Workhorse Profile-15

*PLEASE NOTE: This product has been discontinued. If your're looking for an alternative, we highly recommend the MAX-8.*

15 SCFH oxygen production at 7 PSI is produced by a Workhorse-15 Profile oxygen concentrator module.

Call For Price

*PLEASE NOTE: This product has been discontinued. If your're looking for an alternative, we highly recommend the MAX-8.*

The Workhorse-15 Profile Oxygen System offers the same superior performance of the standard Workhorse model, but in less space. Workhorse-15 technology can be offered as a replacement for older, existing systems where space considerations are important. Workhorse utilizes Advanced Technology Fractionator (ATF).

ATF Oxygen Modules incorporate proven pressure swing adsorption (PSA) principles into a unique patented design, which allows these systems to be compact, efficient, rugged, and lower in cost. ATF modules offer unparalled design flexibility and enable applications where on-site/on-board oxygen generation was previously impractical.

Features

Reliable Oxygen Production

Environmentally Tolerant

Compact and Lightweight

Constant Delivery Pressure

Low Operating Cost

Eliminates Need for External Product Tank

Optional Oxygen Concentration Monitor

Product Characteristics

|

Performance Data: Product Flow Oxygen Delivery Pressure |

15 SCFH 7 PSI (48 kPa) |

| Product Concentration | Up to 95% |

| Product Dew Point | -100°F (-73°C) |

| Dimensions (DxH) |

17 x 11 x 22 inches 43 x 28 x 56 cm |

| Weight | 67 lbs (30 kg); Additional 1 lb. with optional oxygen monitor |

|

Physical Connections Product Gas Outlet |

1/8" FNTP |

| Ambient Operating Conditions |

Locate the oxygen concentrator system in a well-ventilated area that is protected from weather elements. Inside room or enclosure: Temps should remain between 40°F (4°C) and 130°F (54°C) In storage: Temps should remain between 0°F (-18°C) and 140°F (60°C) |

| Control Power Requirements (Single Phase) | 120 V ~ ± 10%, 60 Hz or 208-240 V ~ ± 10%, 60 Hz or 220-240 V ~ ± 10%, 50 Hz |

| Typical Power Consumption | ~450 W |

Typical Applications

Manufacturing

- Jewelry/Brazing/Sodering

- Glas Work/Blowing

Environmental

- Ozone (Generator) Feed Gas

- Environmental Remediation

- Waste/Water Treatment

Additional

- Fish Farming

- Cosmetic

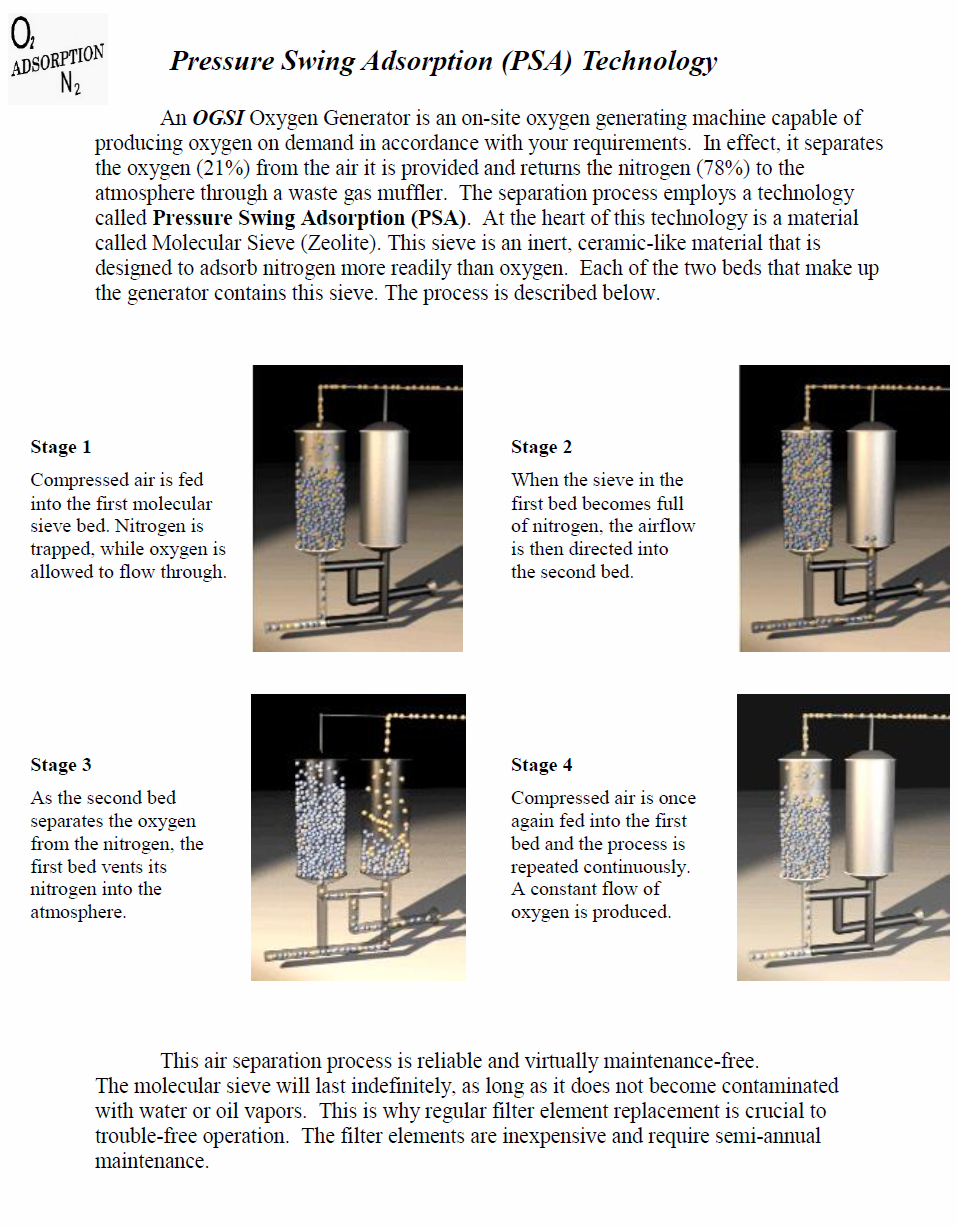

What is Pressure Swing Adsorption (PSA)

Clean, dry compressed air is fed into the first molecular sieve bed. Nitrogen is adsorbed, while oxygen is allowed to flow through. When the sieve in the first bed becomes full of nitrogen, the airflow is then directed into the second bed. As the second bed separates the oxygen from the nitrogen, the first bed vents its nitrogen into the atmosphere. Compressed air is once again fed into the first bed, and the process is repeated continuously. A constant flow of oxygen is reliably produced.

Downloads:

| Manufacturer | Air Sep |

|---|---|

| Call For Price | No |

| Listing Description | 15 SCFH @ 7 PSI |

| Oxygen Production | 15 SCFH |

| Internal Compressor | Yes |

| O2 Delivery PSI | 9 PSI |

| Nominal Gas Flow Rate | 15 SCFH |

| Operating Pressure | 7 PSI |

| Max Pressure | 9 PSI |

| Gas Connections | 1/8" Female NPT |

| Dimensions (LxWxH) | 17" wide x 11" deep x 22" tall |

| Operational RH Range | NA |

| Operational Temperature Range | NA |

| Power Requirements | 120 V ~ ±10%, 60 Hz or 208 – 240 V ~ ±10%, 60 Hz or 220 – 240 V ~ ±10%, 50 Hz |

| Lead Time | In Stock |

| Warranty | 1 Year |

| Country of Origin | USA |

| Description | Turnkey unit with built-in compressor |