ORK-15 Ozone Kit

15 lb/day Modular Ozone System designed specifically for Soil and Groundwater Remediation applications. Modular kit comes comlete with all components necessary for a complete remediation system to be installed in your trailer, shed, cargo container, or existing structure.

Call For Price

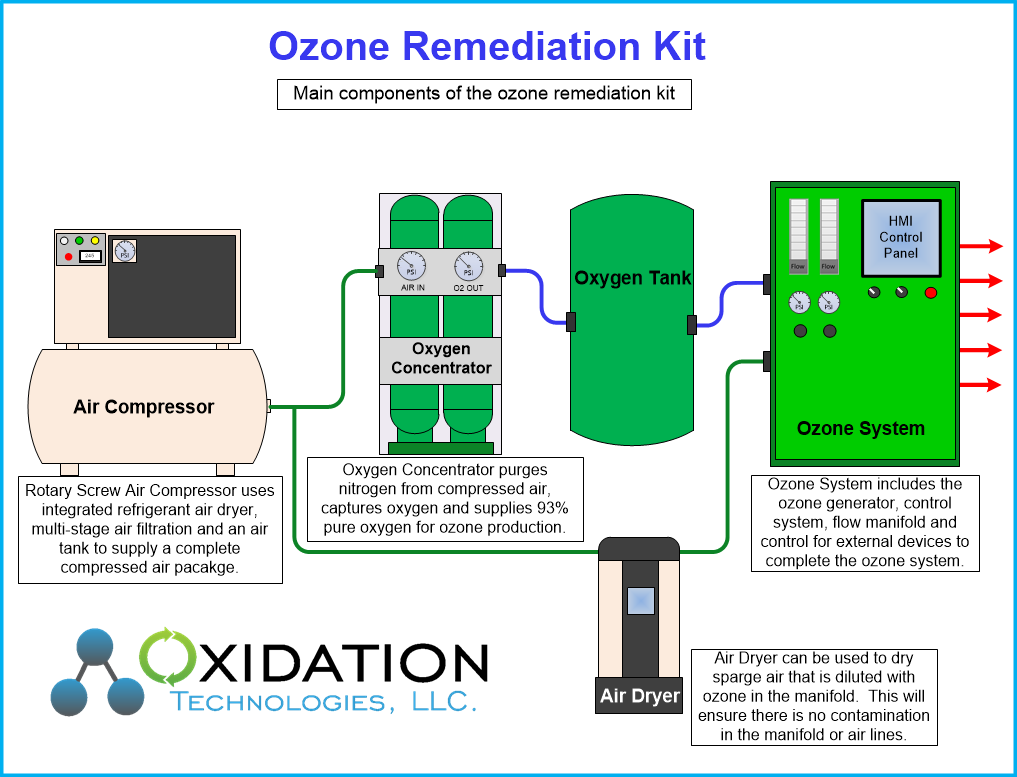

Modular ozone system is provided as a complete kit that is designed to be installed directly into the customer's existing enclosure. These systems are perfect for building an ozone remediation trailer, shed, or cargo container. The system could also be installed in an existing building or in existing remediation equipment trailer to supplement a current system with ozone chemical oxidation.

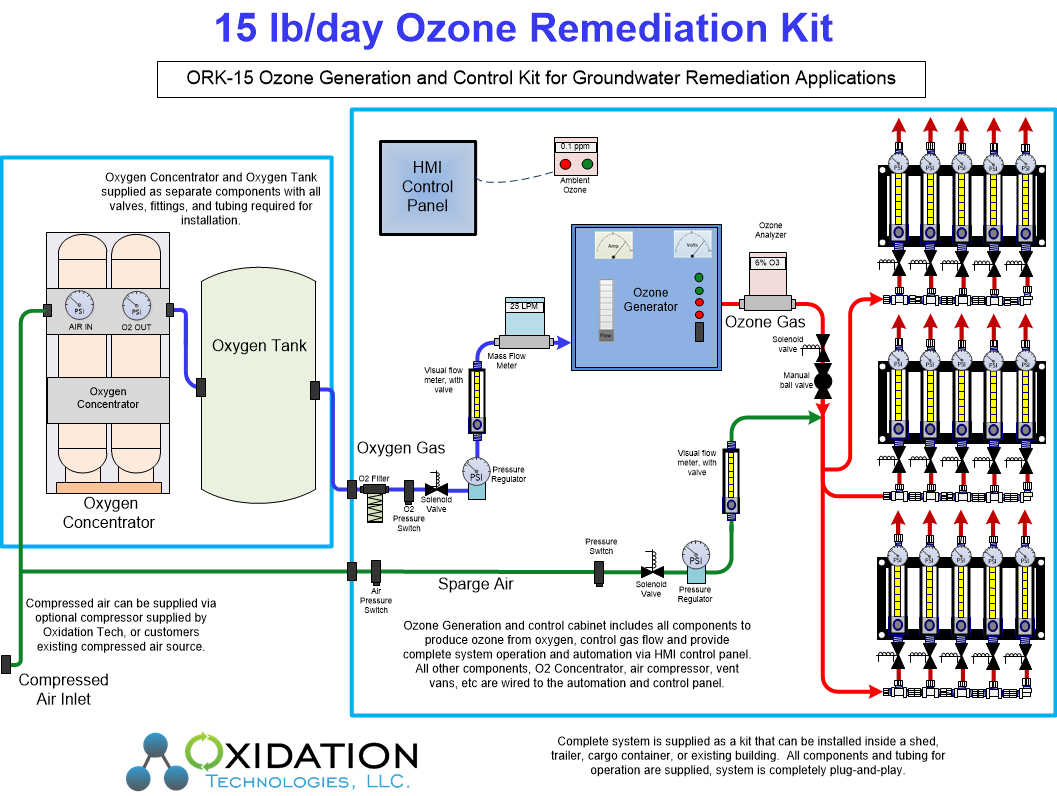

Ozone remediation system installed in a cabinet. Cabinet can be wall mounted or floor standing. All equipment necessary for ozone production and system control is provided inside the ozone system cabinet. An external, industrial oxygen generator, oxygen storage tank, and air compressor are provided to complete the system. All equipment is controlled from the main system cabinet. These modular systems are designed specifically for use in groundwater remediation applications.

Each system we build is custom built to our customer's specifications. We offer a variety of system sizes and configurations and options to fit most every application. Please review our products to get an idea of that is possible, and how we can integrate a system that will meet your needs. When you are ready for a custom quote or simply to discuss how ozone can work in this application call our application engineers, we are here to help.

ORK-15 Modular Ozone Remediation Kit Specifications:

-15 lb/day ozone production (283 g/hr)

-175 SCFH oxygen production

-12 CFM additional sparge air flow

-Manifold with 12 ozone outputs each controlled by solenoid valve

-45 PSI continuous oxygen/ozone pressure

-65 PSI max oxygen/ozone pressure

-100 PSI max air sparge pressure (breakthrough pressure)

Main System Components:

-Ozone System cabinet includes:

-283 g/hr Ozone Generator

-PLC based control system

-Touch Screen HMI (Human Machine Interface) Panel for operation

-Ozone leak Sensor

-Flow control for sparging air and oxygen

-Flow control manifold for well timing and control

-Complete automation of all external components

-175 SCFH Oxygen Generator

-80-gallon Oxygen Storage Tank

-All interconnecting piping, tubing and electrical connections

Optional Components:

-Rotary Screw Air Compressor with integrated air dryer

-Desiccant air dryer for sparge air

-Inline Ozone Analyzer

-Inline oxygen purity meter

-Inline oxygen mass flow meter

-Cellular telemetry capability

Ozone System Layout and Design:

All equipment required for operation is included with the standard kit. Compressed air can be supplied from customers existing compressed air source, or we will provide a compressor properly matched for the equipment. All tubing, valves, and interconnecting materials necessary will be included with this system. Simply set equipment into place, connect electrical power, and connect provided tubing and fittings into each other.

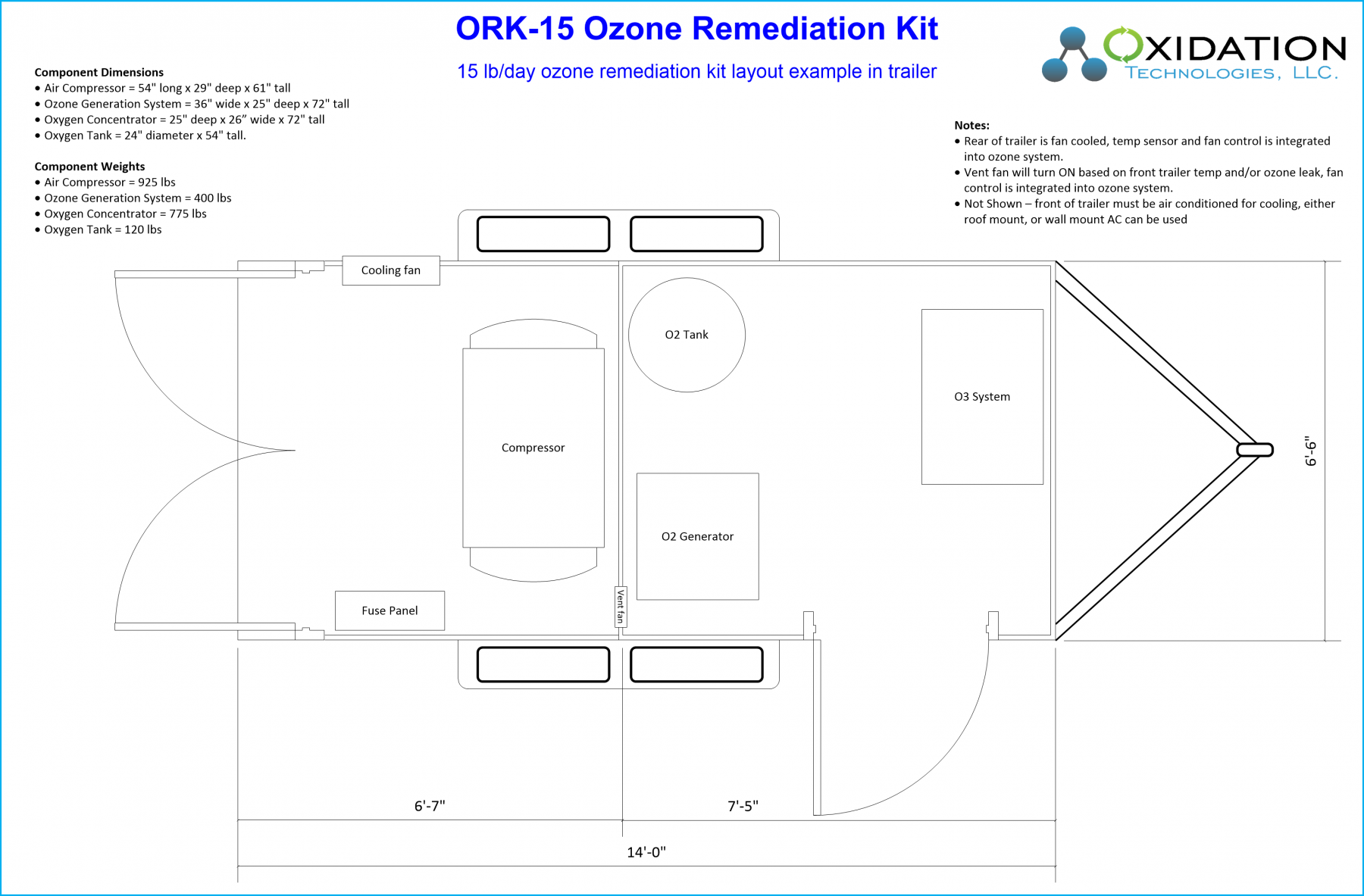

Trailer Layout

Trailers are commonly used to house remediation systems as they are portable, a temporary structure that can be placed on-site quickly without a great deal of prep time. The diagram below shows a typical installation of the ORK Ozone System inside a standard trailer.

Notes

The trailer is separated into 2 rooms. The large heat load of the air compressor is separated from the sensitive ozone generation and control equipment and kept in a fan cooled area in the rear of the trailer. The front of the trailer is cooled via a roof mounted or wall mounted air conditioning unit. This ensures the ambient room temperature around the air cooled ozone generator is controlled for consistent ozone production. This also keeps dust from damaging sensitive electrical equipment

The rear doors of the trailer open via swing hinges. This allows easy access to the rear of the trailer to service and maintain the large compressor

The front of the trailer is accessible via a walk-in door. This will allow service and maintenance of the smaller ozone generation and control equipment.

Cargo Container Layout

A cargo container may be used as a solid steel enclosure for the ozone equipment. Cargo containers are easily shipped internationally, and to many industrial sites. A 15 or 20 foot cargo container would give ample room for equipment and maintenance.

A typical cargo container would be designed similar to the trailer diagram shown above. Ensure there are 2 rooms, one for compressor, one for sensitive ozone generation equipment. There must be access to both areas of the trailer via swinging doors that are sufficient in size to install and service equipment.

Shed Layout

A shed or small building may be used to house the equipment as a more permanent structure. A shed is more attractive, and may be necessary to meet local building codes for longer term installs.

When using a shed to house ozone equipment it is normally designed with two halves, having access via large swinging doors to both halves.

Ozone System Central Cabinet:

The foundation of the ORK-15 Modular Ozone System is the ozone system cabinet. This cabinet houses all the ozone production and control equipment, along with complete system controls. Every external piece of equipment plugs into this cabinet for easy install, and complete automation of the entire system.

Ozone Cabinets provide the following standard equipment:

-283 g/hr ozone generator

-PLC based control system

-Touch Screen HMI (Human Machine Interface) Panel for operation

-Telemetry system – based on customers needs

-Ozone leak Sensor – will detect all ozone leaks in the room

-Flow control for sparging air and oxygen

-solenoid valve, pressure regulator, flow-meter

-Flow control manifold for well timing and control

-12 solenoid valves and 8 flow-meters for complete well control

-Complete automation of all external components

-Steel cabinet with fan cooling

Ozone System Controls:

The ORK-15 Modular Ozone system will be controlled by one central control system. This will control all components automatically for reliable and safe operation. The operation of the system is performed with simple to use touch screen interface. All well timing, operation, and logging information is also performed on this touch screen panel for convenience.

The complete system will be configured with equipment that may be provided by the customer, or by Oxidation Tech. In either case the ability to control and interface with this equipment will be available and very simple. Easy connections are provided for each piece of equipment. If external control for optional equipment is not required, simply turn that function OFF in the control panel.

External equipment controlled by standard control system:

-Air compressor ON/OFF signal to start or stop air compressor

-Auto-drain solenoid valve on compressor air tank timer

-Oxygen Concentrator ON/OFF

-Rear trailer temp sensor input

-Rear trailer humidity sensor input

-Rear trailer vent fan ON/OFF

-Front trailer vent fan ON/OFF

-Complete SVE system

-Optional control available

It is also possible to operate and monitor the system remotely via a telemetry system. The system can connect to the internet via wireless, wired, or cellular data connection. When operating system remotely every operational parameter available while at the actual control panel is also available remotely. Logged data can also be downloaded remotely for reporting purposes. The system can be set-up to send e-mails for alarm conditions.

Ozone Generator:

The heart of any ozone system is the ozone generator. We have worked for years to develop ozone generators that can handle the rugged and demanding environments, pressures, and operating requirements found in remediation applications. This system uses an air-cooled ozone generator to produce 283 g/hr of ozone from 175 SCFH oxygen at 4.1% by weight. Ozone generation is efficient and reliable with solid state electronics and a single durable ozone generation cell.

Ozone is produced under pressure. Ozone generation cell is rated for up to 100 PSI of pressure. Ozone generated under pressure is important as it eliminates the requirement to re-pressurize ozone with a secondary compressor or pump. Due to the high-pressure capability of this ozone generator and single ozone outlet from a single cell ozone leaks are almost complete eliminated.

Ozone Manifold:

The ozone manifold will distribute ozone gas to multiple wells. The standard manifold supplied with the ozone cabinet provides 12 outputs with 12 solenoid valves to allow full control of each valve. Any number of valves can be open simultaneously or individual valves can be open and cycle through each consecutively.

Image shown for reference purposes

The entire manifold is mounted inside the ORK-15 enclosure for protection and easy long-term maintenance. All plumbing carrying ozone is located on the wall, no hinges or moving parts are involved, this helps lower the number of long-term ozone leaks. All stainless steel fittings with stainless steel and Teflon plumbing is used.

Custom configurations are available to add well outputs, or add flow-meters to outputs to create zones. Any configuration is possible and available with the same control from our easy to use touch screen interface.

Further ozone manifold abilities are possible with customers equipment. Customers will commonly split each ozone output into 2, 3, or 4 outputs essentially making each of the ORK-15 systems ozone outputs into a zone that delivers ozone gas to 4 outputs, multiplying the 12 outputs to 48 total well outputs.

Oxygen Generator:

The Oxygen Generator supplied with the ORK-15 Modular Ozone System is an OGSI OG-175 industrial oxygen generator. This is an industrial type oxygen generator with large steel sieve beds and direct-acting solenoid valves for valving. All components are of the highest quality, and each component can be rebuilt individually keeping your maintenance costs low for the long term,

This oxygen generator provides oxygen at pressures of at least 45 PSI and up to 65 PSI. This ensures ozone gas can be generated under pressure and flow to the well without re-pressurizing the ozone gas. This is important as re-pressurizing ozone will generate additional heat and destroy ozone. This system eliminates the extra compressor needed when oxygen gas is produced at lower pressures.

The oxygen generator must be bolted to the floor, plugged into power from the ORK-15 system, and plumbed for air inlet and oxygen outlet. All interconnecting tubing and cords are supplied with the system.

Oxygen Storage Tank:

An oxygen storage tank is required to buffer oxygen supply and demand from the OG-175 Oxygen Generator. A tank is supplied with the system of adequate size for the oxygen generator. Valving is installed and tubing is provided to make simple connections from the oxygen generator, to the ORK-15 Modular Ozone System.

Air Compressor:

Compressed air is required for oxygen production and for sparging air. Compressed air can be supplied by an existing compressed air source, the customers own supplied compressor, or a compressor supplied by Oxidation Tech that is sized specifically for this system.

The air compressor supplied by Oxidation Tech is a rotary screw compressor designed for 100% duty cycle in harsh environmental conditions. A built-in refrigerant air is used to remove moisture from the air and ensure that both the oxygen generator can operate reliably, and the ozone manifold remains dry to eliminate nitric acid build-up.

Install Example:

The image below shows ORK-4 Modular Ozone System installed inside a trailer by one of our east coast distributors, RES (Remediation Equipment and Services).

If you are considering a Modular ozone system but are not sure about installation considerations, we can put you in touch with one of our partner distributors who can install a system in your existing structure. We can also offer maintenance and PM services in most USA locations.

Click on image to enlarge

Ozone Remediation System Options:

The ORK-15 Modular Ozone System is customizable to any requirements. We offer standard configurations in our marketing information and provide as much detail and information as reasonably possible. However, as each system is built when ordered, we have a great deal of customization possible. See details below for a few options

Inline Oxygen Purity Analyzer - Real-time oxygen purity can be measured and displayed on the HMI screen with the addition of an oxygen purity analyzer. This will provide a positive feed-back on the quality of oxygen used for ozone production.

Oxygen Mass Flow Meter - Oxygen flow can be measured and displayed digitally on the HMI screen to show actual oxygen/ozone flow into the soil formations. An oxygen mass flow meter provides actual oxygen flow information regardless of changing pressures making an easy check of actual oxygen flow. This information can also be logged for reporting purposes.

Air Mass Flow Meter - Sparging Air flow can be measured and displayed digitally on the HMI screen to show actual Air Sparging flow into the soil formations. An air mass flow meter provides actual air flow information regardless of changing pressures making an easy check of actual air flow. This information can also be logged for reporting purposes.

Inline Ozone Analyzer - To provide additional operational information an inline ozone analyzer can be added to the ozone system to measure the ozone production of the ozone generator in real time. When set-up with an oxygen mass flow meter the actual output of ozone can be measured and recorded real time. This is ideal for pilot tests, or applications were recording and reporting is critical. This information can also be logged for reporting purposes.

SVE (soil vapor extraction) System - SVE systems are commonly added to ozone sparge systems to treat contaminated soils. An SVE system can be supplied as a Modular piece of equipment to be installed in customers enclosure, or controls can be incorporated to control the customers SVE system and provide a complete system with ozone and SVE controls in one location.

Manifold Configuration - Ozone sparge flow is controlled by a flow manifold. The standard ORK-15 system is designed with 12 individual solenoid valves to direct ozone flow to 12 wells. These outlets can be configured with additional flowmeters to create zones, for example, if 4 flowmeters were added to each of the 8 outputs a total of 48 wells could be treated in 12 separate zones. Also, additional (or fewer) solenoid valve outputs can be provided. This customization is essentially unlimited.

Air Sparge Upgrade - Air is added to the ozone/oxygen air stream to increase the permeation of ozone in soil and groundwater and increase the radius of influence. The ORK-15 system is provided with a compressor sized for 15 CFM of additional sparge air. If additional sparge air is required a larger compressor can be provided to meet that need

H2O2 Addition - Hydrogen Peroxide dosage and injection system can be added to the standard ozone sparge system. This will create the AOP reaction if done properly. When H2O2 injection is added a separate room of the cabinet is added for the storage, dosage, and distribution panel for the H2O2 system.

Ozone Accessories:

Oxidation Tech offers a full line of accessoires that may be needed for your system installtion or operation.

Ozone Sparging Diffusers - Bubble ozone gas into water efficiently with stainless steel diffuser that creates 20-micron bubbles. Sintered stainless steel is a reliable choice for a sparge point

Ozone Delivery Tubing - We carry Teflon tubing in various sizes. Teflon tubing is the best choice for a long-lasting yet flexible tubing to deliver ozone to the wells.

Well Components - Well components such as well caps, packers and riser pipes are available. Contact us for details on your configurations and equipment needed

Ozone Leak sensor – wall mount - Remote mount ozone leak sensor can be used and integrated into the ozone system. This is used when ozone lvels in an adjacent building or occupied space may rise due to ozone sparging in the groundwater below that area.

Ozone leak sensor – handheld - Handheld ozone monitor can be used for leak detection or personal safety.

Downloads:

About Groundwater Remediation

ORK Brochure

Components Diagram

ORK Kit Layout

Trailer Diagram

Ozone Information

Why use Oxidation Technologies:

There are many ozone companies that will provide equipment, or complete turnkey systems. So, what makes our systems better? Experience! Plain and simple we have been on-site and operated ozone remediation systems for many years.

Details matter, and we know what details are important what are not. Producing ozone is easy, however, building a reliable and effective ozone system is not easy. There are many parts that need to work together perfectly for many hours without human oversight. Our extensive experience allows us to make sure the details of your ozone system are right, to ensure maximum run-time and reliability.

Let us help you ensure your system will operate for many years reliably and effectively.

| Manufacturer | Oxidation Technologies |

|---|---|

| Call For Price | No |

| Listing Description | Modular Ozone System 15 lb/day ozone cabinet (283 g/hr) 12 well outputs standard 100 PSI max sparge pressure 45 PSI operational pressure |

| Feed Gas | Oxygen |

| Nominal Gas Flow Rate | 17 CFM total oxygen/ozone/air flow to wells |

| Operating Pressure | 45 PSI |

| Max Pressure | 100 PSI |

| Gas Connections | 3/8" compression fittings x 12 |

| Datalogging | Yes |

| Dimensions (LxWxH) | 62" tall x 42" wide x 24" deep |

| Operational Temperature Range | 0 - 100-deg F |

| Power Requirements | 220-VAC 3-phase power |

| Lead Time | 6-8 weeks typical |

| Warranty | 1 Year |

| Country of Origin | USA |