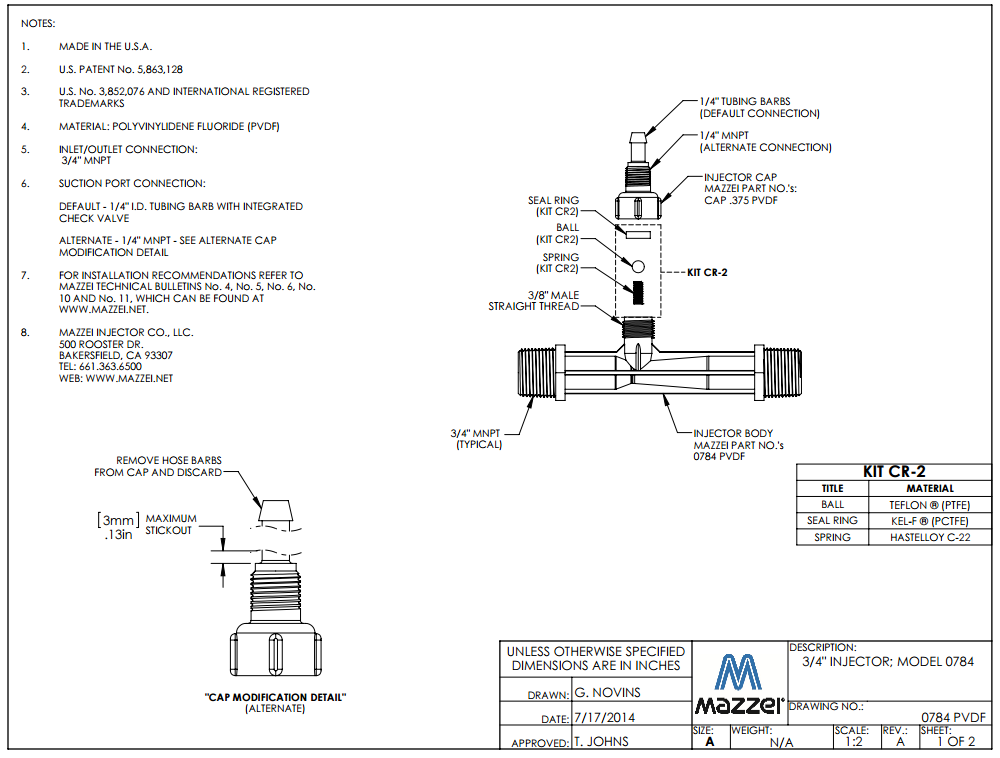

Diagram of Mazzei Venturi Injector Parts:

The Mazzei Venturi Injector is sold with an integrated check valve assembly. The parts used are all ozone resistant and will hold up to both ozone and hydrogen peroxide injection into water quite well. There is a barbed connection on the end of the check valve assembly to connect tubing to. Also, there is a threaded section that can be used for a threaded connection by cutting the barb off the fitting. This is a great option for a more leak-proof connection.

Tech Tip:

When we install venturi's on systems we remove the entire check valve assembly and thread a stainless steel check valve directly to the threaded body of the venturi. This eliminates the entire check valve assembly provided by Mazzei. We have found these to be failure prone, along with a light duty plastic threaded connection that can leak over time. By using a stainless check valve both potential ozone leaks and backflow to your ozone generator are prevented.

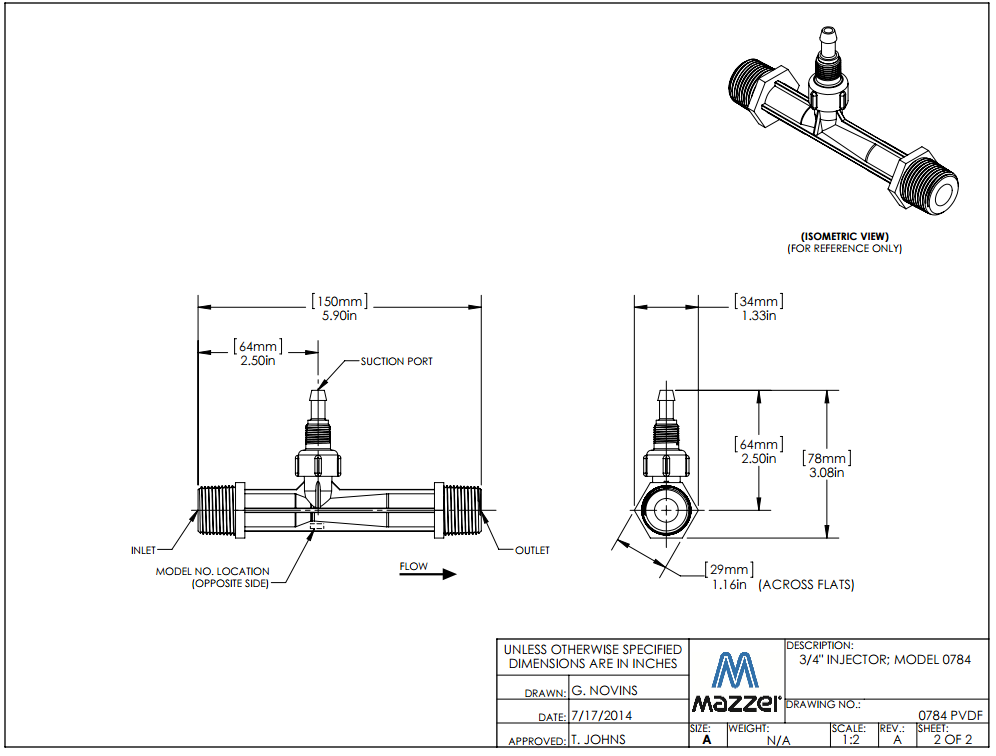

Mazzei Venturi Injector Dimensions:

Check Valve:

The Mazzei venturi injector is supplied with an integrated check valve. However, in our ozone applications, we remove this check valve and replace with a stainless steel check valve. The standard check valve supplied with a Mazzei venturi is a Kynar material that does not always create a leak-proof connection. The standard Mazzei check valve will also leak water slowly past the seal in many situations. By removing the stock check valve and threading this check valve directly on the Mazzei venturi a more secure connection is possible with stainless fittings, and a positive check valve with a positive seal is used.

Click HERE for Mazzei's recommendations on supplemental check valves

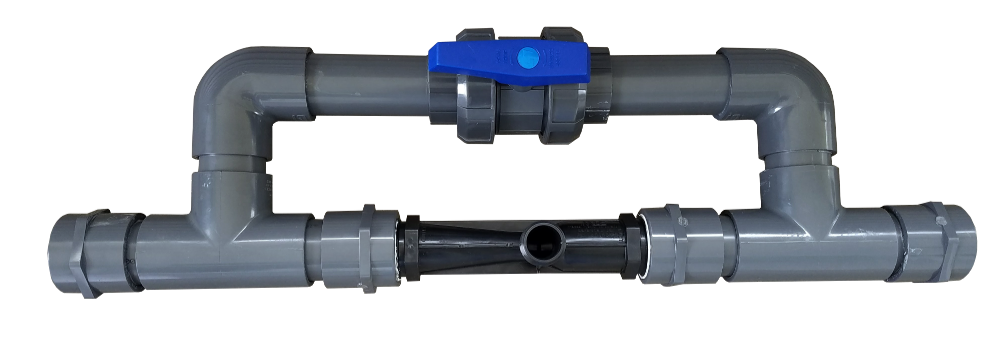

By-Pass Assembly:

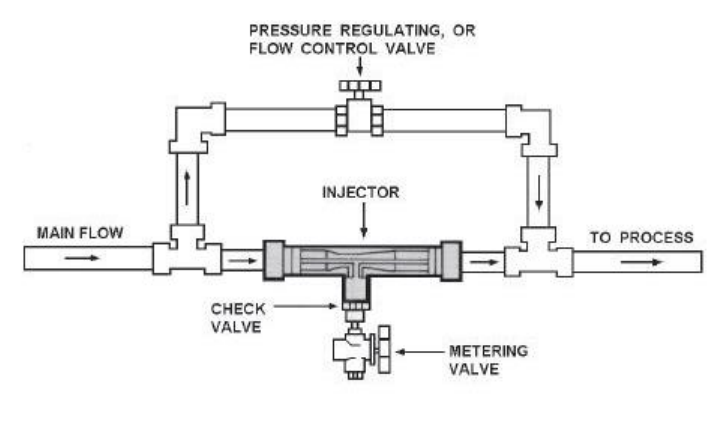

Installing the venturi injector into a by-pass assembly is suggested in some applications. When total flow rates of water are greater than the venturi chosen can handle a by-pass may be required. Also, if the specific suction and water flows are unknown the by-pass will allow for some flexibility in the venturi operation. See image below for details on a by-pass assembly.

Click HERE for By-Pass Installation bulletin

If required a by-pass assembly can be provided with your venturi purchase.

Ozone Solubility Information:

-Fundamentals of Ozone Solubility

-Bubble Diffuser to Dissolve O3

-Venturi Injector to Dissolve O3

Tech Notes:

-Complete Mazzei Venturi Injector Performance Tables (all mazzei venturi's are in one table)

-Tech Note - Injector Troubleshooting Guide

-Tech Note - Injector Ozone to Water Mixing

-Tech Note - Correction Factor for Gas Flow When Gas is Under Pressure

-Tech Note - Injector by-Pass Assembly

-Tech Note - Supplemental Check Valves

-Tech Note - Handling Solids During Injector and Nozzle Mixing

-Tech Note - Installation Notes

-Tech Note - Pressurized Sprinkler Applications

-Tech Note - Pressurized Water Line Applications

-Tech Note - Removal of Hydrogen Sulfide by Aeration

-Tech Note - Removal of Iron and Manganese by Aeration

-Tech Note - Water-Well/Pressure Tank Applications

| Manufacturer | Mazzei |

|---|---|

| Quickbooks Stock Level | 12.000000 |

| Call For Price | No |

| Typical Water Flow | 7.5-20 GPM |

| Thread Size | 3/4" Male NPT |

| Max Pressure | 150 PSI |

| Material of construction | Black Kynar |

| Lead Time | on hand |

| Dimensions (LxWxH) | 5.9-inches long x 1.33-inches wide x 3.08-inches tall |

| Country of Origin | USA |